Foaming light diffusion plate, preparation method and application thereof

A light diffusion plate and cell technology, applied in the field of diffusion plates, can solve the problems of difficult cell size uniformity, poor foamed light diffusion plate, uneven density of foamed light diffusion plate, etc., and achieve uniform cell size. , to expand the applicable fields, and the overall mechanical performance is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

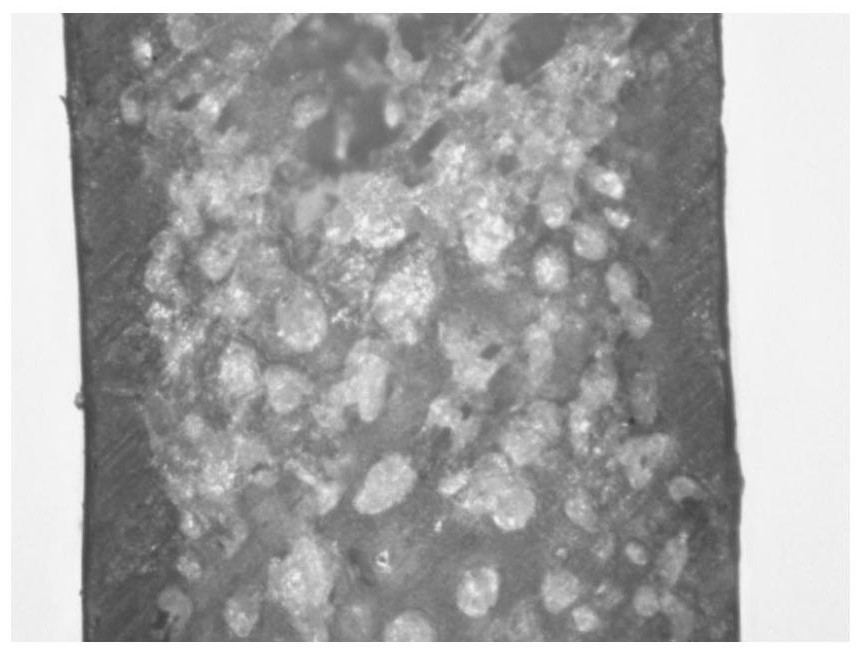

Image

Examples

preparation example Construction

[0023] The preparation method of the foamed light diffusion plate provided by the present invention comprises the following steps:

[0024] S1, mixing and melting polystyrene, a carbonyl-containing polymer, and a nucleating agent to obtain a blend, wherein the melting temperature of the carbonyl-containing polymer is ≤200°C;

[0025] S2, injecting supercritical carbon dioxide into the blend, and then extruding and foaming to obtain a foamed light diffusion plate.

[0026] In step S1, selecting a carbonyl-containing polymer as one of the blending components can increase the solubility of carbon dioxide in the blend, improve the absorption of carbon dioxide by the blend, and increase the nucleation of cells when the blend is foamed The number of points to obtain a denser cell structure. Moreover, compared with a single polymer, choosing a blend composed of carbonyl-containing polymers can increase the degree of supersaturation of the blend system, so as to improve the foaming a...

Embodiment 1

[0049] Take 40kg of polystyrene, 7kg of polylactic acid, and 3kg of talc powder (with a particle size of 2 μm) and put them into a twin-screw extruder for full shear and uniform mixing to form a molten state. The heating temperature of the second zone is 200°C, the heating temperature of the second zone is 200°C, the heating temperature of the third zone is 210°C, the heating temperature of the fourth zone is 210°C, the heating temperature of the fifth zone is 210°C, and the heating temperature of the sixth zone is 215 ℃, the heating temperature of the seventh area is 215 °C, the heating temperature of the eighth area is 210 °C, the heating temperature of the ninth area is 210 °C, the heating temperature of the screen changer is 200 °C, and the heating temperature of the static mixer is 190 °C.

[0050] Under the condition of extrusion rate of 20kg / h, supercritical carbon dioxide is introduced with injection pressure of 8MPa and gas injection rate of 60g / h and stirred evenly. ...

Embodiment 2

[0053] The only difference between Example 2 and Example 1 is that 35 kg of polystyrene, 10 kg of polyacrylamide, and 3 kg of talcum powder (with a particle size of 2 μm) are used.

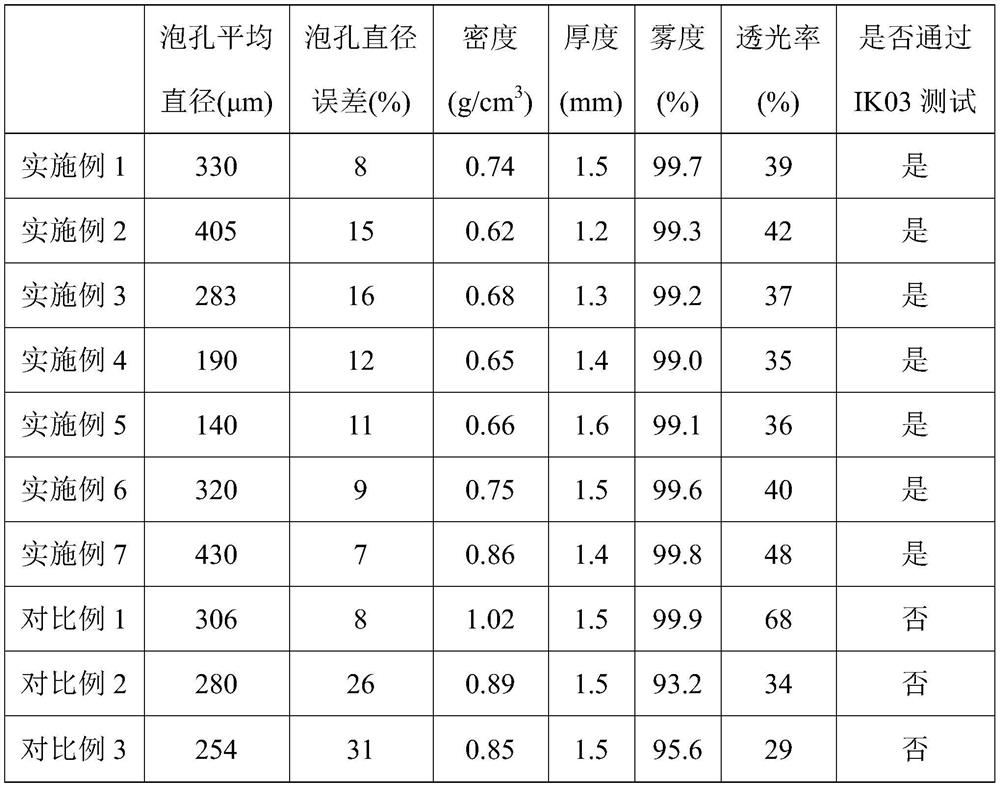

[0054] The performance test of the prepared foamed light diffusion plate was carried out, and the specific results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Cell diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com