Preparation method of sensitive film for detecting chloride ion optical fiber sensor in concrete pore solution

A concrete, chloride ion technology, applied in chemical instruments and methods, instruments, luminescent materials, etc., can solve the problems of photobleaching of fluorescence intensity of fluorescent probes, inaccurate measurement of chloride ion concentration, easy falling off of fluorescent indicators, etc. Good water performance, excellent mechanical properties and chemical stability, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

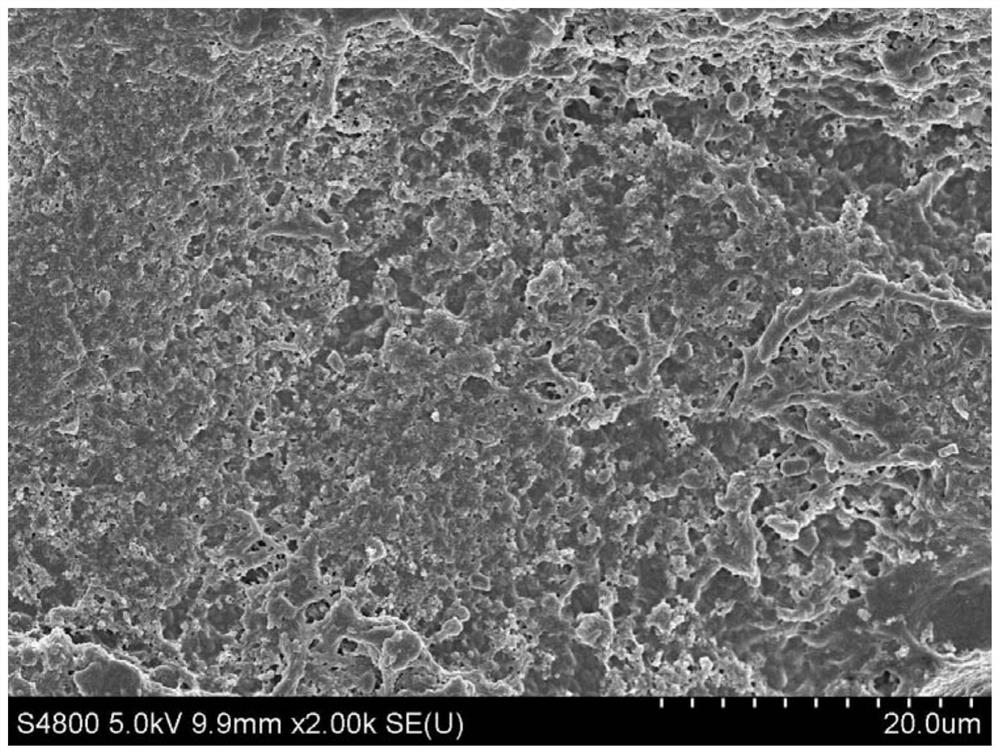

Image

Examples

preparation example Construction

[0027] In one or more examples of this embodiment, the preparation method of the optical fiber sensor sensitive membrane for detecting chloride ions in the concrete pore solution includes the following specific steps:

[0028] (1) Preparation of precursor solution: 1 to 5 parts by weight of polytetrafluoroethylene, polyvinylidene fluoride PVDF or polyimide, and 0.1 to 1.5 parts by weight of graphene are dissolved in 10 to 50 parts by weight of an organic solvent In dimethyl sulfoxide DMSO, ultrasonication for 1-3 hours, and magnetic stirring for 0.5-1.0 hours to obtain a precursor solution;

[0029] (2) Preparation of mother liquor: Add 3 to 7 parts by weight of graft modifier to the above precursor solution, stir vigorously in an oil bath at 60 to 80°C for 6 to 10 hours to obtain a uniform and transparent solution; dissolve in 2 to 5 In DMF of twice the weight part, stir at room temperature for 10-60min to obtain the mother liquor solution;

[0030] (3) Preparation of spray ...

Embodiment

[0040] (1) Preparation of precursor solution: 1 to 5 parts by weight of polytetrafluoroethylene, polyvinylidene fluoride PVDF or polyimide, and 0.1 to 1.5 parts by weight of graphene are dissolved in 10 to 50 parts by weight of an organic solvent In dimethyl sulfoxide DMSO, ultrasonication for 1-3 hours, and magnetic stirring for 0.5-1.0 hours to obtain a precursor solution;

[0041] (2) Preparation of mother liquor: Add 3 to 7 parts by weight of polymethyl methacrylate PMMA and polyvinyl pyrrolidone PVP to the above precursor solution, and stir vigorously in an oil bath at 60 to 80°C for 6 to 10 hours to obtain a uniform and transparent solution; dissolved in 2 to 5 parts by mass of DMF, and stirred at room temperature for 10 to 60 minutes to obtain a mother liquor solution;

[0042] (3) Preparation of spray film solution: add 2-10 parts by weight of Al in the above-mentioned mother liquor solution 2 o 3 or SiO 2 and a certain weight portion of chloride ion fluorescent pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com