Method for preparing titanium-based polyester through DMT process

A technology of titanium-based polyester and polyester is applied in the field of preparing titanium-based polyester by DMT method, which can solve the problems of easy yellowing and poor dispersibility of polyester catalyst, and achieve high dispersibility, avoid agglomeration and good compatibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A method for preparing a sheet-like titanium-based polyester catalyst. After mixing terephthalic acid, ethylene glycol, and n-butyl titanate at a molar ratio of 1:1.5:0.01, the temperature is 150°C and the pressure is 0.01MPa. After reacting for 0.5h under the same conditions, the temperature was raised to 200°C and the reaction was continued until the degree of esterification reached 70%. The reaction was terminated, filtered while hot, and then pulverized and ground to obtain a sheet-shaped titanium-based polyester catalyst with an average particle size of 0.5 μm.

Embodiment 2~6

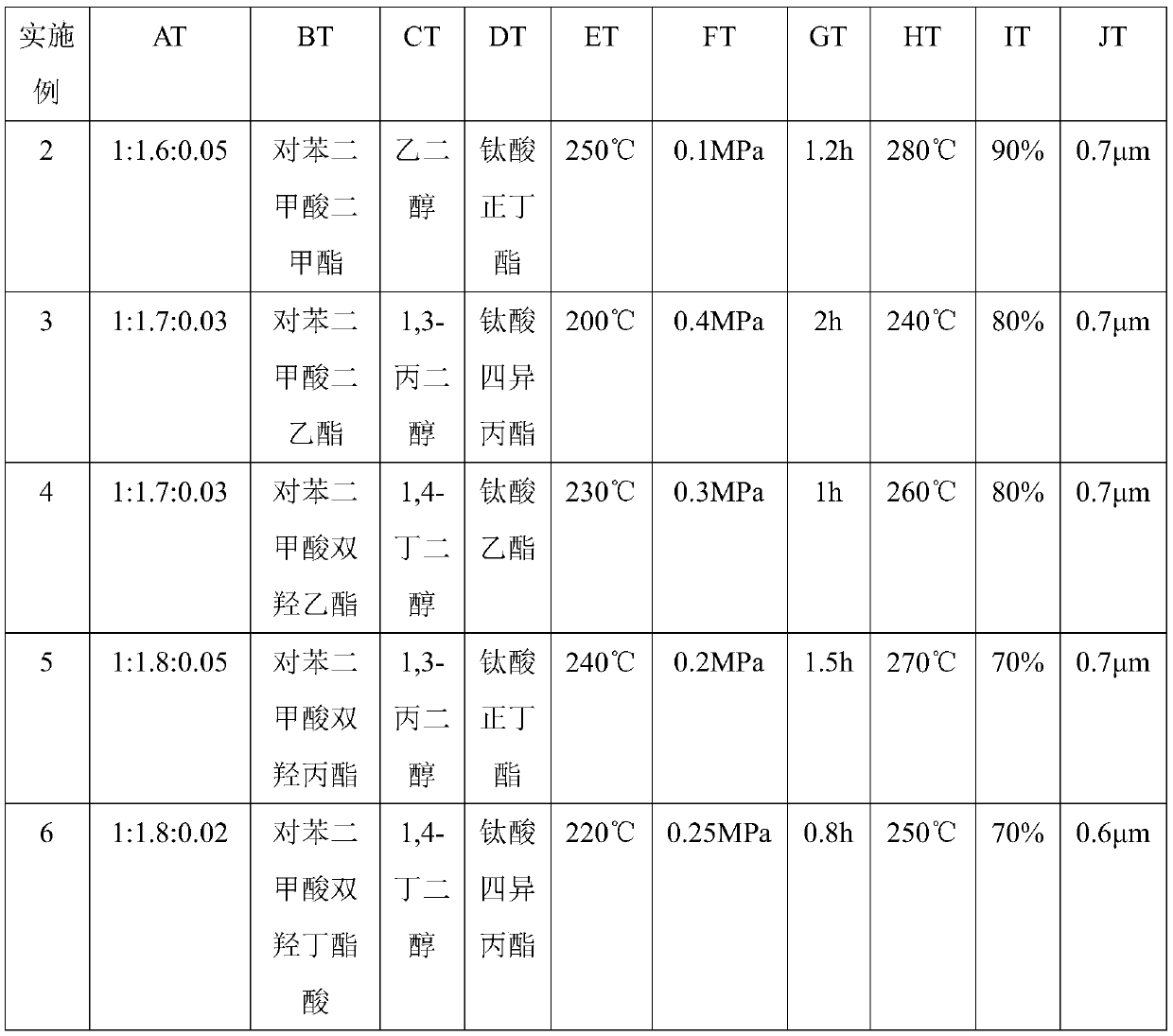

[0046] A preparation method of a sheet-shaped titanium-based polyester catalyst, after mixing BT, CT and DT with a molar ratio of AT, reacting GT at a temperature of ET and a pressure of FT, then raising the temperature to HT to continue the reaction until esterification When the degree reaches IT, the reaction is terminated, filtered while hot, and then pulverized and ground to obtain a sheet-shaped titanium-based polyester catalyst with an average particle size of JT.

[0047]

Embodiment 7

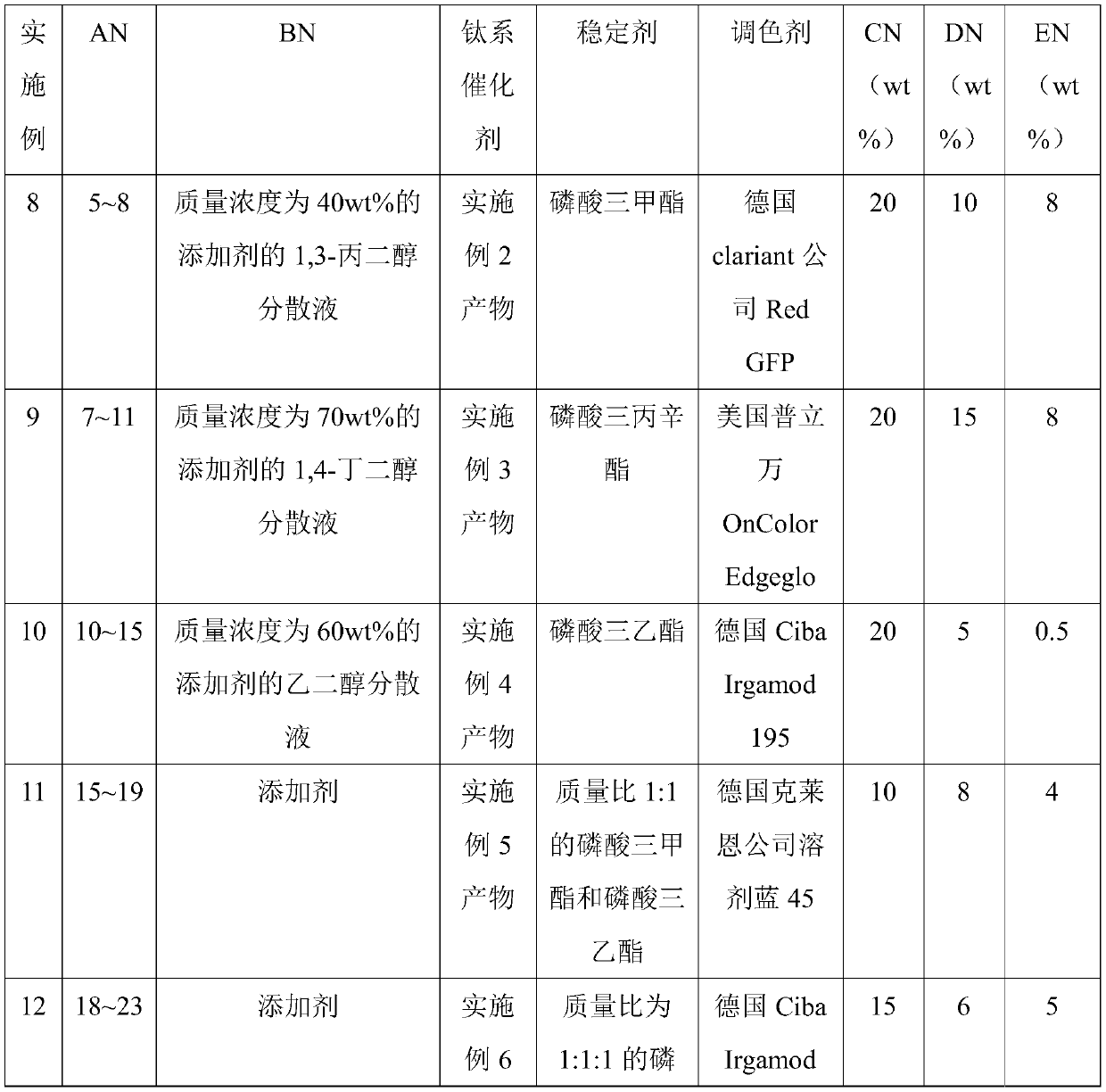

[0049] A preparation method of a polyester titanium catalyst composite material system, firstly adding a mass concentration of 30wt% The ethylene glycol dispersion of the flaky titanium-based polyester catalyst, and then uniformly stirred and cooled to obtain a polyester titanium-based catalyst composite material system, wherein the flaky titanium-based polyester catalyst is prepared by Example 1, polyester The mass content of the sheet-shaped titanium-based polyester catalyst in the titanium-based catalyst composite material system body is 20 wt%.

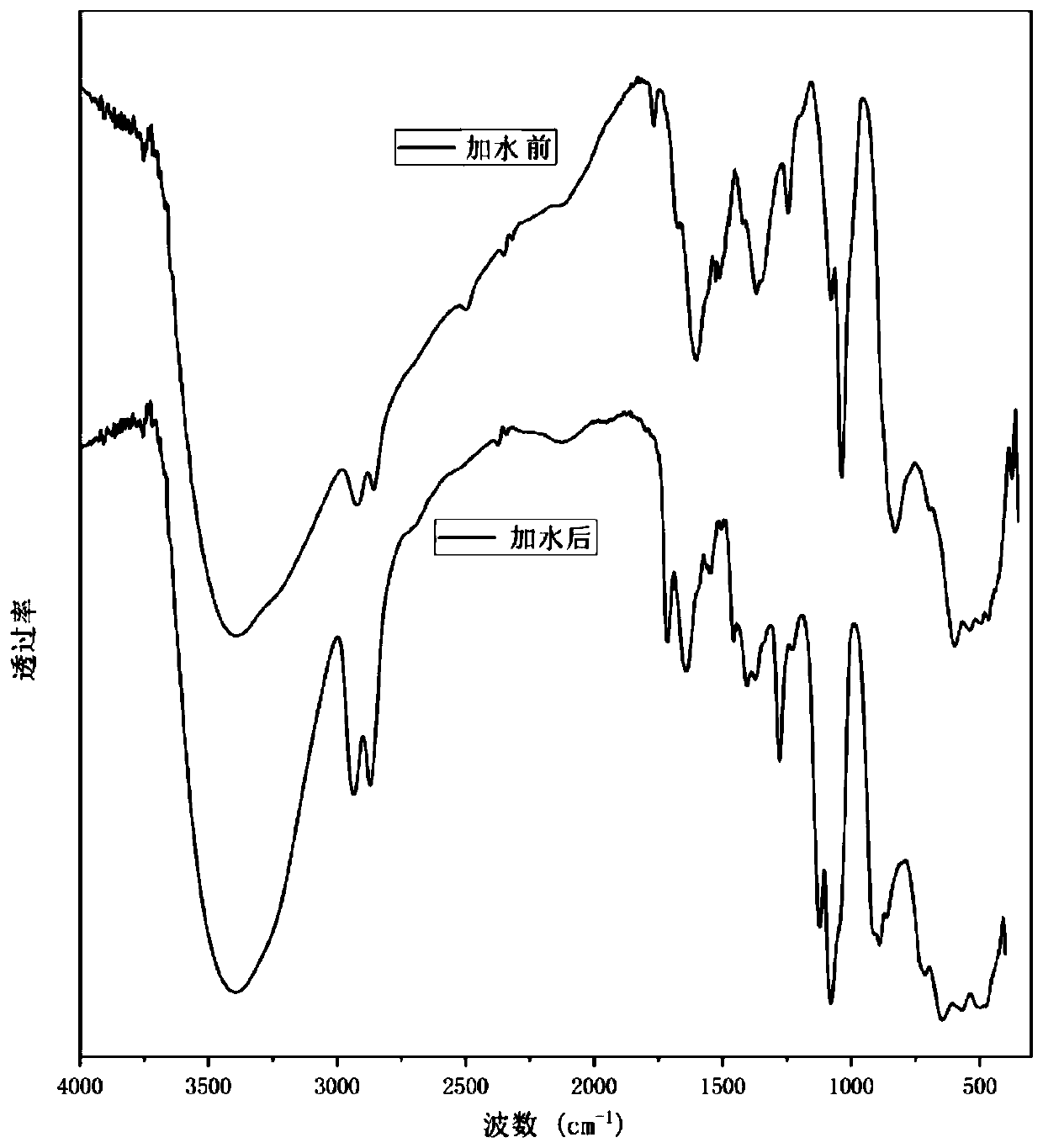

[0050] Disperse 0.1g polyester titanium catalyst composite material system in 30mL water, heat and stir at 70°C for 3h, wash and dry the residual solid with absolute ethanol, and then perform FTIR characterization of the sample, as shown in figure 1 As can be seen from the figure, the polyester titanium series catalyst composite system sample in the present invention does not have much change in the crystal structure and character...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com