Formula of nylon hose material

A nylon and hose technology, applied in the field of preparation and production of polymer materials, can solve the problems of limited supply, high price, limited output, etc., and achieve the effects of good dimensional stability, good low temperature flexibility, and stable extrusion molding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The formula is as follows: 100 parts of copolymerized nylon PA610 / 613 (where PA613 accounts for 10% of the copolymerized nylon), 10 parts of plasticizer N-butylbenzenesulfonamide, 10 parts of impact modifier EPDM-g-MA, antioxidant 1681.5 parts, antioxidant 1098 1.5 parts.

[0018] Add the copolymerized nylon PA610 / 613, antioxidant, and impact modifier EPDM-g-MA into the high mixer according to the ratio required by the formula, and stir for 8 minutes under the condition of 400r / min. After the materials are completely mixed, pass The feeder is fed into the twin-screw extruder at a constant speed, and the plasticizer is fed in at a calculated speed through the liquid feeding port reserved in the extruder with a liquid metering pump to ensure that the ratio meets the formula requirements. All materials are melted and mixed uniformly by twin-screws, then extruded, cooled, granulated, dried and packaged to obtain the final product.

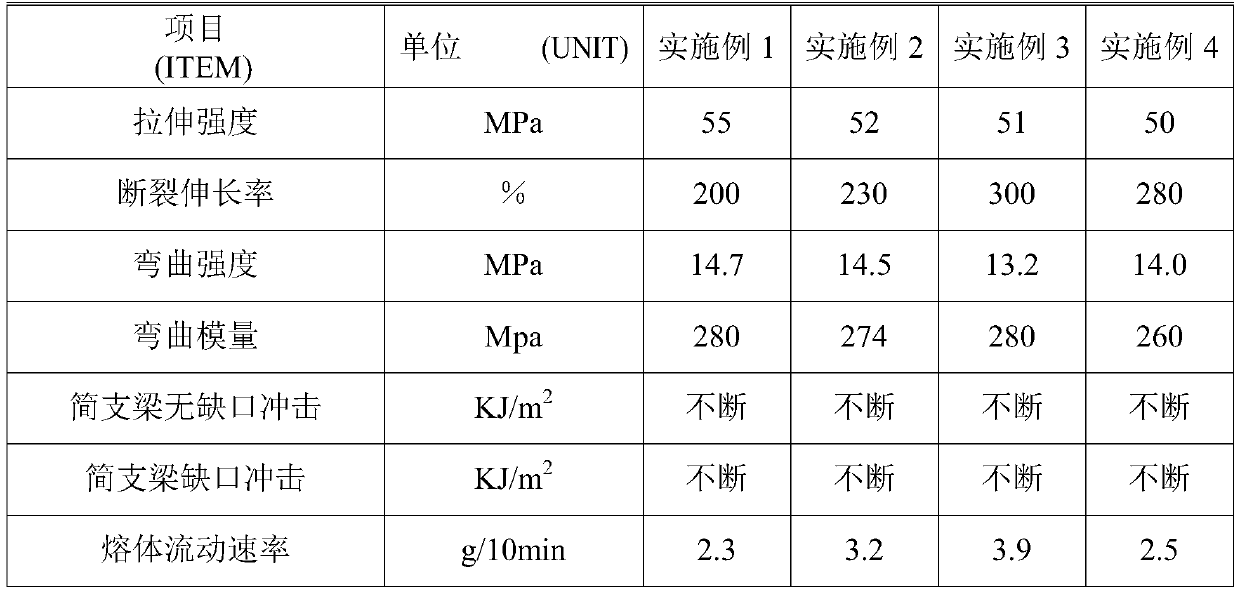

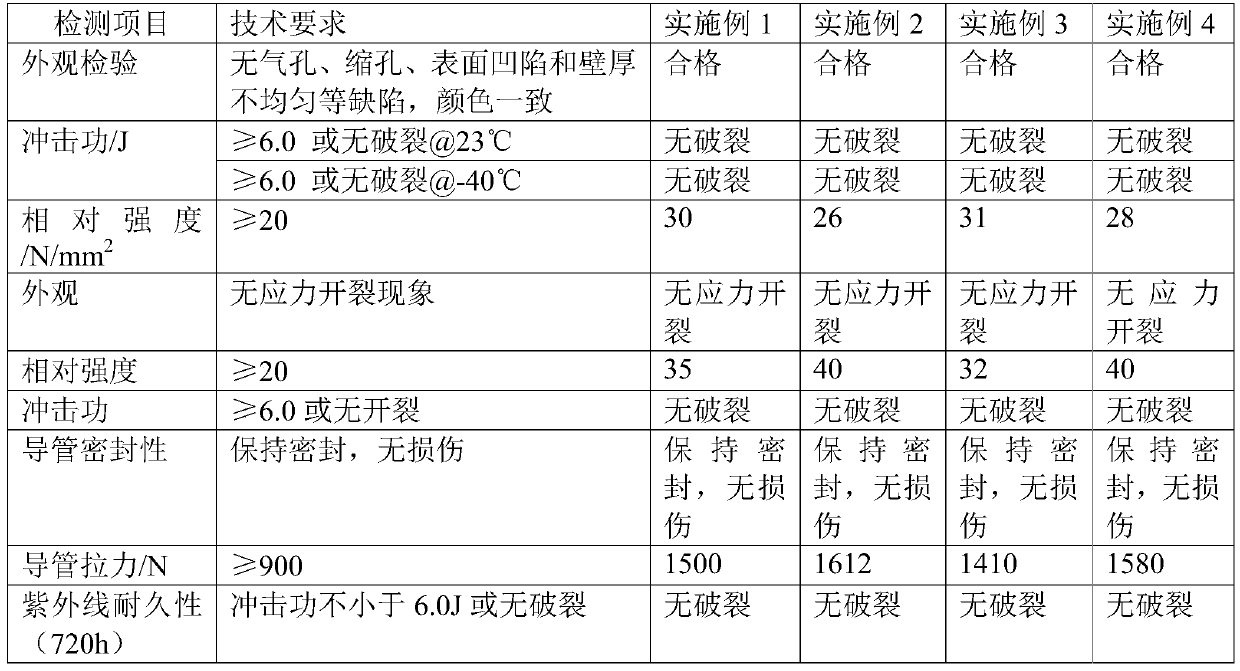

[0019] The mechanical properties of the ...

Embodiment 2

[0021] The formula is as follows: 100 parts of copolymerized nylon PA610 / 613 (where PA613 accounts for 15% of the copolymerized nylon), 10 parts of plasticizer N-butylbenzenesulfonamide, 15 parts of impact modifier EPDM-g-MA, antioxidant 1682 parts, antioxidant 1098 2 parts.

[0022] Add the copolymerized nylon PA610 / 613, antioxidant, and impact modifier EPDM-g-MA into the high mixer according to the ratio required by the formula, and stir for 8 minutes under the condition of 400r / min. After the materials are completely mixed, pass The feeder is fed into the twin-screw extruder at a constant speed, and the plasticizer is fed in at a calculated speed through the liquid feeding port reserved in the extruder with a liquid metering pump to ensure that the ratio meets the formula requirements. All materials are melted and mixed uniformly by twin-screws, then extruded, cooled, granulated, dried and packaged to obtain the final product.

[0023] The mechanical properties of the prep...

Embodiment 3

[0025] The formula is as follows: 100 parts of copolymerized nylon PA612 / 613 (where PA613 accounts for 10% of the copolymerized nylon), 10 parts of plasticizer N-butylbenzenesulfonamide, 15 parts of impact modifier SEBS-g-MA, antioxidant 168 2 parts, antioxidant 1098 2 parts.

[0026] Add the copolymerized nylon PA612 / 613, antioxidant, and impact modifier SEBS-g-MA into the high mixer according to the proportion required by the formula, and stir for 8 minutes under the condition of 400r / min. After the materials are completely mixed, pass The feeder is fed into the twin-screw extruder at a constant speed, and the plasticizer is fed in at a calculated speed through the liquid feeding port reserved in the extruder with a liquid metering pump to ensure that the ratio meets the formula requirements. All materials are melted and mixed uniformly by twin-screws, then extruded, cooled, granulated, dried and packaged to obtain the final product.

[0027] The mechanical properties of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com