Oil-resistant, insulating, acid and alkali resistant, and high temperature resistant multifunctional safety shoe

A multi-functional and safety shoe technology, applied in soles, footwear, applications, etc., can solve problems such as lack of acid and alkali resistance and insulation, complex preparation process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

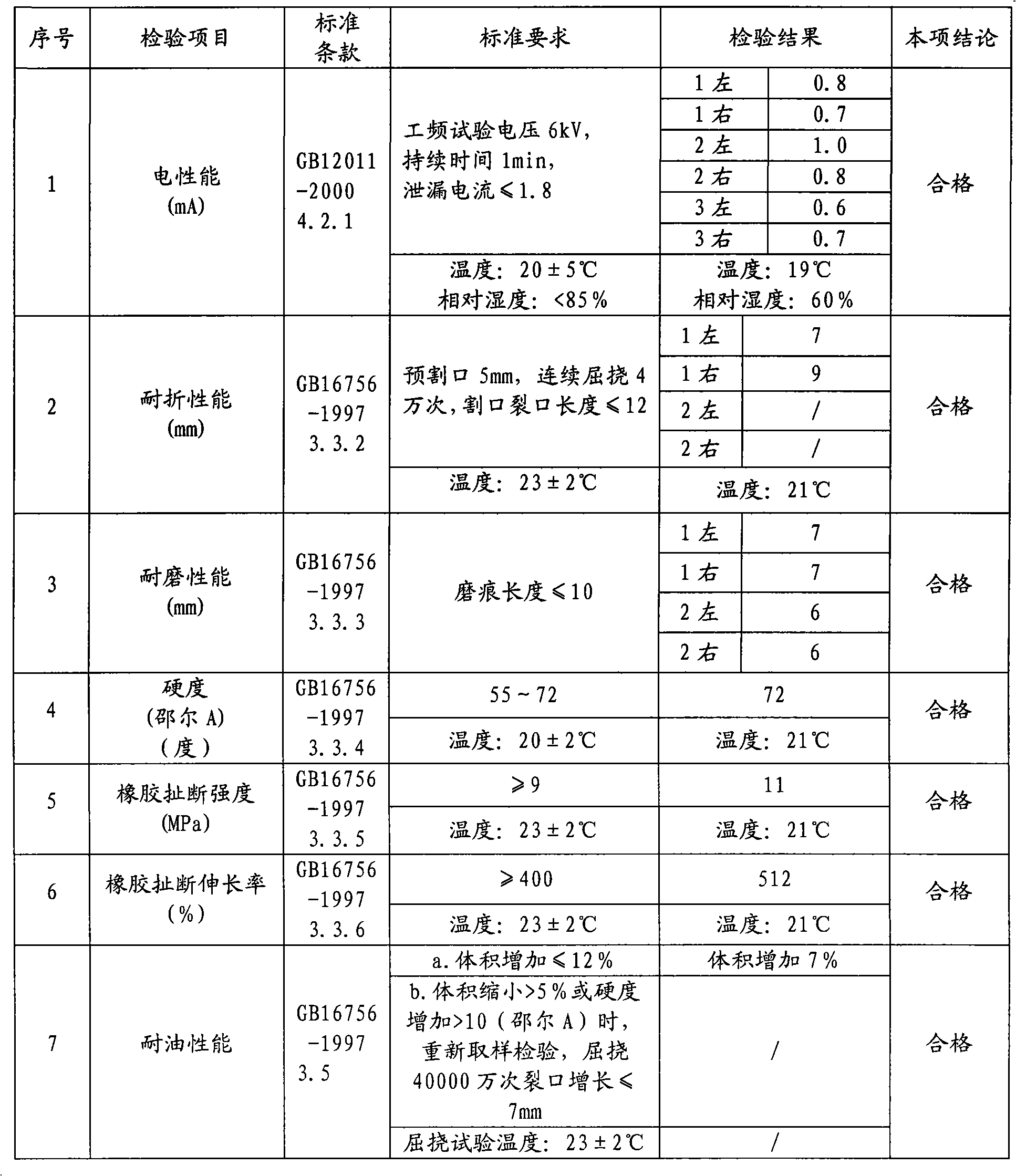

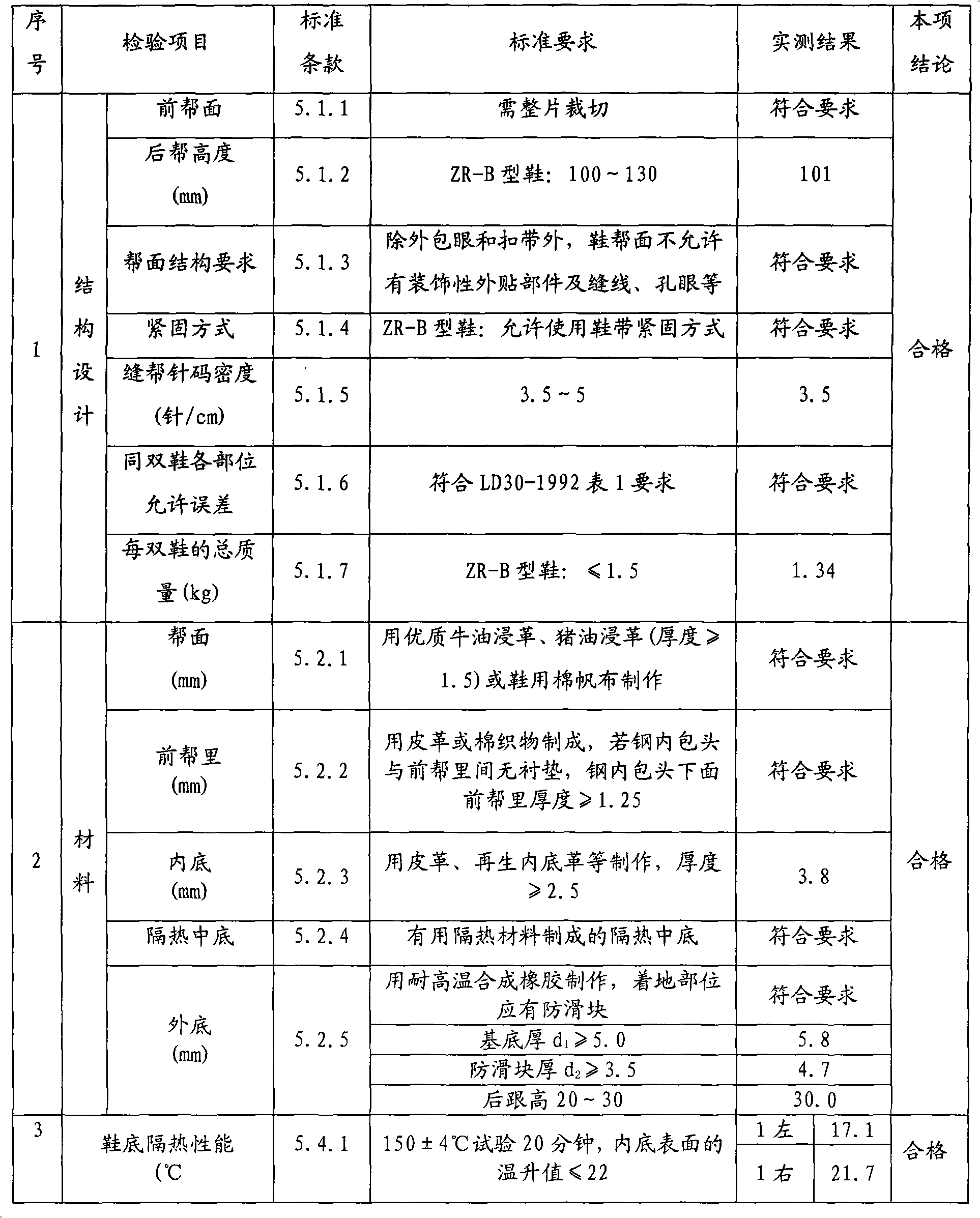

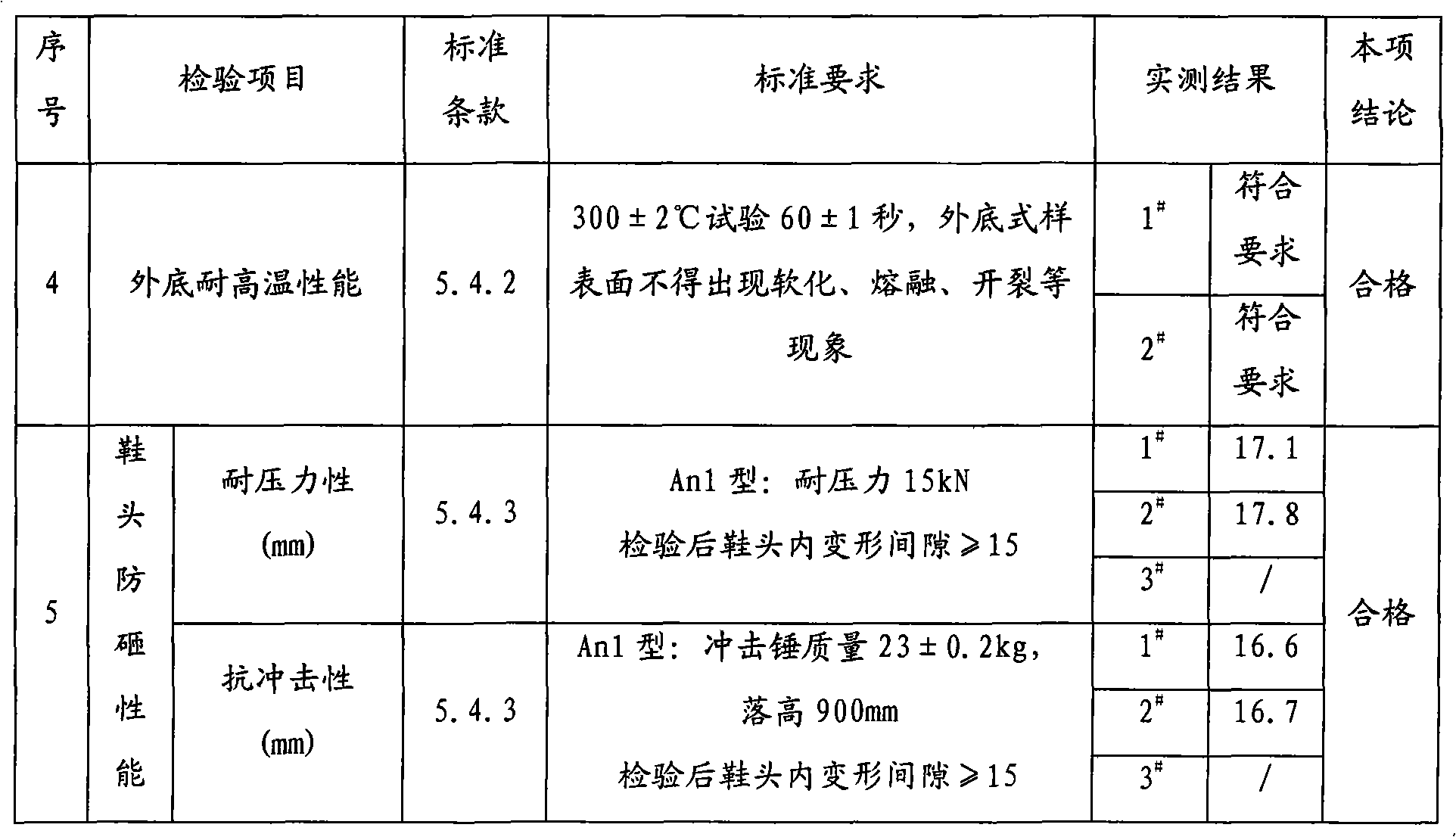

Image

Examples

Embodiment Construction

[0041] An oil-resistant, insulating, acid-alkali-resistant, high-temperature-resistant multifunctional safety shoe, the raw material composition and production process of the sole are as follows:

[0042] 1. The composition of raw materials is as follows:

[0043] Oil-resistant rubber nitrile rubber 35 kg,

[0044] Synthetic rubber styrene-butadiene rubber 15 kg,

[0045] Carbon black 20 kg,

[0046] clay 10 kg,

[0048] Stearic acid 1.4 kg,

[0049] 5 kg of dibutyl ester,

[0050] Accelerator M 0.5 kg,

[0051] Accelerator DM 0.5 kg,

[0052] 1 kg of sulfur,

[0053] TMTP 0.2 kg,

[0054] Vaseline 1.4 kg.

[0055] 2. The production process is as follows:

[0056] The above raw materials are prepared in proportion for later use,

[0057] Mix the prepared raw materials into synthetic raw film,

[0058] Put the raw film into the sole mold,

[0059] Use a hydraulic press to apply a pressure of 66 kg to the film, and vulcanize it at a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com