Preparation method of biomass-based molecularly imprinted composite membrane for selectively separating tetracycline

A technology of molecular imprinting and tetracycline, applied in separation methods, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problems of poor hydrophilicity, low selectivity of molecular imprinting membranes, non-biodegradable, etc., and achieve easy recovery and selection Strong adsorption capacity, solve the effect of difficult recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

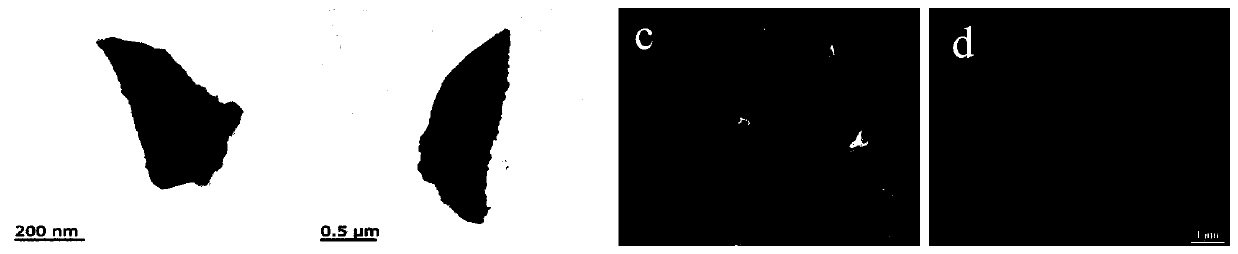

[0051] S1, preparation of modified biomass activated carbon nanoparticles (k-ACNPs):

[0052] First, 0.5 g of biomass-based activated carbon nanoparticles (ACNPs) and 3 mL of γ-(methacryloxy)propyltrimethoxysilane (kh570) were dispersed in a mixed solution including 80 mL of ethanol and 20 mL of water, and then the mixture was placed in Heat and reflux at 80°C for 24 hours. After the reaction, wash with ethanol and distilled water three times respectively, centrifuge the modified nanoparticles at 10,000 rpm for 5 minutes, and dry in vacuum at 60°C to obtain k-ACNPs.

[0053] S2. Preparation of nano-activated carbon doped cellulose and chitosan hybrid (k-AC@CA / CS) basement membrane:

[0054] First, 0.9 g of k-ACNPs prepared in S1 was added to 40 mL of 0.1 g chitosan (CS), 3 g cellulose acetate (CA), 0.5 g polyvinyl alcohol (PVA) and 0.2 g polyvinylpyrrolidone (PVP) In the dimethyl sulfoxide solution; the mixed solution was heated in a constant temperature water bath at 50°C an...

Embodiment 2

[0061] S1, preparation of modified biomass activated carbon nanoparticles (k-ACNPs):

[0062] First, 1.0 g of biomass-based activated carbon nanoparticles (ACNPs) and 3 mL of γ-(methacryloxy)propyltrimethoxysilane (kh570) were dispersed in a mixed solution including 80 mL of ethanol and 20 mL of water, and then the mixed solution was Heat and reflux at 80°C for 24 hours; after the reaction, wash with ethanol and distilled water three times respectively, centrifuge the modified nanoparticles at 10,000 rpm for 10 minutes, and dry in vacuum at 65°C to obtain k-ACNPs;

[0063] S2. Preparation of nano-activated carbon doped cellulose and chitosan hybrid (k-AC@CA / CS) basement membrane:

[0064] First, 0.9 g of k-ACNPs prepared in S1 was added to 40 mL of 0.1 g chitosan (CS), 3 g cellulose acetate (CA), 0.5 g polyvinyl alcohol (PVA) and 0.2 g polyvinylpyrrolidone (PVP) In the dimethyl sulfoxide solution, the mixed solution was heated in a constant temperature water bath at 45°C and ...

Embodiment 3

[0072] S1, preparation of modified biomass activated carbon nanoparticles (k-ACNPs):

[0073] First, 1.5 g of biomass-based activated carbon nanoparticles (ACNPs) and 3 mL of γ-(methacryloxy)propyltrimethoxysilane (kh570) were dispersed in a mixed solution including 80 mL of ethanol and 20 mL of water, and then the mixture was placed in Heat and reflux at 80°C for 24 hours; after the reaction, wash with ethanol and distilled water three times respectively, centrifuge the modified nanoparticles at 10,000 rpm for 5 minutes, and dry in vacuum at 70°C to obtain k-ACNPs;

[0074] S2. Preparation of nano-activated carbon doped cellulose and chitosan hybrid (k-AC@CA / CS) basement membrane:

[0075] First, 0.9 g of k-ACNPs prepared in S1 was added to 40 mL of 0.1 g chitosan (CS), 3 g cellulose acetate (CA), 0.5 g polyvinyl alcohol (PVA) and 0.2 g polyvinylpyrrolidone (PVP) In the dimethyl sulfoxide solution, the mixed solution was heated in a constant temperature water bath at 40°C and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com