A kind of ultra-long silicon nitride/silica core-shell structure nanofiber and its preparation method

A technology of silica and core-shell structure, applied in the direction of fiber chemical characteristics, conjugated artificial filaments, artificial filaments made of inorganic materials, etc., can solve the problem of increasing the overall cost of silicon nitride nanofibers, increasing process complexity and difficulty, The cost of rare earth metal salts is high, and the preparation process is simple and easy to implement, the preparation method is simple and efficient, and the effect is relatively easy to obtain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of ultra-long silicon nitride / silicon dioxide core-shell nanofibers provided by the present invention comprises the following steps:

[0031] (1) Preparation of precursor solution: weigh a certain mass of silicon source and add it to the polar solvent, stir and disperse at 20-100 ° C for 1-8 h, and add a certain mass of polymer-based carbon source after fully dispersed, Continue to stir for 4-12h, let stand or defoaming under reduced pressure for later use.

[0032] (2) Precursor molding: the precursor solution obtained in the step (1) is subjected to a casting film method or a spinning method to solidify and shape to obtain a precursor of a highly dispersed silicon source / polymer-based carbon source mixture.

[0033] (3) heat treatment of precursor: put the precursor obtained in the step (2) into a high-temperature furnace, carry out nitridation treatment under nitrogen atmosphere, drop to room temperature after the heat treatment process is comp...

Embodiment 1

[0044] S11: Preparation of precursor solution: 30 g of SiO 2 Nanoparticles (particle size: 7-40 nm) were added to 900 ml of N,N-dimethylformamide solvent, and ultrasonically dispersed for 1 h at room temperature. 70g of polyacrylonitrile (molecular weight M w =50,000), stirred and dispersed at 55°C for 12h to form a homogeneous mixed solution, filtered through an 800-mesh filter for use.

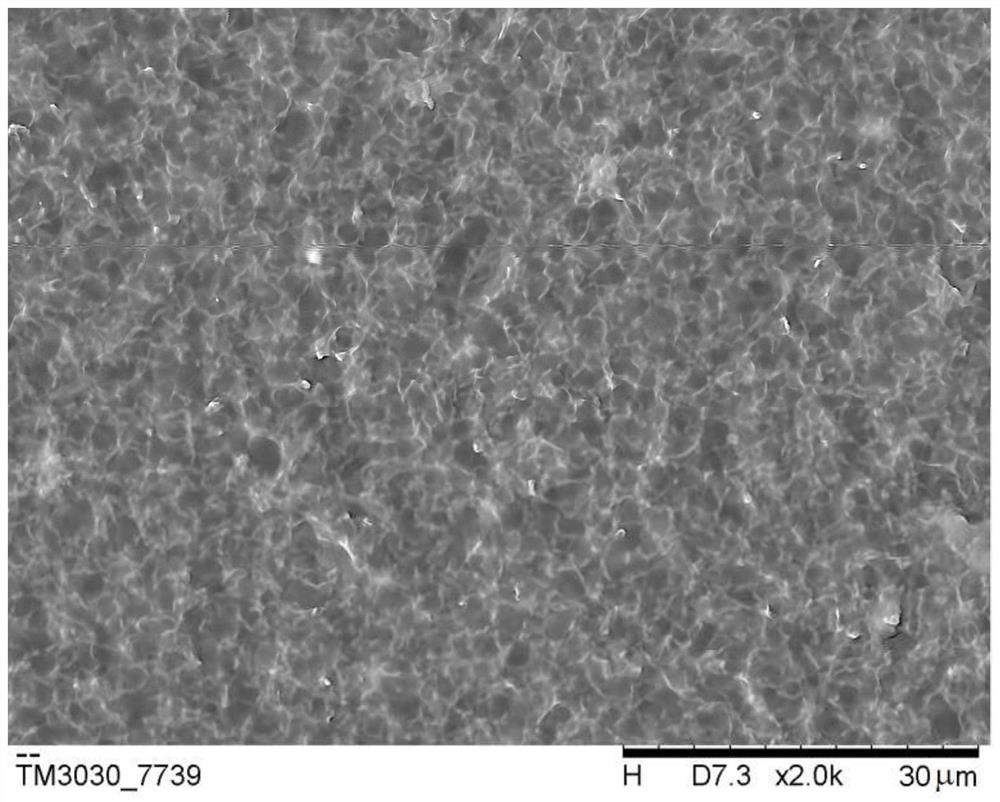

[0045] S12: Precursor forming: pump the precursor solution in step S11 into the metering pump for casting film, extrude the die 1000mm, the mechanical speed is 500m / h, the microscopic morphology of the obtained film-like precursor is shown in figure 1 shown.

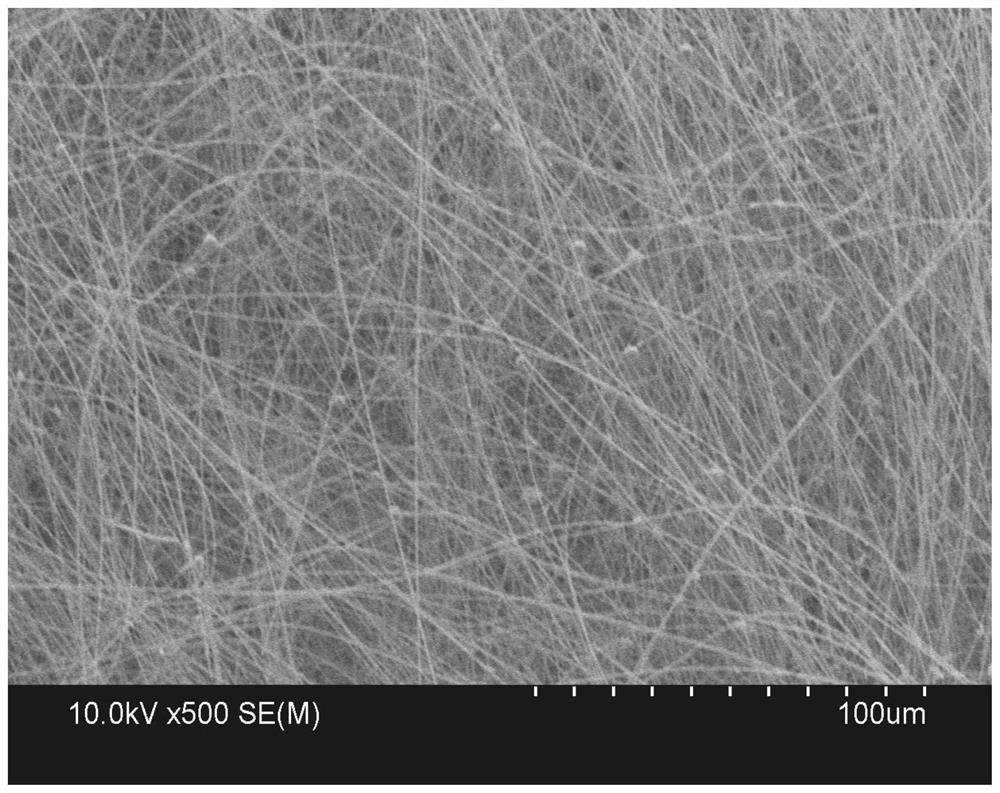

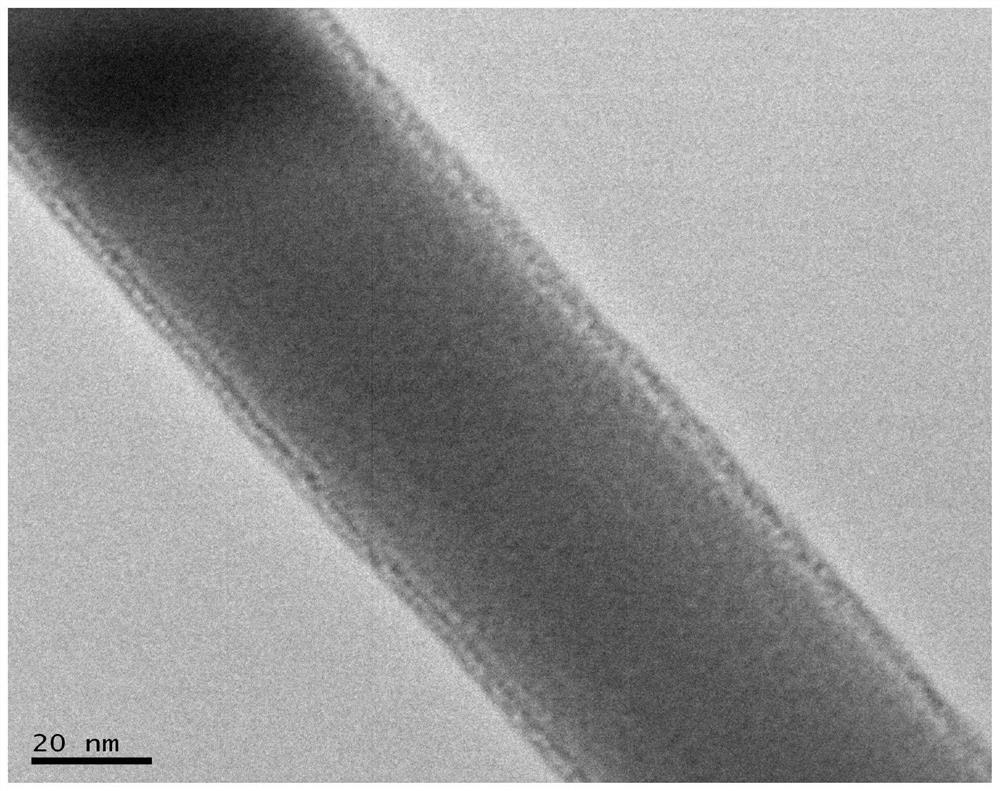

[0046] S13: Heat treatment of the precursor: place the film-like precursor in step S12 in a high-temperature furnace, heat it up to 1400°C at a heating rate of 7°C / min in a nitrogen atmosphere, and perform nitridation for 2 hours to obtain ultra-long Silicon nitride / silica core-shell nanofibers, the morphology and structure of which...

Embodiment 2

[0049] The high-temperature nitridation time in step S13 in Example 1 is adjusted to 3h, and the remaining steps are the same as those in Example 1, so that ultra-long silicon nitride / silicon dioxide core-shell nanofibers can be obtained.

[0050] The diameter of the silicon nitride / silicon dioxide core-shell nanofibers obtained in this example is slightly increased, distributed in the range of 80-200 nm, and the aspect ratio is large, greater than 1000.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com