Preparation method of woven bag with strong anti-aging effect

A woven bag, anti-aging technology, used in textiles, fabrics, bag-making operations, etc., can solve the problem of high cost and achieve the effect of improving the anti-aging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

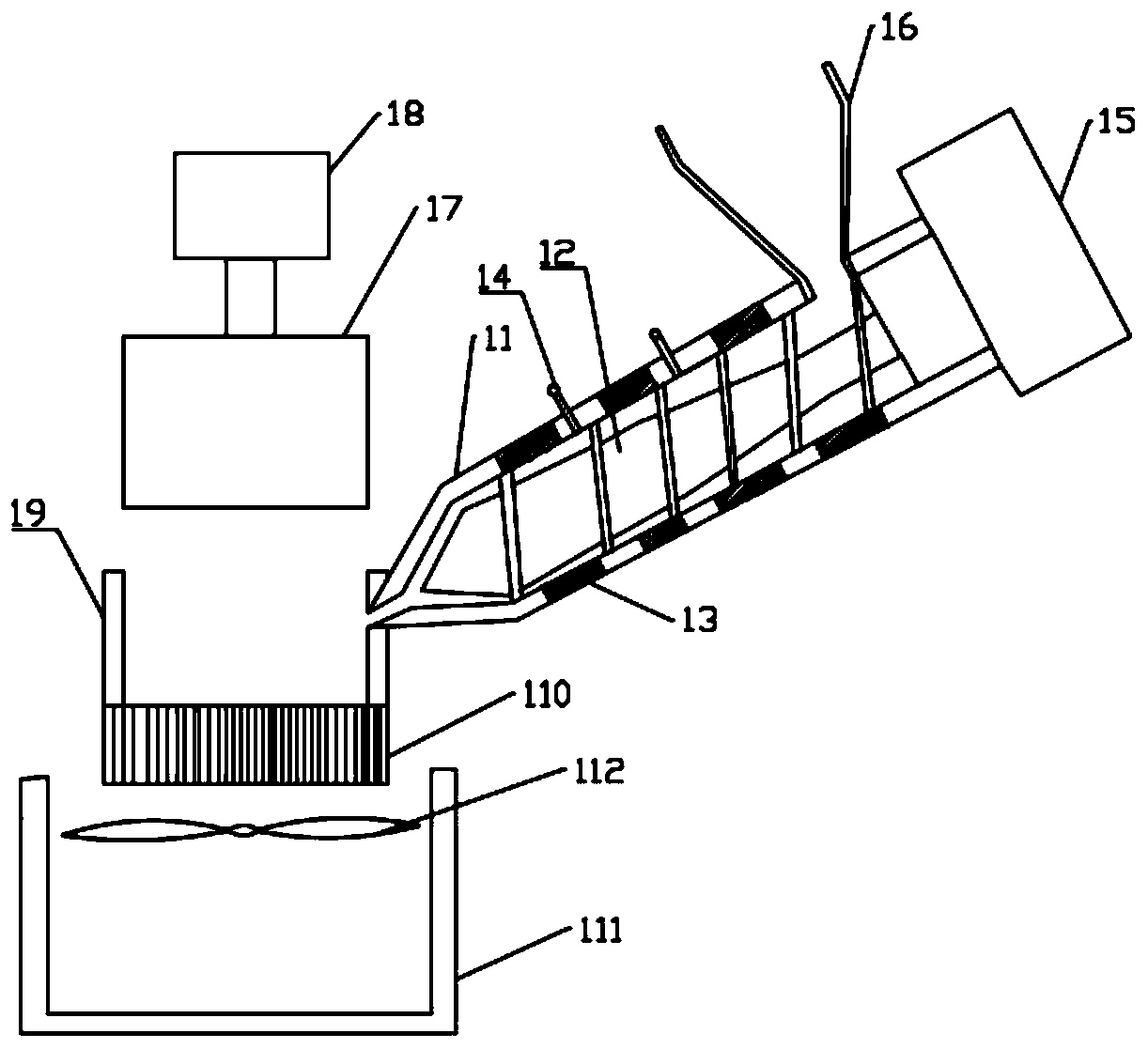

[0026] A preparation method of a woven bag with strong anti-aging effect, which comprises the following steps:

[0027] S1 is made of plastic film: 5-15 parts by weight of stone powder, 40-60 parts by weight of recycled plastic, 1-3 parts by weight of masterbatch, 5-13 parts by weight of the first wood powder, and 0.1-0.3 parts by weight of the first tourmaline powder , 0.3-0.8 parts by weight of o-hydroxybenzophenone are mixed with 1-5 parts by weight of β-nucleating agent at a high temperature of 250°C to melt and mix to obtain a molten material, which is extruded through a die to become a plastic film, and the water tank is cooled to shape ;

[0028] S2 stretching the film obtained in step S1;

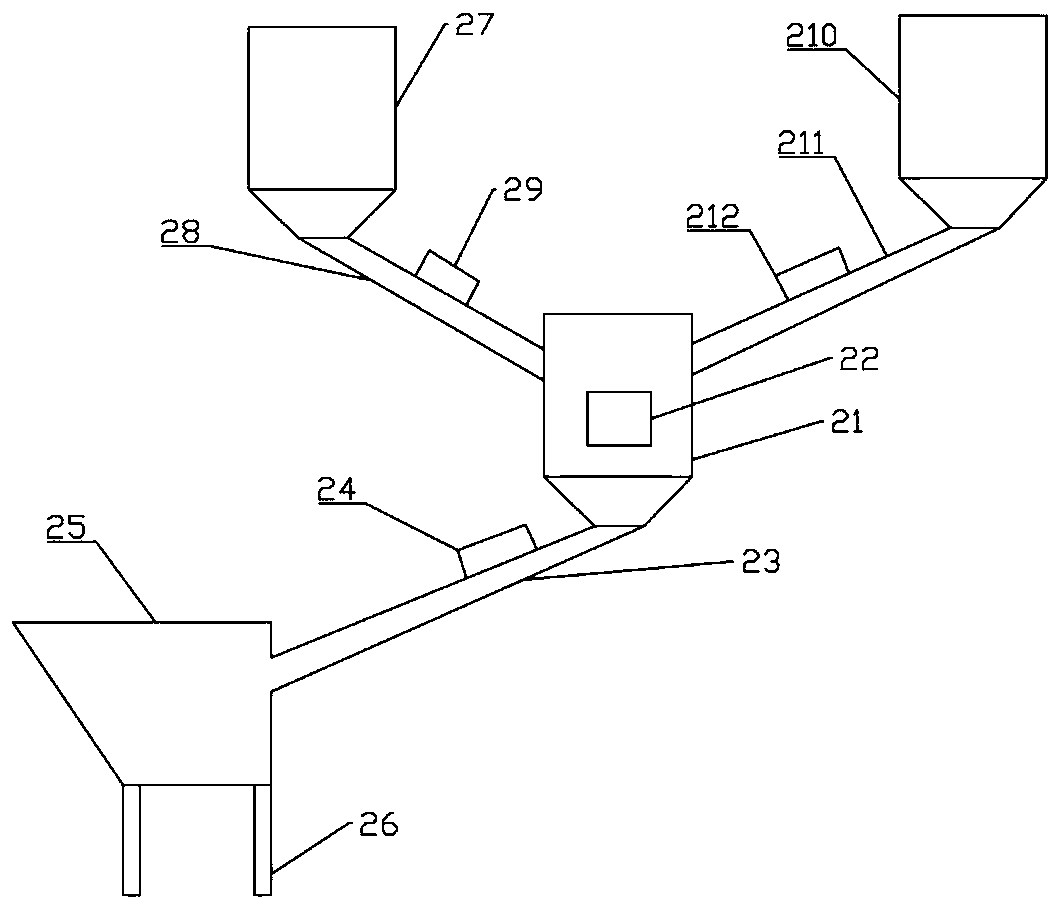

[0029] S3 smearing treatment: preparation of smear liquid, 1-3 parts by weight of porous powder quartz powder, 0.3-0.8 parts by weight of second tourmaline powder, 5-13 parts by weight of second wood powder, 3-10 parts by weight of acrylic acid emulsion and 10-10 parts by weight of...

Embodiment 1

[0054] A preparation method for a woven bag with strong anti-aging effect, which comprises the following steps:

[0055] S1 Treatment of recycled plastics: After sorting, crushing, cleaning, sterilizing and drying waste polypropylene plastic products, add 1% of its weight of sodium hydroxycellulose under hot melt at 200°C and mix them to obtain recycled plastics;

[0056] Made of S2 plastic film: 10 parts by weight of stone powder, 60 parts by weight of recycled plastics, 1 part by weight of masterbatch, 10 parts by weight of the first wood powder, 0.3 parts by weight of the first tourmaline powder, and 0.3 parts by weight of o-hydroxybenzophenone After mixing, it is melted and mixed with 3 parts by weight of β-nucleating agent at a high temperature of 250°C to obtain a molten material, which is extruded through a die to become a plastic film, and the water tank is cooled to shape;

[0057] S2 Stretching the film obtained in step S1, the tension of the stretching process is 10...

Embodiment 2

[0063] A preparation method for a woven bag with strong anti-aging effect, which comprises the following steps:

[0064] S1 Treatment of recycled plastics: After sorting, pulverizing, cleaning, sterilizing and drying waste polypropylene plastic products, add 3% of its weight of sodium hydroxycellulose under hot melt at 200°C and mix them to obtain recycled plastics;

[0065] Made of S2 plastic film: 5 parts by weight of stone powder, 50 parts by weight of recycled plastics, 3 parts by weight of masterbatch, 5-parts by weight of the first wood powder, 0.2 parts by weight of the first tourmaline powder, and 0.8 parts by weight of o-hydroxybenzophenone After being mixed with 1 part by weight of β-nucleating agent, it is melted and mixed at a high temperature of 250°C to obtain a molten material, which is extruded through a die to become a plastic film, and the water tank is cooled to shape;

[0066] S2 Stretching the film obtained in step S1, the tension of the stretching process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com