Preparation method of styrene-acrylonitrile copolymer

A technology of acrylonitrile and styrene, which is applied in the field of preparation of styrene-acrylonitrile copolymers, can solve problems affecting the quality of SAN resin, uneven polymer composition, and uneven temperature of the polymerization tank, so as to ensure composition stability, The effect of eliminating local unevenness and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

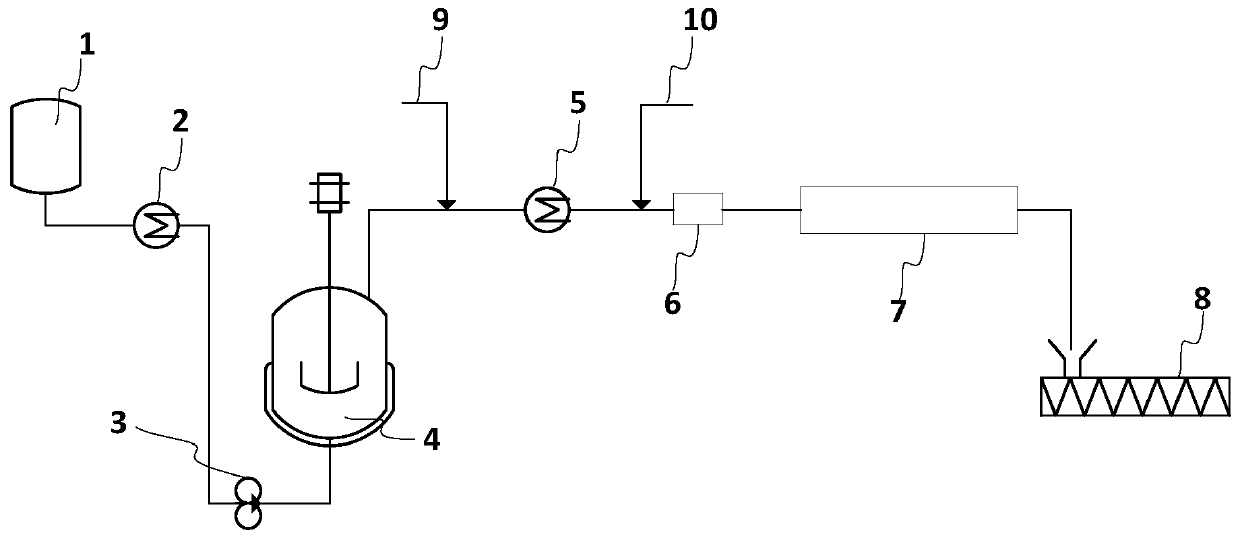

[0062] Add 75Kg styrene (SM), 25Kg acrylonitrile (AN) and 0.065Kg chain transfer agent tertiary dodecyl mercaptan into the 200L batching tank 1, mix well and cool to -20°C through the first heat exchanger 2.

[0063] Through the melt booster pump 3, the above raw material mixture is continuously transported at a feed rate of 10L / h to a fully mixed flow polymerization kettle 4 with a volume of 10L and good heat preservation. The feed temperature of the mixed liquid is controlled to maintain the temperature in the kettle at about 150°C, the average residence time of the material in the kettle is 1h, and the slurry A is obtained by overflowing and discharging from the top of the kettle. After testing, the monomer conversion rate of the first stage is 39%.

[0064] The overflowed slurry A is continuously transported to the rear stage, and N, N-dimethylformamide is continuously added to the pipeline for transporting the slurry A at a feed rate of 1 L / h through the monomer and solve...

Embodiment 2

[0067] Add 80Kg styrene, 20Kg acrylonitrile and 0.06Kg chain transfer agent tertiary dodecyl mercaptan into the 200L batching tank 1, mix well and cool to -25°C through the first heat exchanger 2.

[0068] Through the melt booster pump 3, the above raw material mixture is continuously transported at a feed rate of 6.6L / h to a fully mixed flow polymerization kettle 4 with a volume of 10L and good heat preservation. The feed temperature of the raw material mixture is controlled to maintain the temperature in the kettle at about 140°C. The average residence time of the material in the kettle is 1.5h, and the slurry A is obtained by overflowing and discharging from the top of the kettle. After testing, the monomer conversion rate of the first stage is 42%.

[0069] Continuously transport the overflowed slurry A to the subsequent stage, and continuously add N,N-dimethylformamide to the pipeline for transporting the slurry A at a feed rate of 0.66L / h through the monomer and solvent...

Embodiment 3

[0072] Add 80Kg styrene, 20Kg acrylonitrile and 0.06Kg chain transfer agent tert-dodecyl mercaptan into the 200L batching tank 1, mix well and cool to -10°C through the first heat exchanger 2.

[0073] Through the melt booster pump 3, the above raw material mixture is continuously transported at a feed rate of 12.5L / h to a fully mixed flow polymerization kettle 4 with a volume of 10L and good heat preservation. The feed temperature of the raw material mixture is controlled to maintain the temperature in the kettle at about 150°C. The average residence time of the material in the kettle is 0.8h, and the material is overflowed from the top of the kettle to obtain the slurry A. After testing, the monomer conversion rate of the first stage is 35%.

[0074] Continuously transport the overflowed slurry A to the subsequent stage, and continuously add N,N-dimethylformamide to the pipeline for transporting the slurry A at a feed rate of 1.26L / h through the monomer and solvent feed lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com