Preparation method of star-shaped polymer dispersant, and product and application thereof

A star-shaped polymer and dispersant technology, applied in the direction of pigment slurry, etc., can solve the problems of dispersant anchoring ability and steric hindrance, uncontrollable relative molecular mass, poor dispersion stability of pigment particles, etc., to achieve relative molecular Narrow mass distribution, controllable relative molecular mass, and improved dispersion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

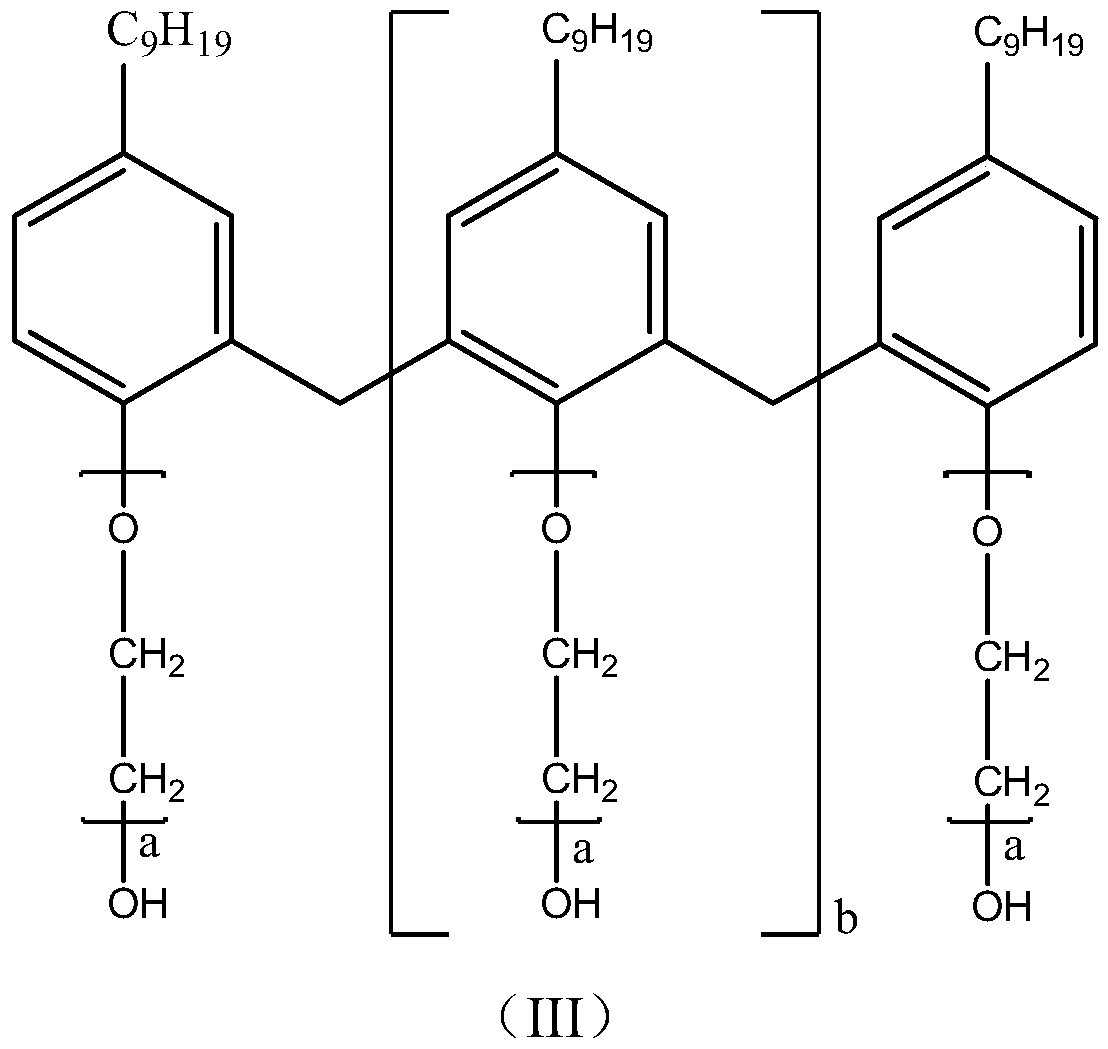

[0034] A preparation method of a star-shaped polymer dispersant, in parts by mass, comprising the steps of:

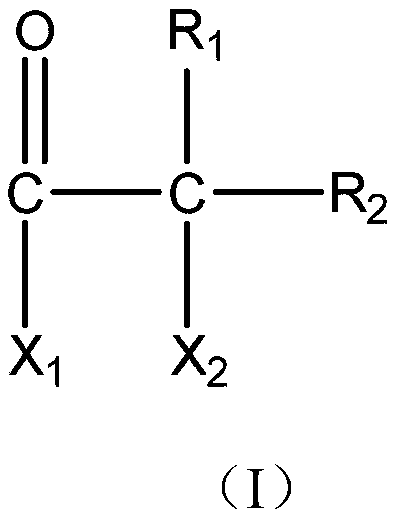

[0035] S1: Dissolving 136 parts by mass of pentaerythritol in a solvent of 800 to 1000 parts by mass, adding 500 to 800 parts by mass of an initiator and 300 to 500 parts by mass of triethylamine , react at a temperature of 0-30°C for 3-6h, remove the solvent to obtain the initiating monomer;

[0036] S2: Take 100 parts by mass of the initiating monomer prepared in step S1, and 2 to 5 parts by mass of catalyst and 5 to 10 parts by mass of ligand, and 300 to 500 parts by mass 80-120 parts of solvent, 80-120 parts of styrene, and 80-120 parts of maleic anhydride are respectively added to a reaction vessel filled with an inert gas, and reacted at a temperature of 60-90°C for 4- 8h, remove solvent and cool to room temperature, obtain star polymer;

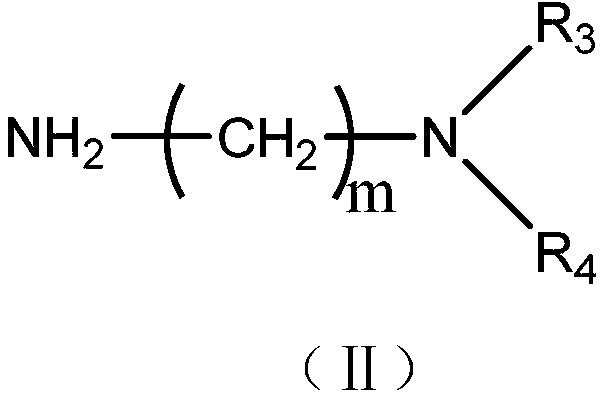

[0037] S3: Take the star polymer of 100 parts by mass obtained in step S2, add a solvent of 300 to 500 parts by mass and a ...

Embodiment 1

[0060] A preparation method of a star-shaped polymer dispersant, in parts by mass, comprising the steps of:

[0061] S1: Dissolve 136 parts by mass of pentaerythritol in 900 parts by mass of toluene, add 800 parts by mass of initiator A1 and 400 parts by mass of triethylamine, and react at a temperature of 10°C 5h, remove solvent and obtain initiation monomer;

[0062] S2: Take 100 parts by mass of the initiator monomer prepared in step S1, 3 parts by mass of CuBr and 6 parts by mass of 2,2'-bipyridine, and 400 parts by mass Toluene, 90 parts by mass of styrene, and 80 parts by mass of maleic anhydride were added to a reaction vessel filled with an inert gas, reacted at 70°C for 7 hours, removed the solvent and cooled to room temperature to obtain star polymer;

[0063] S3: Take 100 parts by mass of the star-shaped polymer prepared in step S2, add 400 parts by mass of toluene and 40 parts by mass of graft modifier B1 and react at a temperature of 95°C for 5 hours , and then...

Embodiment 2

[0065] A preparation method of a star-shaped polymer dispersant, in parts by mass, comprising the steps of:

[0066] S1: Dissolve 136 parts by mass of pentaerythritol in 800 parts by mass of N,N-dimethylformamide, add 500 parts by mass of initiator A2 and 300 parts by mass of Triethylamine was reacted at 0°C for 6h, and the solvent was removed to obtain the initiating monomer;

[0067] S2: get the initiation monomer that the mass fraction that step S1 makes is 100 parts, and the mass fraction is 2 parts of CuCl and the mass fraction is 10 mass fractions of pentamethyldiethylenetriamine, mass fraction is Add 500 parts of N,N-dimethylformamide, 100 parts by mass of styrene, and 120 parts by mass of maleic anhydride into a reaction vessel filled with an inert gas, and react at a temperature of 90°C 4h, remove solvent and cool to room temperature, obtain star polymer;

[0068] S3: Take 100 parts by mass of the star-shaped polymer prepared in step S2, add 500 parts by mass of N,N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com