Building solid waste recycled aggregate dry-mixed plastering mortar and preparation method thereof

A technology of recycled aggregate and plastering mortar, which is applied in the field of building materials, can solve problems such as high quality hidden dangers, poor impermeability and water retention, and achieve the effects of saving resources, meeting quality requirements, and good crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

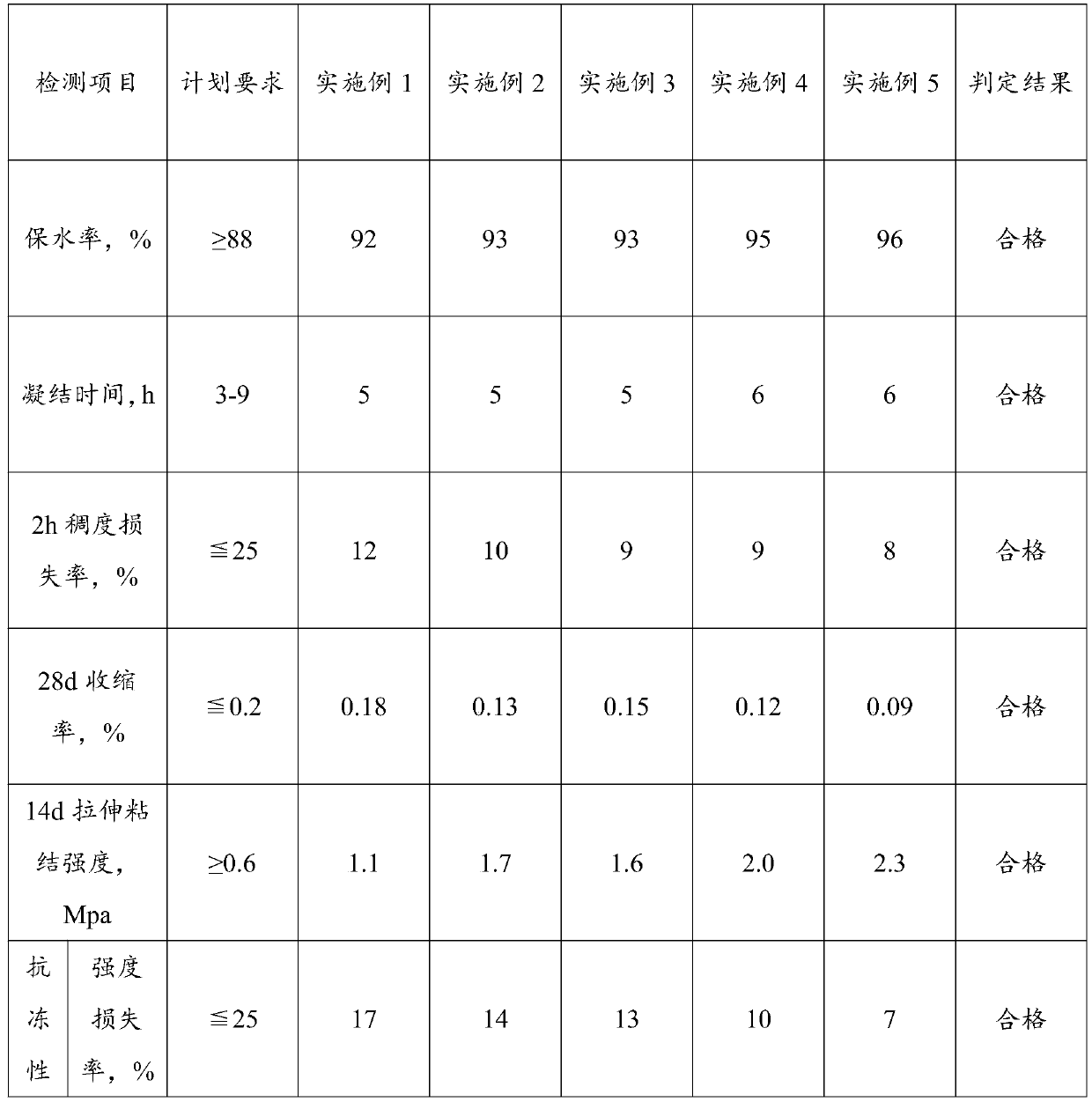

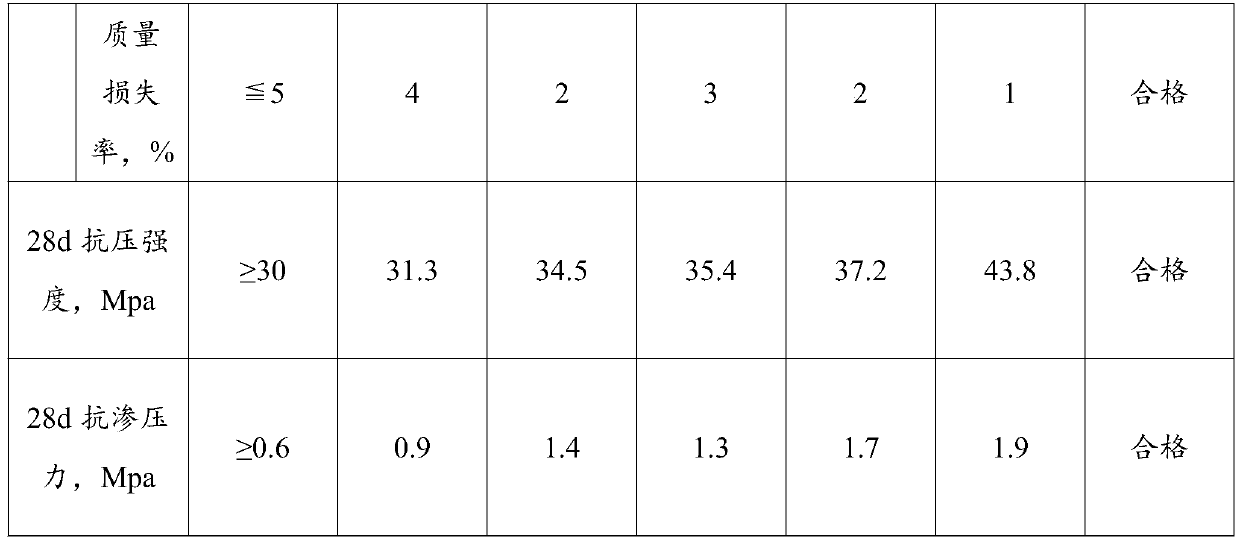

Examples

preparation example Construction

[0020] In an embodiment of the present invention, the preparation method of the construction solid waste recycled aggregate dry-mixed plastering mortar includes:

[0021] Take the raw material according to the following parts by weight:

[0022] 25-35 parts of medium sand, 15-27 parts of cement, 20-40 parts of construction solid waste sand, 8-13 parts of PP fiber, 0.5-1.5 parts of triethanolamine, 3-6 parts of ethylene glycol, 3 parts of lignin calcium sulfate ~6 parts, latex powder 4~8 parts;

[0023] Add the PP fiber, lignin calcium sulfate and latex powder to the construction solid waste sand making, put it into a reaction kettle and stir it at 120-150°C for 1-3 hours to obtain a mixture A;

[0024] Grinding the cement, adding the triethanolamine and ethylene glycol during the grinding process, and grinding for 0.5-1 hour to obtain a mixture B;

[0025] The mixture A, mixture B and the medium sand were initially stirred and mixed for 10-20 minutes, then stirred at a tempe...

Embodiment 1

[0034] A construction solid waste regenerated aggregate dry-mixed plastering mortar, comprising the following components in parts by weight:

[0035] 25.5 parts of medium sand; 16.4 parts of cement; 20 parts of construction solid waste sand; 8 parts of PP fiber; 0.6 parts of triethanolamine; 3.5 parts of ethylene glycol; 3.5 parts of lignin calcium sulfate; 4 parts of latex powder.

[0036] Weigh the raw materials according to the above weight percentage; add the PP fiber, lignin calcium sulfate and latex powder to the construction solid waste sand making, put them into the reaction kettle and stir at 120°C for 1 hour to obtain the mixture A; The cement is ground, and the triethanolamine and ethylene glycol are added during the grinding process, and the mixture B is obtained by grinding for 0.5 h; the mixture A, the mixture B and the medium sand are initially stirred and mixed for 10 minutes, and then mixed at 70 Stirring at 100°C for 10 minutes, stirring at 150°C for 20 minut...

Embodiment 2

[0038] A construction solid waste regenerated aggregate dry-mixed plastering mortar, comprising the following components in parts by weight:

[0039] 34.8 parts of medium sand; 26.4 parts of cement; 39.5 parts of construction solid waste sand; 13 parts of PP fiber; 1.5 parts of triethanolamine; 6 parts of ethylene glycol; 6 parts of lignin calcium sulfate; 8 parts of latex powder.

[0040] Weigh the raw materials according to the above weight percentage; add the PP fiber, lignin calcium sulfate and latex powder to the construction solid waste sand making, put them into the reaction kettle and stir at 150°C for 3 hours to obtain the mixture A; The cement is ground, and the triethanolamine and ethylene glycol are added during the grinding process, and the mixture B is obtained by grinding for 1 hour; the mixture A, the mixture B and the medium sand are initially stirred and mixed for 20 minutes, and then mixed at 90°C Stirring treatment at low temperature for 20 minutes, stirrin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com