Cold rolling method of TC4 titanium alloy wires

A titanium alloy wire and annealing technology, which is applied in the direction of metal rolling, heat treatment equipment, furnaces, etc., can solve the problems of decreased elongation, small cold drawing deformation, elongation after breaking, and reduced area shrinkage yield strength. Achieve the effect of production effect and product quality stability improvement, good consistency of mechanical properties and dimensional accuracy, performance and stability satisfaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

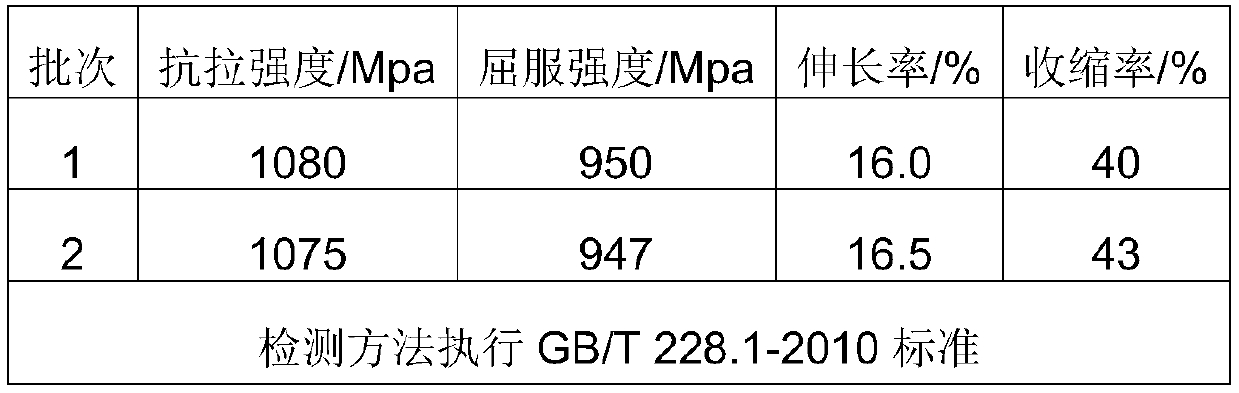

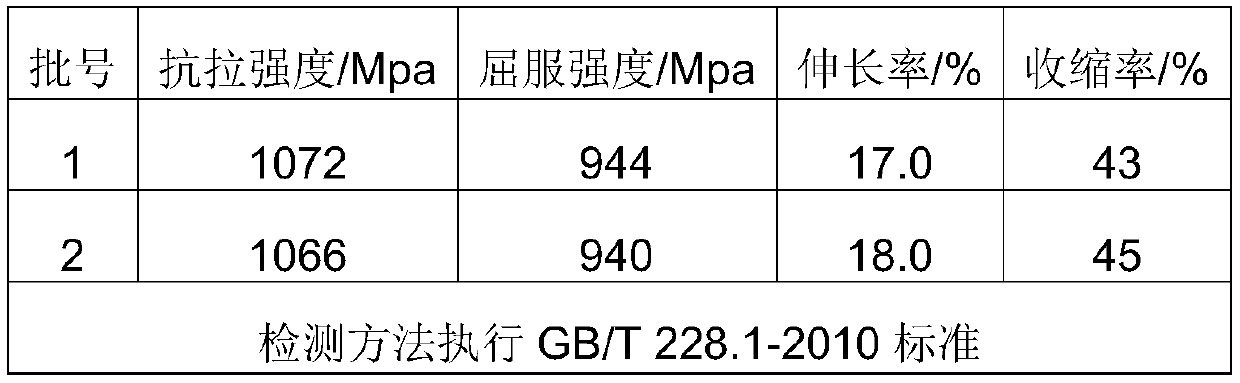

[0038] Example 1: Preparation of Φ3.0mm TC4 titanium alloy wire by cold rolling

[0039] Billet grade: TC4, state: coil wire, specification: Φ9.8mm. The cold rolling adopts a 4-station tandem continuous cold rolling mill, and the rolling pass adopts a round-polygonal-round structural design.

[0040] Pickling, repairing, and thoroughly grinding the cracks and sticky pits on the surface of the billet.

[0041] Atmospheric furnace annealing, holding at 780°C for 60min.

[0042] In the first pass of cold rolling, the deformation rate is 24.6%.

[0043] In the second pass of cold rolling, the deformation rate is 18.6%; annealed in an atmospheric furnace, and kept at 750°C for 60 minutes; inspect for defects.

[0044] In the third pass of cold rolling, the deformation rate is 20.1%.

[0045] The fourth pass is cold rolling, with a deformation rate of 17.7%; annealing in an atmospheric furnace, holding at 730°C for 45 minutes; checking for defects.

[0046] The fifth pass is co...

Embodiment 2

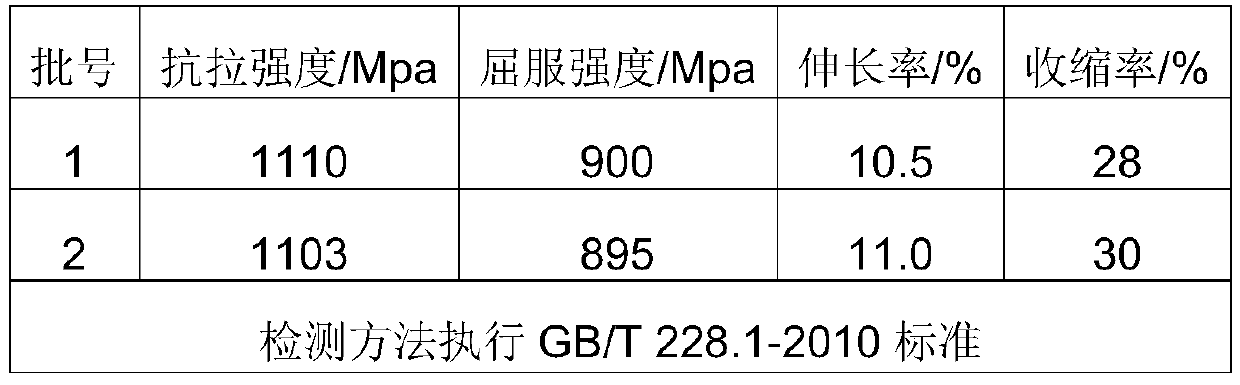

[0069] Embodiment 2: Preparation of Φ4.0mmTC4 titanium alloy wire by cold rolling

[0070] Billet grade: TC4, state: coiled wire, specification: Φ9.8mm; cold rolling adopts 4-station tandem continuous cold rolling mill, and the rolling pass adopts a round-polygonal-round structural design.

[0071] Pickling, repairing, and thoroughly grinding the cracks and sticky pits on the surface of the billet.

[0072] Atmospheric furnace annealing, holding at 780°C for 60min.

[0073] In the first pass of cold rolling, the deformation rate is 25.0%.

[0074] The second pass is cold rolling, with a deformation rate of 17.9%; annealing in an atmospheric furnace, holding at 750°C for 60 minutes; checking for defects.

[0075] In the third pass of cold rolling, the deformation rate is 21.1%.

[0076] The fourth pass of cold rolling has a deformation rate of 17.1%. Atmospheric furnace annealing, heat preservation at 730°C for 45 minutes; check for defects.

[0077] The fifth pass is cold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com