A kind of magnetic polymer nano adsorption material lm-mp and its preparation method and application

A nano-adsorption material, LM-MP technology, applied in alkali metal compounds, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve the problems of difficult recovery, small adsorption capacity, difficult regeneration, etc., and achieve easy modification and easy Modification, not easy to secondary pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

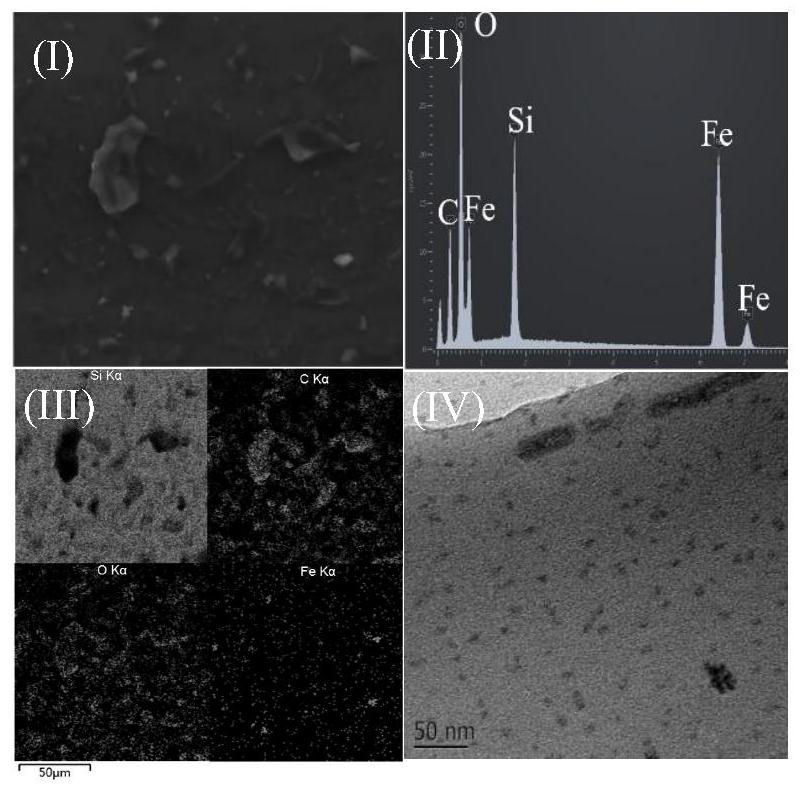

[0030] Embodiment 1: a kind of preparation method of magnetic polymer nano adsorption material LM-MP comprises the following steps:

[0031] 1) Preparation of polymer material LM-P:

[0032] First, add 2.45g LM and 2.5mL triethylamine to 10mL DMSO in turn, stir rapidly until the solution is clear, add 5.64g PDA, and react at room temperature for 24h to obtain a block-like gel-state product. After the gel-state product is ground Acetone precipitation was carried out, and the precipitate obtained by suction filtration was washed and filtered with 300mL ultrapure water and freeze-dried to obtain 5.6g of white powder, the polymer material LM-P;

[0033] 2) Preparation of magnetic nanoparticles MNP@LM-P:

[0034] 1.0g FeCl 3 ·6H 2 O, 0.45g FeCl 2 4H 2 0 and 0.9g of LM-P obtained in step 1) were placed in a three-necked flask, 200mL of ultrapure water was added, stirred and heated to 80°C under nitrogen protection, and concentrated ammonia water was added dropwise after 5min to...

Embodiment 2

[0042] Example 2: Adsorption of cationic dyes by LM-MP

[0043] 1) Effect of pH on adsorption performance

[0044] Measure the absorbance of LM-MP before and after dye adsorption under pure water and different pH (2-10) conditions, and explore the effect of pH on the adsorption performance of LM-MP, such as Image 6 .

[0045] from Image 6 It can be seen that under the conditions of strong acid and strong alkali, the adsorption performance of LM-MP is relatively weakened. Under the conditions of , 7, 8, 9 and secondary water, the adsorption performance is better, so it can be concluded that the adsorbent has a wide range of applications, and the follow-up experiments are all carried out under the condition of secondary water.

[0046] 2) Effect of ionic strength on adsorption performance

[0047] Measure the absorbance of LM-MP before and after dye adsorption in NaCl solution at different concentrations (0, 0.01, 0.1, 0.5, 1, 1.5, 2mol / L), and explore the effect of ionic ...

Embodiment 3

[0063] Embodiment 3: Desorption and reuse experiment

[0064] The complex uses absolute ethanol as the eluent, ultrasonically oscillates for 10 minutes, then magnetically separates, then washes three times with secondary water and absolute ethanol, and vacuum-dries at 40°C to obtain desorbed magnetic polymer nano-adsorption materials. Recycle. This cycle was repeated 6 times, and the adsorption amount of the dye by LM-MP in each cycle was calculated, as Figure 13 .

[0065] It can be seen from Figure 13 that after LM-MP is reused 6 times, the adsorption efficiency is still maintained, and some dyes have increased, indicating that LM-MP is a reusable dye adsorption material. It shows that the complex has a good application prospect in environmental water purification.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturation magnetization | aaaaa | aaaaa |

| Total pore volume | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com