Preparation method of nickel oxide loaded modified activated carbon fiber adsorbent

A technology of activated carbon fiber and nickel oxide, applied in chemical instruments and methods, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve the problem that the hydrogen storage capacity does not reach the ideal hydrogen adsorption capacity, and achieve good hydrogen adsorption capacity , uniform loading, safe and easy adsorption conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1. Example 1 (the 11th group of experimental data)

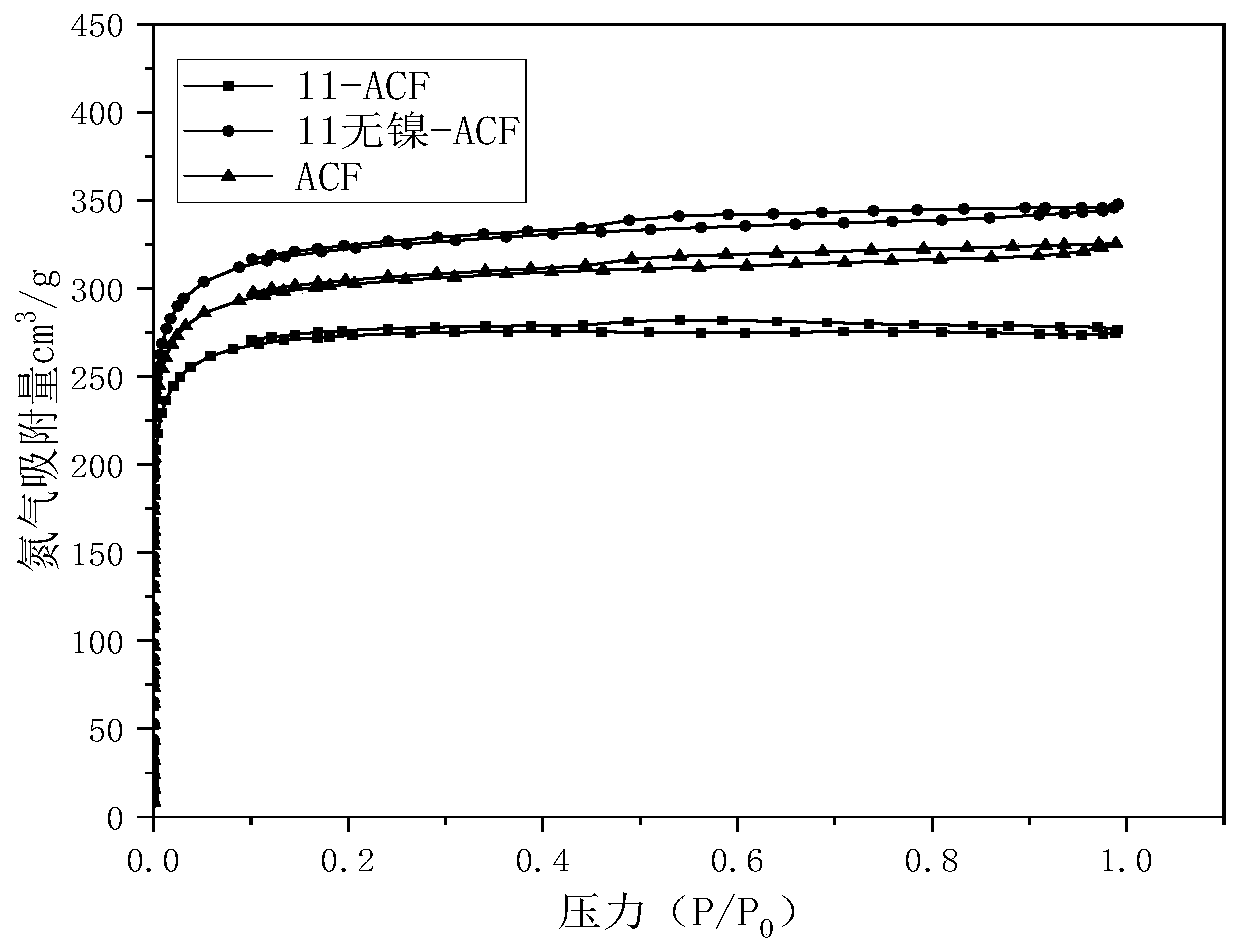

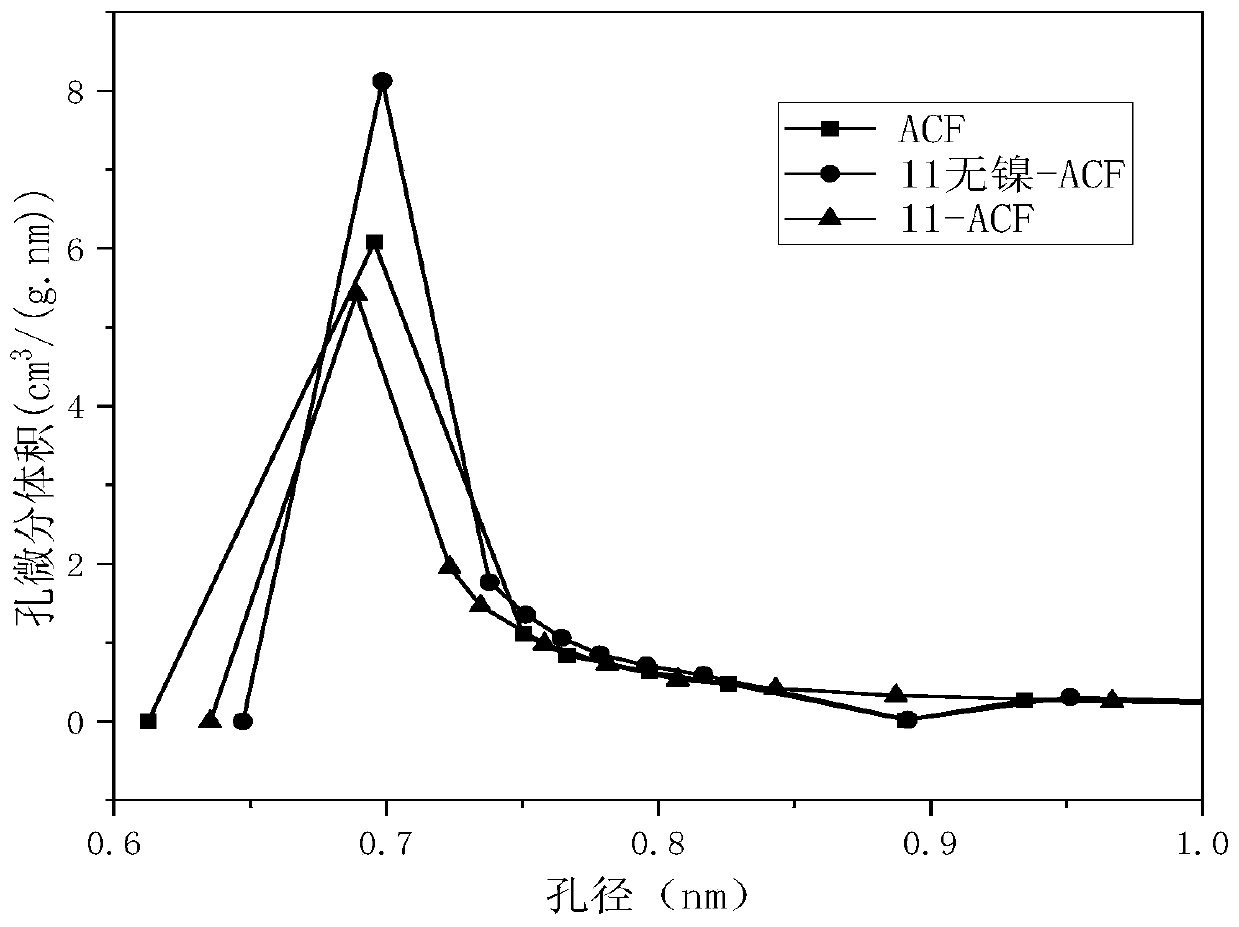

[0033] Weigh 0.6g of cleaned activated carbon fiber, place it in 80ml mass fraction of 0.5wt.% nickel nitrate solution for impregnation, ultrasonically oscillate for 30 minutes, place it in a water bath and stir for 6 hours, wash until neutral, and place it in an oven at 80°C overnight , take it out and set aside. The impregnated and dried activated carbon fibers were placed in a tube furnace and raised to 600 °C at a rate of 6 °C / min under nitrogen, and then returned to room temperature at the same rate after maintaining for 60 min to prepare activated carbon fibers loaded with nickel oxide. , nitrogen adsorption and desorption of the adsorbent, pore size distribution, SEM, XPS, hydrogen storage performance, such as figure 1 , 2 , 4, 7, and 8.

Embodiment 2

[0035] Weigh 0.6g of cleaned activated carbon fiber, place it in 80ml mass fraction of 0.5wt.% samarium nitrate solution for impregnation, ultrasonically oscillate for 30 minutes, place it in a water bath and stir for 6 hours, wash until neutral, place it in an oven at 80°C overnight , take it out and set aside. The impregnated and dried activated carbon fibers were placed in a tube furnace and raised to 600 °C at a rate of 6 °C / min under nitrogen gas, and then returned to room temperature at the same rate after maintaining for 60 min to prepare activated carbon fibers loaded with samarium oxide .

Embodiment 3

[0037] Weigh 0.6g of cleaned activated carbon fiber, place it in 80ml mass fraction of 0.5wt.% copper nitrate solution for immersion, ultrasonically oscillate for 30 minutes, place it in a water bath and stir for 6 hours, wash until neutral, and place it in an oven at 80°C overnight , take it out and set aside. The impregnated and dried activated carbon fibers were placed in a tube furnace and raised to 600 °C at a rate of 6 °C / min under nitrogen gas, and then returned to room temperature at the same rate after maintaining for 60 min to prepare activated carbon fibers loaded with samarium oxide .

[0038] 4. Embodiment 4

[0039] Weigh 0.6g of cleaned activated carbon fiber, place it in 80ml mass fraction of 0.5wt.% nickel nitrate solution for impregnation, ultrasonically oscillate for 30 minutes, place it in a water bath and stir for 6 hours, wash until neutral, and place it in an oven at 80°C overnight , take it out and set aside. Activated carbon fibers loaded with nicke...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com