A3 axle steel, and A3 axle and heat treatment process method thereof

A process method and axle steel technology, applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problems of poor overall performance, poor hardenability, low strength and toughness, etc., and achieve convenient and timely adjustment, manufacturing cost reduction, diffusion Ability-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] An A3 axle steel, comprising the following components in mass percentage: 0.34-0.37% carbon, 0.25-0.40% silicon, 1.40-1.50% manganese, phosphorus ≤ 0.020%, sulfur ≤ 0.015%, chromium 0.20-0.30%, nickel 0.13~0.20%, copper ≤0.30%, molybdenum ≤0.40%, vanadium 0.035~0.045%, aluminum 0.015~0.040%, the rest is iron and unavoidable impurities; because EA4T axle steel is currently widely used in domestic and foreign subway cars and high-speed EMU, and the A3 axle steel described in the present invention appropriately increases the content of carbon and manganese in order to strengthen and increase the hardenability of the axle at the same time, because carbon is the most important strengthening element and one of the hardenability improving elements 1. Manganese is an effective element for deoxidation and desulfurization, and it is also an element that improves hardenability; at the same time, reduce the amount of alloy, use vanadium microalloying, and add an appropriate amount o...

Embodiment 2

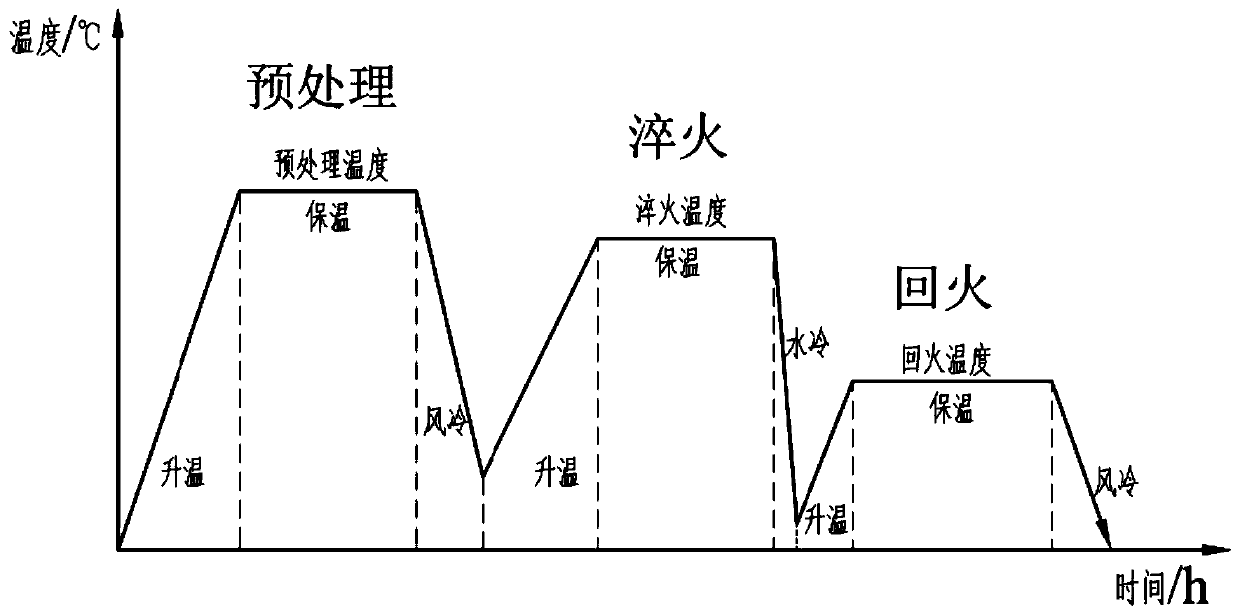

[0051] Such as figure 1 , figure 2 with image 3 As shown, it is basically the same as in Example 1. Specifically, in this example, the cross-sectional size of the axle used is 250mm*250mm. The difference from Example 1 is that the specific mass percentages of A3 axle steel are as follows: carbon 0.355%, silicon 0.325% %, manganese 1.45%, phosphorus 0.020%, sulfur 0.015%, chromium 0.25%, nickel 0.165%, copper 0.30%, molybdenum 0.40%, vanadium 0.04%, aluminum 0.0275%, the rest is iron with unavoidable impurity content determined by empirical formula Calculate the material Ac1 is about 720°C, Ac3 is about 810°C, Ms is about 310°C, and CE is about 0.67%; and the ring heating furnace is used for the forging heating and pretreatment process, the quenching furnace is used for the quenching process, and the tempering furnace is used for the tempering process. The pretreatment furnace, quenching furnace and tempering furnace are all heated by resistance band, and the furnace is equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com