Recovery device and method for heat and moisture of blast furnace granulating slag steam

A blast furnace water slag and recovery device technology, applied in the direction of recycling technology, process efficiency improvement, etc., can solve the problems of easily corroded equipment, heat and water recovery difficulties of water slag steam, etc., so as to reduce the corrosion of equipment and reduce harmful effects. Substance and visible vapour emissions, effect of reducing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

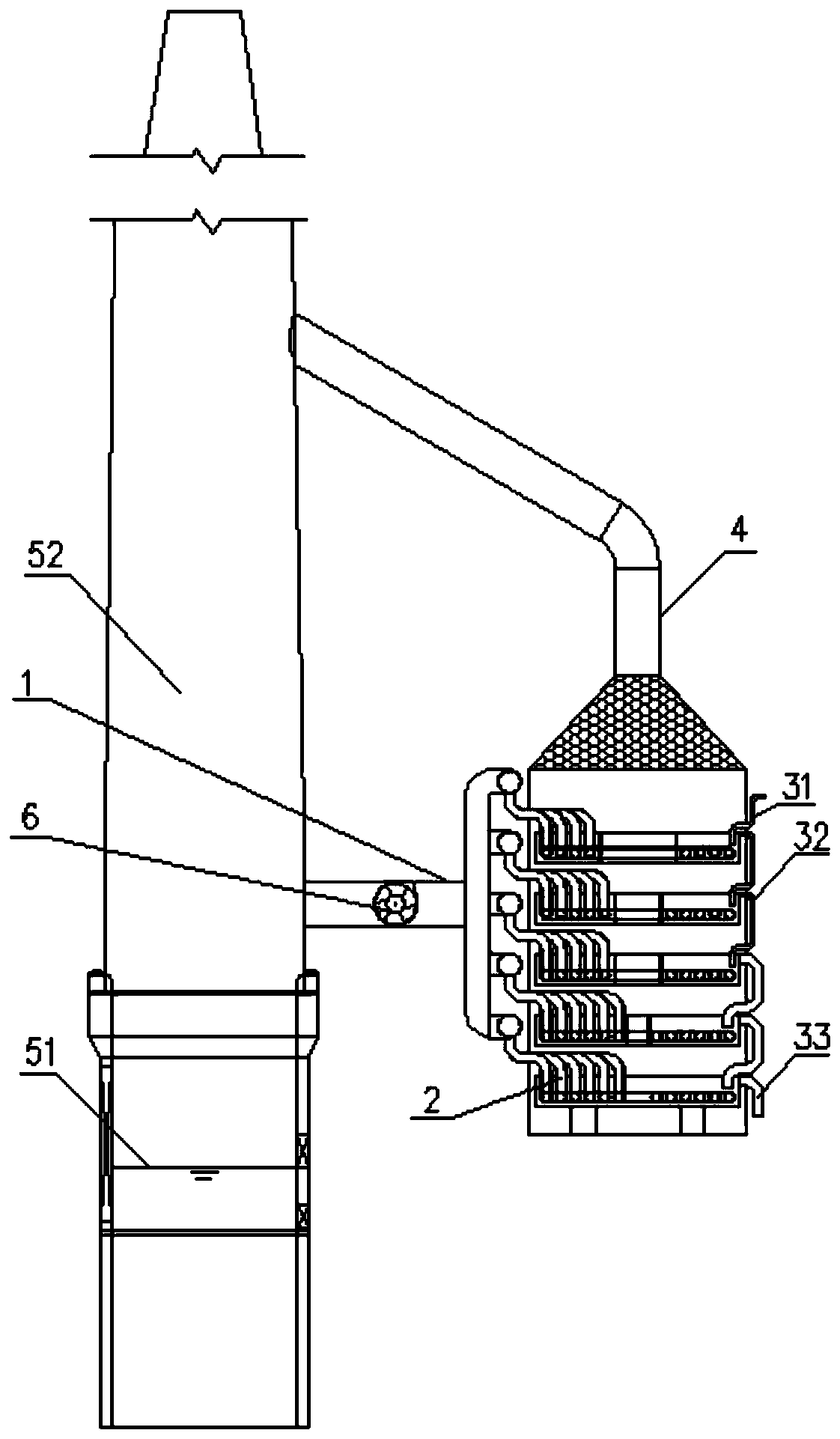

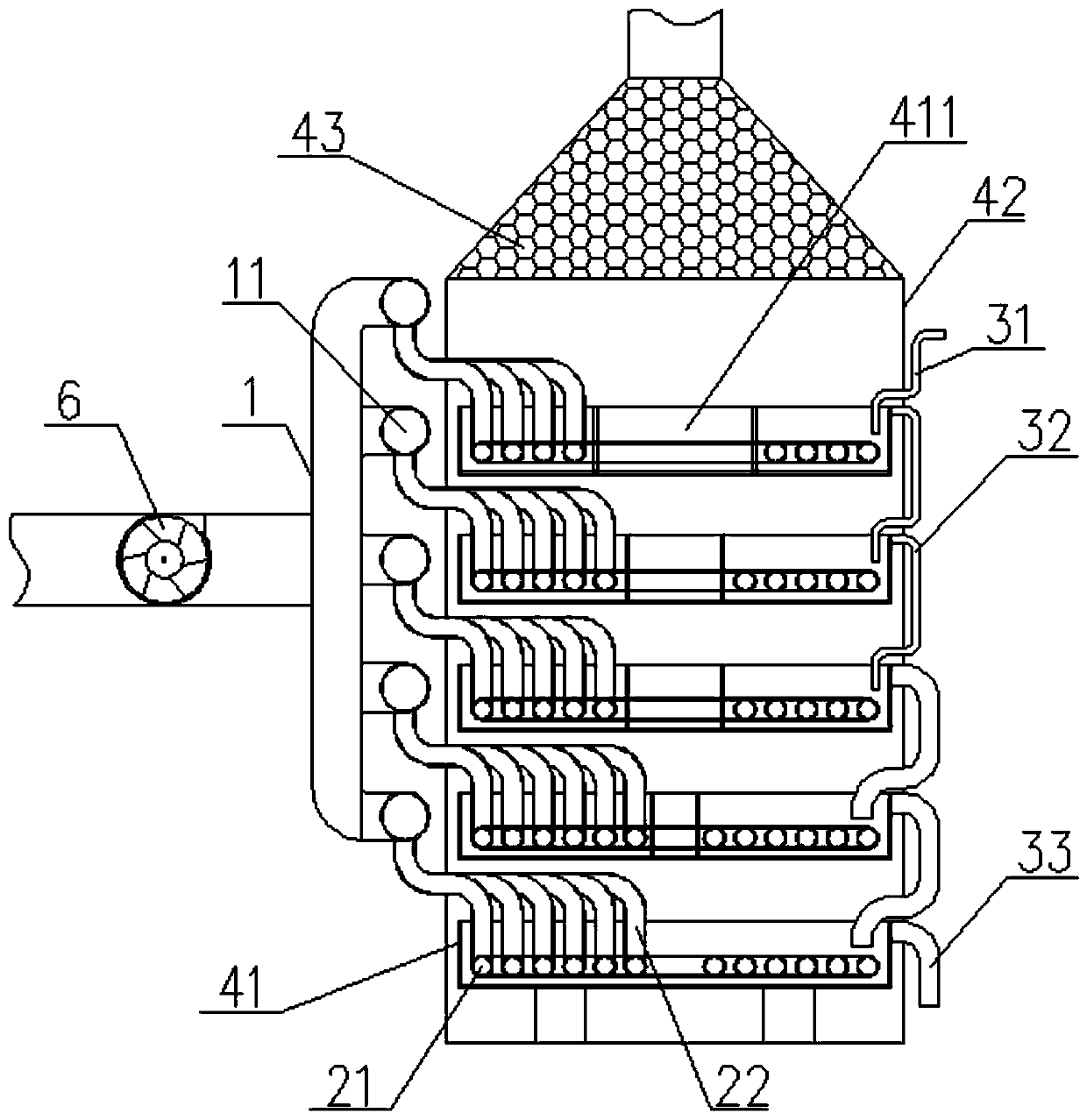

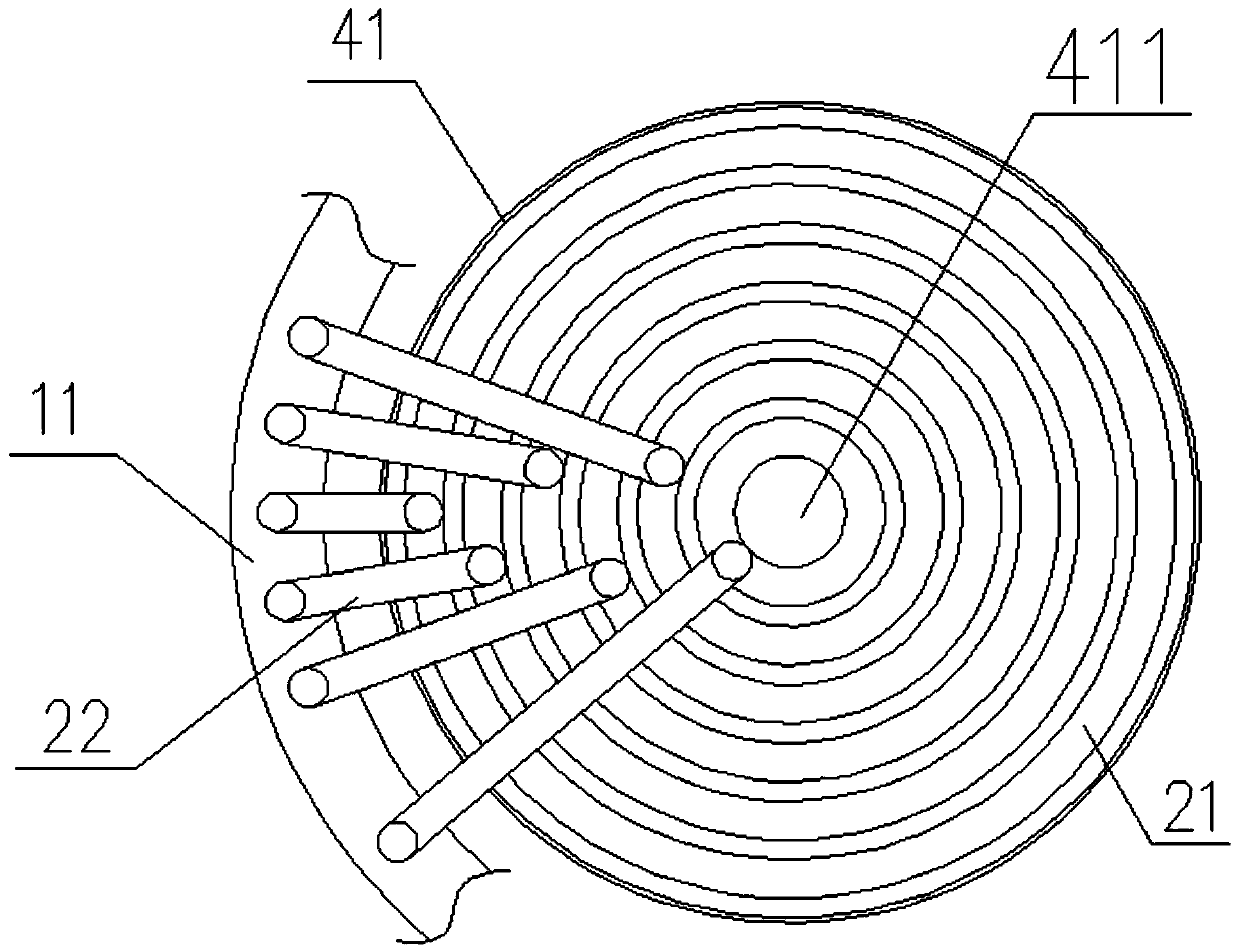

Embodiment 1

[0051] The first blast furnace has a daily output of 3000t / d red slag, 12 slag discharges per day, an average output of about 250t / h, a temperature of about 1450°C, a specific heat capacity of red slag of 1.2KJ / kg K, a granulation water of 1900t / h, an inlet water temperature of 40°C, and a granulation The final water temperature is 90°C, and the water slag temperature is 90°C. Calculating the steam generation of water slag, the steam temperature is about 120°C, the heat enthalpy is 2700kJ / kg, the flow rate is about 3.33t / h, and the volume flow rate is about 5831.9m 3 / h, equivalent to about 4051.2Nm in the standard state 3 / h, the total heat carried by the steam is about 9×10 6 kJ / h. Since the water slag granulation tower 51 is not a closed device, a large amount of air is involved under the natural draft of the high-altitude chimney. The injection device 6 adopts a steam injection fan, and the flow rate of the steam injection fan is set to 7000m 3 / h, the boost pressure i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com