Polyimide material as well as preparation method and application thereof

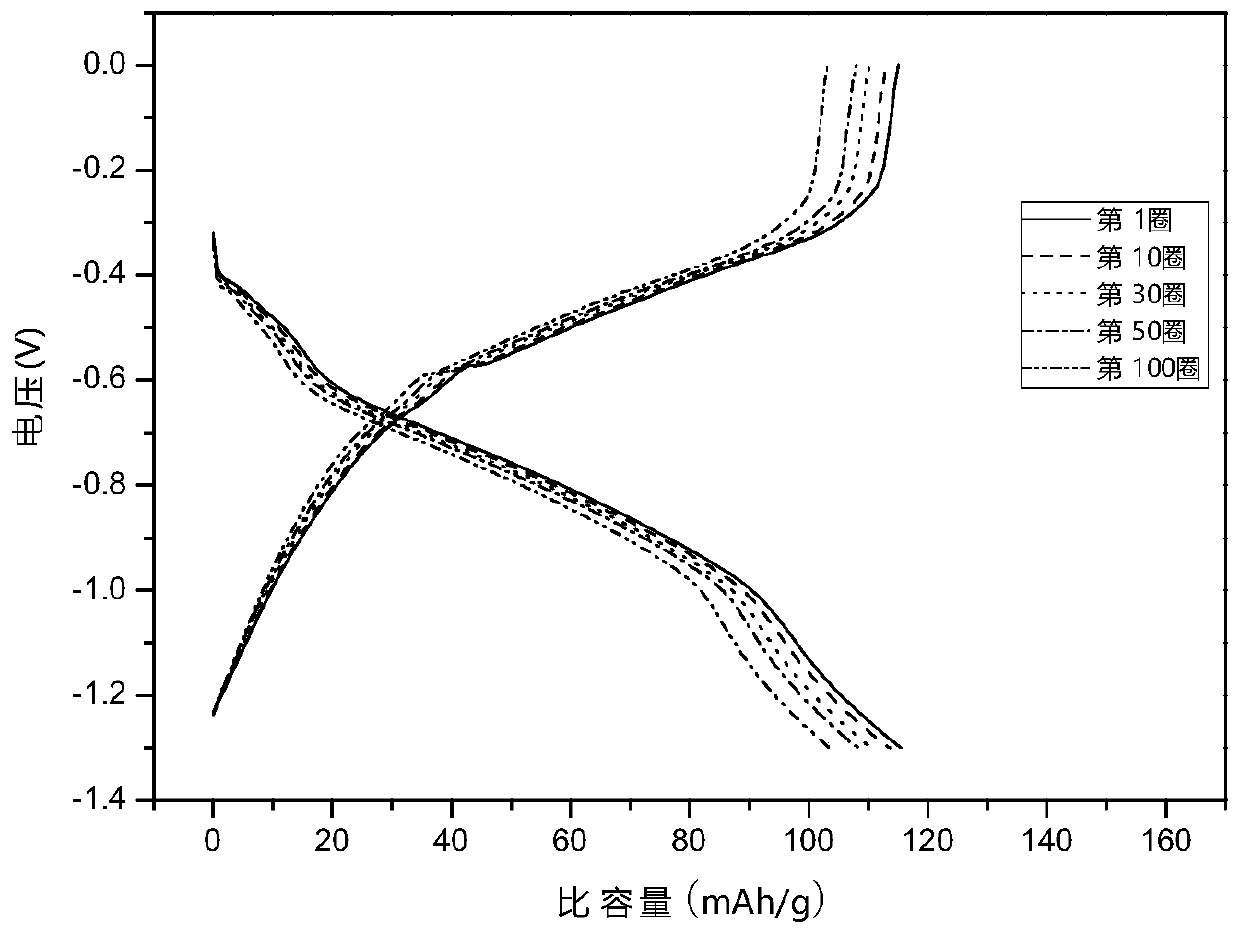

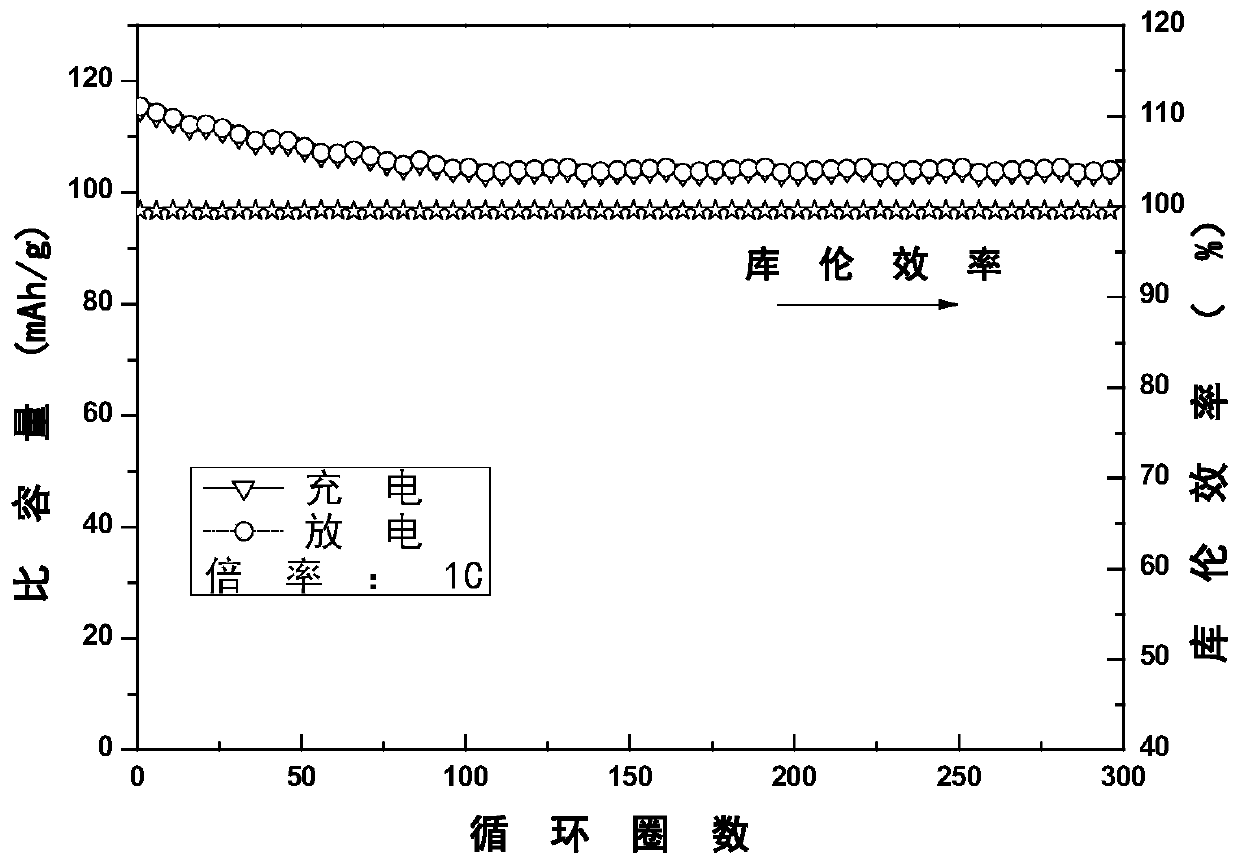

A polyimide and reaction technology, applied in the field of polymer preparation, can solve the problems of low negative electrode electrochemical capacity, unstable oxygen and hydrogen-oxygen, and low battery cycle life, and achieve the effect of high specific capacity and stable cycle times.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0104] The preparation of embodiment 1 polyimide

[0105] Step A: Using N,N-dimethylformamide (DMF) as a solvent, add 1,4,5,8-naphthalene tetracarboxylic dianhydride (NTCDA) and urea at a molar ratio of 1:1 to obtain 1,4, The total concentration of 5,8-naphthalene tetracarboxylic dianhydride and urea is 50g / 500ml. The reaction vessel is a glass flask. Under the protection of argon, the reactant is kept at 90°C for 2 hours, and then heated to 150°C. And react at this temperature for 6 hours.

[0106] Step B: Collect the resultant and dry it under vacuum at 200° C. to obtain a dry powder, which is designated as polyimide sample 1.

Embodiment 2

[0108] It is basically the same as Example 1, the only difference is that the reactant is directly heated to 150° C., and reacted at this temperature for 6 hours, and the obtained product is recorded as polyimide sample 2.

Embodiment 3

[0110] It is basically the same as in Example 1, except that 1,4,5,8-naphthalene tetracarboxylic dianhydride is replaced by pyromellitic dianhydride, and the obtained product is designated as polyimide sample 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com