A novel low free TDI polyurethane curing agent containing fluorocarbon chain and preparation method thereof

A polyurethane and carbon chain technology, applied in the preparation of amino hydroxyl compounds, chemical instruments and methods, polyurea/polyurethane coatings, etc., can solve the poor performance of TDI-TMP addition curing agent, limited coating construction conditions, two-component Chain extender modification and other issues, to achieve the effect of reducing reaction curing time, improving acid and alkali chemical corrosion resistance, and shortening reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

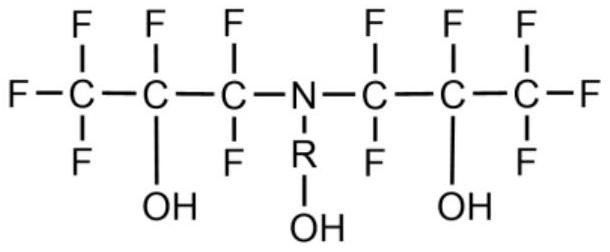

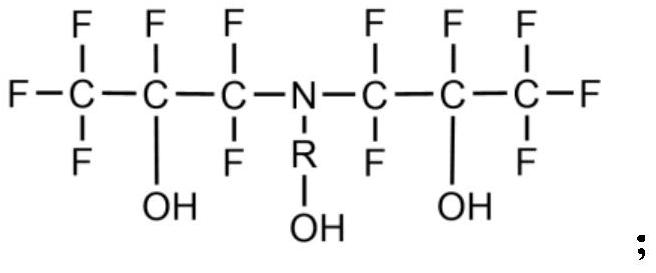

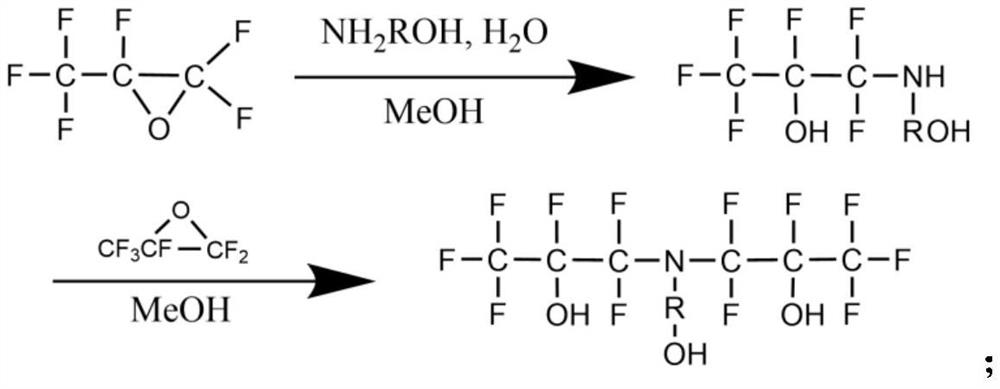

[0048] In the reaction kettle, according to the weight ratio of the formula, put 100g of methanol, 104g of perfluoropropylene oxide and 158g of aminomethanol into the kettle, start stirring (175rpm) and reflux and heat up to 45°C to start the reaction, and react for 6h Then stop the reaction and transfer to a rotary evaporator for distillation under reduced pressure at 60°C / -0.1MPa. After the methanol and aminomethanol are completely evaporated, transfer the initial product to the reaction kettle and add 125g perfluoropropylene oxide and 50g Methanol, start stirring (175rpm) and heat up to 65°C to continue the reaction. After 4 hours of reaction, continue to transfer to a rotary evaporator and distill at 60°C / -0.1MPa under reduced pressure, recrystallize and purify with chloroform, and finally obtain 196g of N, N-bis(2-hydroxy-perfluoropropyl)methanol adduct. Put it into the reaction kettle, add 121g of ethyl acetate and 0.8g of tris(2,4-di-tert-butylphenyl)phosphite, start st...

Embodiment 2

[0052]In the reaction kettle, according to the weight ratio of the formula, put 105g methanol, 99g perfluoropropylene oxide and 147g aminomethanol into the kettle respectively, start stirring (165rpm) and reflux and heat up to 40°C to start the reaction, and react for 5h Then stop the reaction and transfer to a rotary evaporator for distillation under reduced pressure at 60°C / -0.1MPa. After the methanol and aminomethanol are completely evaporated, transfer the initial product to the reaction kettle and add 115g perfluoropropylene oxide and 45g Methanol, start stirring (165rpm) and heat up to 65°C to continue the reaction. After 5 hours of reaction, continue to transfer to a rotary evaporator and distill under reduced pressure at 60°C / -0.1MPa, recrystallize and purify with chloroform, and finally obtain 186g of N, N-bis(2-hydroxy-perfluoropropyl)methanol adduct. Put it into the reaction kettle, add 112g of ethyl acetate and 0.6g of N,N-bis-(3-(3,5-di-tert-butyl-4-hydroxyphenyl)...

Embodiment 3

[0056] In the reaction kettle, according to the weight ratio of the formula, put 140g methanol, 114g perfluoropropylene oxide and 179g ethanolamine into the kettle respectively, start stirring (185rpm) and reflux and heat up to 50°C to start the reaction. After 7 hours of reaction Stop the reaction and transfer to a rotary evaporator for distillation under reduced pressure at 60°C / -0.1MPa. After methanol and aminomethanol are completely evaporated, transfer the initial product to a reaction kettle and add 136g of perfluoropropylene oxide and 68g of methanol , start stirring (185rpm) and heat up to 70°C to continue the reaction. After 6 hours of reaction, continue to transfer to a rotary evaporator and distill under reduced pressure at 60°C / -0.1MPa, recrystallize and purify with chloroform, and finally obtain 228g of N,N - Bis(2-hydroxy-perfluoropropyl)ethanol adduct. Put it into the reaction kettle and add 144g of butyl acetate and 1g of tetrakis[β-(3,5-di-tert-butyl-4-hydroxy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com