Electrostatic spinning synthesis method of In2O3 core-shell nanobelt structure

A technology of electrospinning and synthesis method is applied in the field of electrospinning synthesis of In2O3 core-shell nanobelt structure to achieve the effect of improving gas-sensing properties and improving viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1.1 First, configure a mixed solvent of 1.0 mL of ethanol, 4.0 mL of DMF and 0.01 mL of ethylene glycol methyl ether, and mix 0.6016 g of indium nitrate hydrate (InN 3 o9 . wxya 2 O), 0.0014 g of 1,3,5-benzenetricarboxylic acid, 0.0010 g of hydroxylamine hydrochloride and 0.0010 g of acrylamide were added in sequence, and stirred evenly;

[0025] 1.2 Add 0.7 g of PVP to obtain a homogeneous precursor spinning solution;

[0026] 1.3 The above spinning solution was electrospun to obtain the precursor fiber. The spinning parameters were: positive voltage 18 KV, negative voltage 0.5 KV, receiving distance 18 cm, and syringe advancing speed 0.002 mm / s;

[0027] 1.4 Fold the precursor fiber and lay it flat in the ark, then raise the temperature from room temperature to 600 °C at a rate of 5 °C / min, keep it warm for 2 h, and the sample is cooled with the furnace to obtain In 2 o 3 Core-shell nanoribbon structure.

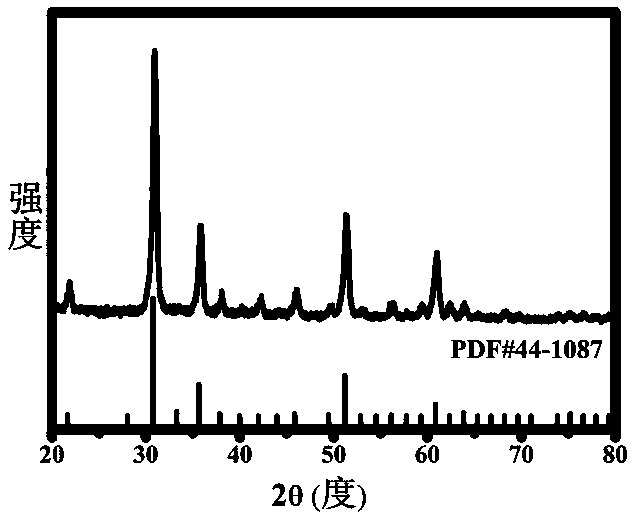

[0028] The XRD result of the product is as follows figur...

Embodiment 2

[0030] 2.1 First, configure a mixed solvent of 1.5 mL of ethanol, 3.5 mL of DMF and 0.015 mL of ethylene glycol methyl ether, and mix 0.6317 g of InN 3 o 9 . wxya 2 O, 0.0012 g of 1,3,5-benzenetricarboxylic acid, 0.0010 g of hydroxylamine hydrochloride and 0.0017 g of acrylamide were added successively and stirred evenly;

[0031] 2.2 Add 0.7 g of PVP to obtain a homogeneous precursor spinning solution;

[0032] 2.3 The above spinning solution was electrospun to obtain precursor fibers. The spinning parameters were as follows: positive voltage 17 KV, negative voltage 0.5 KV, receiving distance 20 cm, and syringe advancing speed 0.001 mm / s;

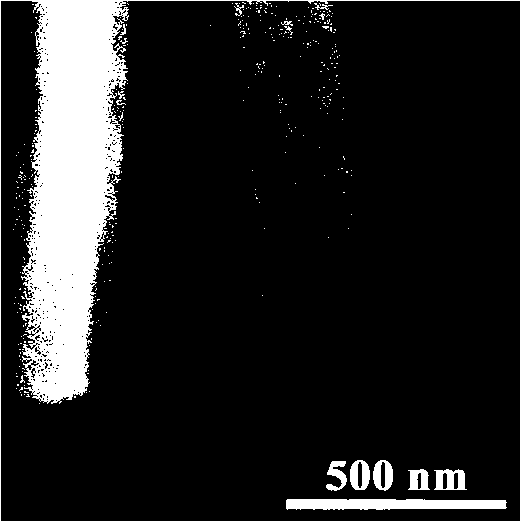

[0033] 2.4 Fold the precursor fiber and lay it flat in the ark, then raise the temperature from room temperature to 550 °C at a rate of 4 °C / min, keep it warm for 1.5 h, and the sample is cooled with the furnace to obtain In 2 o 3 Core-shell nanoribbon structure. In 2 o 3 The diameter of the core-shell nanoribbon structure is 400-5...

Embodiment 3

[0035] 3.1 First, configure a mixed solvent of 1.8 mL of ethanol, 4.3 mL of DMF and 0.02 mL of ethylene glycol methyl ether, and mix 0.5414 g of InN 3 o 9 . wxya 2 O, 0.0015 g of 1,3,5-benzenetricarboxylic acid, 0.0011 g of hydroxylamine hydrochloride and 0.0017 g of acrylamide were added successively and stirred evenly;

[0036] 3.2 Add 0.7037 g of PVP to obtain a homogeneous precursor spinning solution;

[0037] 3.3 The above spinning solution was electrospun to obtain the precursor fiber. The spinning parameters were as follows: positive voltage 18 KV, negative voltage 0.5 KV, receiving distance 19 cm, and syringe advancing speed 0.003 mm / s;

[0038] 3.4 Fold the precursor fiber and lay it flat in the ark, then raise the temperature from room temperature to 600°C at a rate of 5°C / min, and keep it warm for 2 hours. After the sample is cooled with the furnace, In 2 o 3 Core-shell nanoribbon structure. In 2 o 3 The diameter of the core-shell nanoribbon structure is 450...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com