Waterborne polyurethane-acrylate hybrid copolymer and preparation method thereof

A water-based polyurethane and acrylate technology, which is applied in the field of water-based polyurethane materials, can solve problems such as difficult control of crosslinking equivalent, unstable emulsion, and insignificant improvement in tolerance, and achieve stable production process without abnormalities, stable and controllable prepolymerization reaction, The effect of improving physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

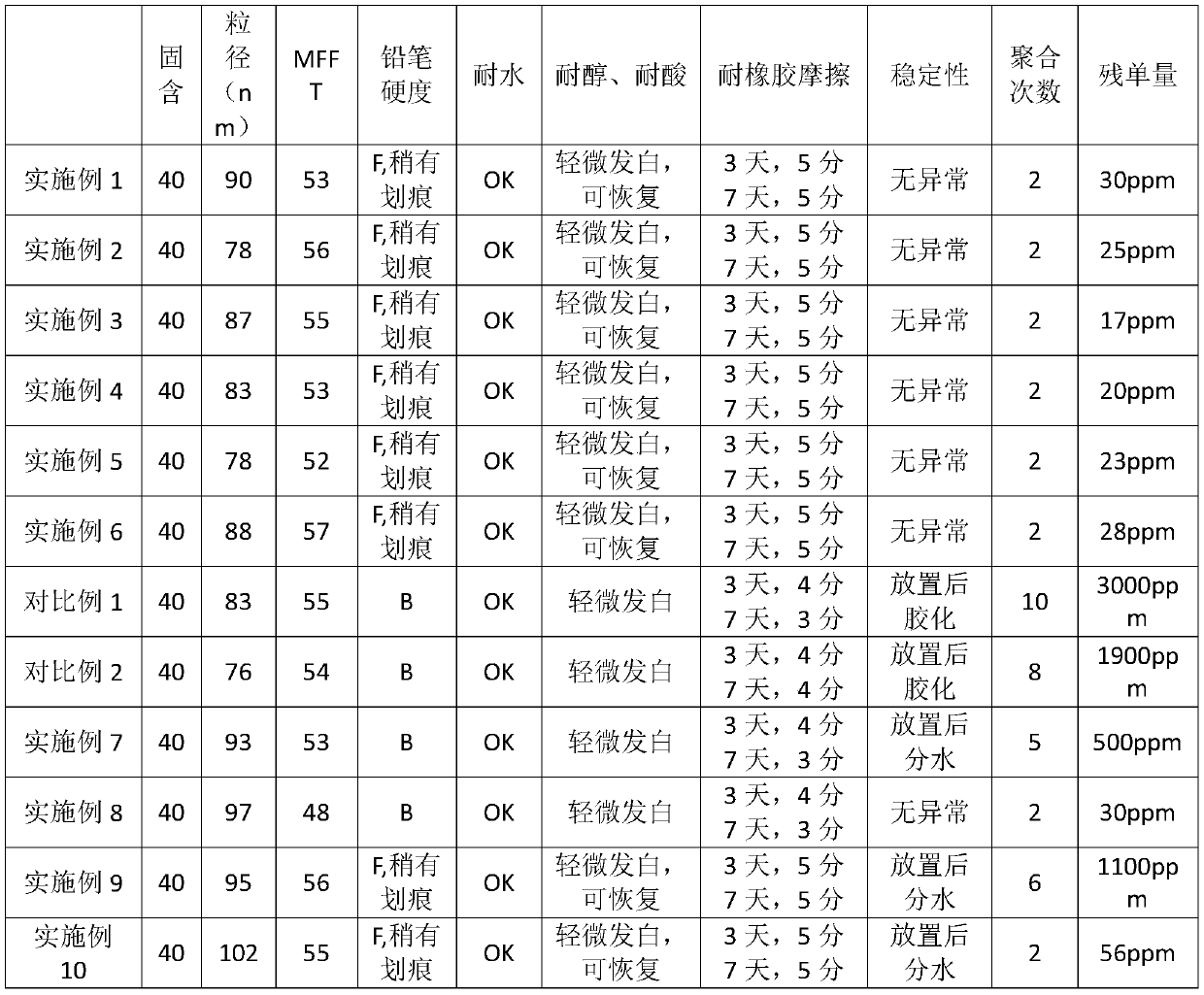

Examples

Embodiment 1

[0084] Add 80g WANNATE HMDI, 40g hydrogenated castor oil (iodine value 10-15), 40g PCL220N, and 0.05g organic bismuth catalyst, 24g acetone into a four-neck flask equipped with a thermometer, reflux condenser, and stirrer, heat up to 85°C and keep it warm for reaction , when the NCO value is constant at 10.36%, lower the temperature to 55°C, add 8g of dimethylolpropionic acid, 10g of 1,4-butanediol and 23g of acetone, and react at 75-80°C for 3-4 hours until the NCO value is constant to 2.72wt%, lower the temperature to 50°C, add 76g of acetone, 153.73g of methyl methacrylate, and 6.04g of triethylamine, and stir for 10 minutes until uniform. After cooling down to room temperature, add 450 g of water at a shear rate of 1300 rpm, emulsify and disperse for 10 min, add 14.17 g of tris(4-aminophenyl)amine to the dispersed emulsion, dilute it with 4 times water, and stir for 5 min. Add 1.92g of 4,4-diaminodicyclohexylmethane, dilute it with 4 times of water and add it, and stir for...

Embodiment 2

[0087] Add 80g WANNATEHMDI, 20g hydrogenated castor oil (iodine value 10-15), 60gPCL220N, and 0.18g organic bismuth catalyst, 24g acetone to a four-neck flask equipped with a thermometer, reflux condenser, and stirrer, heat up to 85°C and keep warm for reaction After the NCO value is constant at 11.23wt%, cool down to 55°C, add 10g of dimethylol propionic acid, 12g of 1,4-butanediol and 20g of acetone, and react at 75-80°C for 3-4 hours to reach the NCO value Constant at 2.16wt%, lower the temperature to 40°C, add 77g of acetone, 154.65g of methyl methacrylate, 7.55g of triethylamine, and stir for 10 minutes until uniform. After cooling down to room temperature, add 451g of water at a shear rate of 1300rpm, emulsify and disperse for 10min, add 11.31g of tris(4-aminophenyl)amine to the dispersed emulsion, dilute with 4 times of water, add, and stir for 5min. Add 3.87g of 4,4-diaminodicyclohexylmethane, dilute it with 4 times of water and add it, and stir for 8 minutes.

[0088] ...

Embodiment 3

[0090] Add 80g WANNATE HMDI, 60g hydrogenated castor oil (iodine value 10-15), 20g PNA2000, and 0.18g organic bismuth catalyst, 24g acetone to the four-neck flask equipped with thermometer, reflux condenser and stirrer, heat up to 85°C and keep warm for reaction , when the NCO value is constant at 9.49wt%, cool down to 55°C, add 8g of dimethylolpropionic acid, 7g of 1,4-butanediol and 26.3g of acetone, and react at 75-80°C for 3-4h to NCO The value is constant at 3.07wt%. Cool down to 50°C, add 79g of acetone, 152.77g of methyl methacrylate, and 6.04g of triethylamine, and stir for 10 minutes until uniform. After cooling down to room temperature, add 451g of water at a shear rate of 1300rpm, emulsify and disperse for 10min, add 15.96g of tris(4-aminophenyl)amine to the dispersed emulsion, dilute it with 4 times of water, add it, and stir for 5min. Add 7.64g of 4,4-diaminodicyclohexylmethane, dilute it with 4 times of water and add it, and stir for 8min.

[0091] Add the emuls...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com