Method and device for continuously preparing prasugrel intermediate by countercurrent extraction

An intermediate and extraction technology, applied in the field of medicine, can solve the problems of inability to stir, difficulty, viscosity of the reaction liquid, etc., and achieve the effect of realizing continuous industrial production, simplifying the purification method and reducing the viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

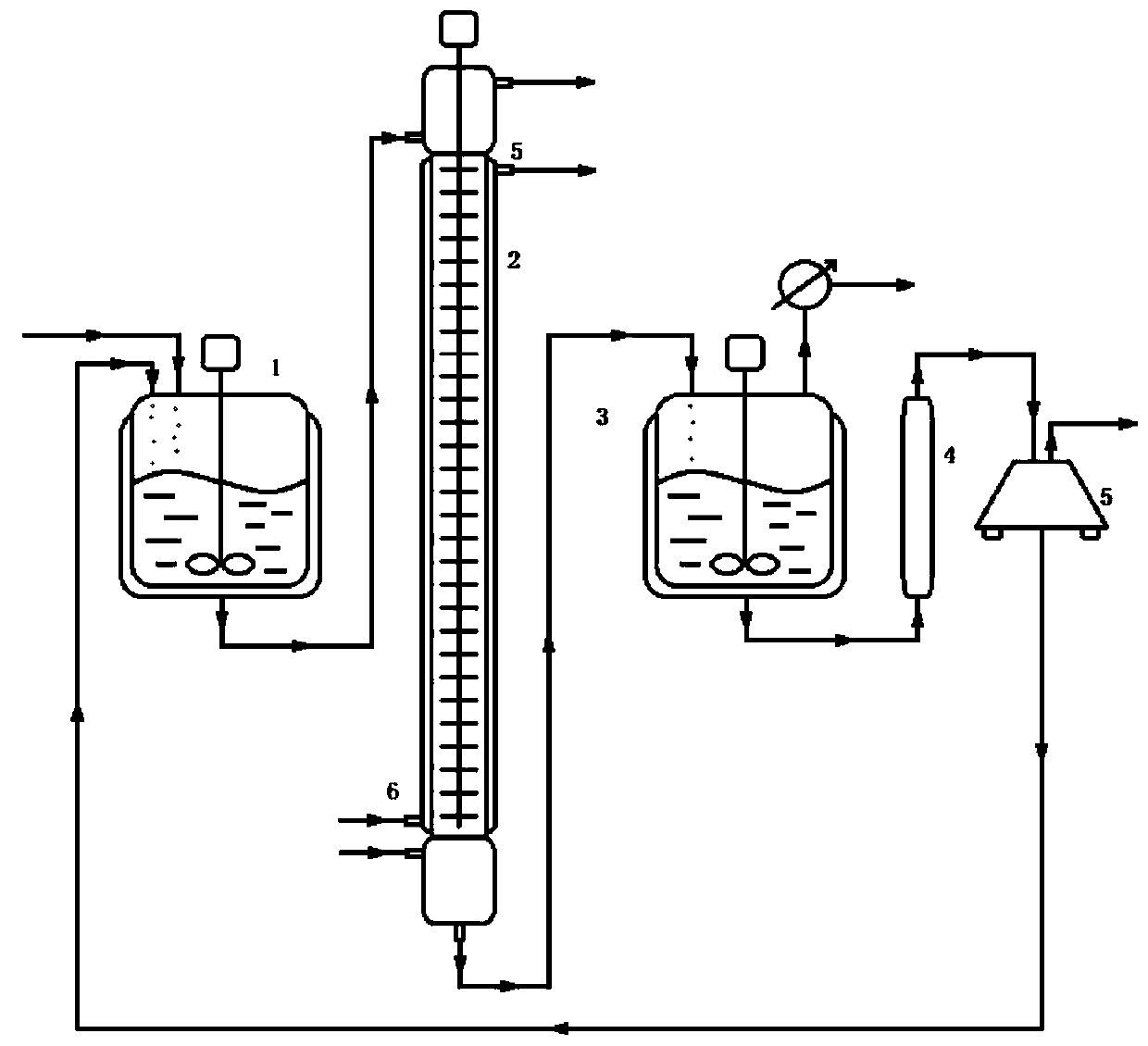

[0043] Embodiment 1: A kind of method and device thereof for the continuous preparation of prasugrel intermediate by countercurrent extraction, as attached figure 1 Shown:

[0044] S1. Pump compound I and compound II molar ratio of 1:1, compound I and triethylamine dichloromethane mixed solution of 1:8 molar ratio into reaction kettle 1 at a flow rate of 10L / h, and heat to 30°C , reaction 6h;

[0045] S2. Pump the feed liquid in the reaction kettle 1 into the top of the turntable tower 2 at a flow rate of 4L / h, and pump purified water from the bottom of the turntable tower 2 at a flow rate of 8L / h at the same time, and adjust the rotating speed of the turntable in the turntable tower 2 to 240rpm for countercurrent extraction;

[0046] S3. The raffinate water phase is discharged from the top of the rotary table tower 2, and the raffinate dichloromethane phase is discharged from the bottom of the rotary table tower 2, and sent to the evaporator 3 for concentration under reduce...

Embodiment 2

[0047] Embodiment 2: A kind of method and device thereof for continuously preparing prasugrel intermediate by countercurrent extraction, as attached figure 1 Shown:

[0048] S1. Compound and compound The molar ratio is 1:1.5, the compound The dichloromethane mixed solution with triethylamine molar ratio of 1:1 was pumped into Reactor 1 at a flow rate of 10L / h, heated to 40°C, and reacted for 8h;

[0049] S2. Pump the feed liquid in the reactor 1 into the top of the turntable tower 2 at a flow rate of 6L / h, and pump purified water from the bottom of the turntable tower 2 at a flow rate of 6L / h at the same time, and adjust the rotating speed of the turntable in the turntable tower 2 to 180rpm. countercurrent extraction

[0050] S3. The raffinate water phase is discharged from the top of the rotary table tower 2, and the raffinate dichloromethane phase is discharged from the bottom of the rotary table tower 2; The dichloromethane distillate obtained is discharged from the...

Embodiment 3

[0051] Embodiment 3: A kind of method and device thereof for the continuous preparation of prasugrel intermediate by countercurrent extraction, as attached figure 1 Shown:

[0052] S1. Compound and compounds The molar ratio is 1:2, the compound The mixed solution of dichloromethane and triethylamine with a molar ratio of 1:2.5 is pumped into the reaction kettle 1 at a flow rate of 10L / h, heated to 10°C, and reacted for 10h;

[0053] S2. Pump the feed liquid in the reactor 1 into the top of the turntable tower 2 at a flow rate of 8L / h, and pump purified water from the bottom of the turntable tower 2 at a flow rate of 2.67L / h at the same time, and adjust the rotation speed of the turntable in the turntable tower 2 to 120rpm Perform countercurrent extraction;

[0054] S3. The raffinate water phase is discharged from the top of the rotary table tower 2, and the raffinate dichloromethane phase is discharged from the bottom of the rotary table tower 2, and sent to the evapora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com