Wood product polishing device

A technology for wood products and coated abrasives, applied in grinding/polishing safety devices, grinding machines, manufacturing tools, etc., can solve the problems of harming workers' health, slow edging processing, poor adaptability of MDF, etc. Dust splash hurts people, improves product quality, and has the same effect of edging depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

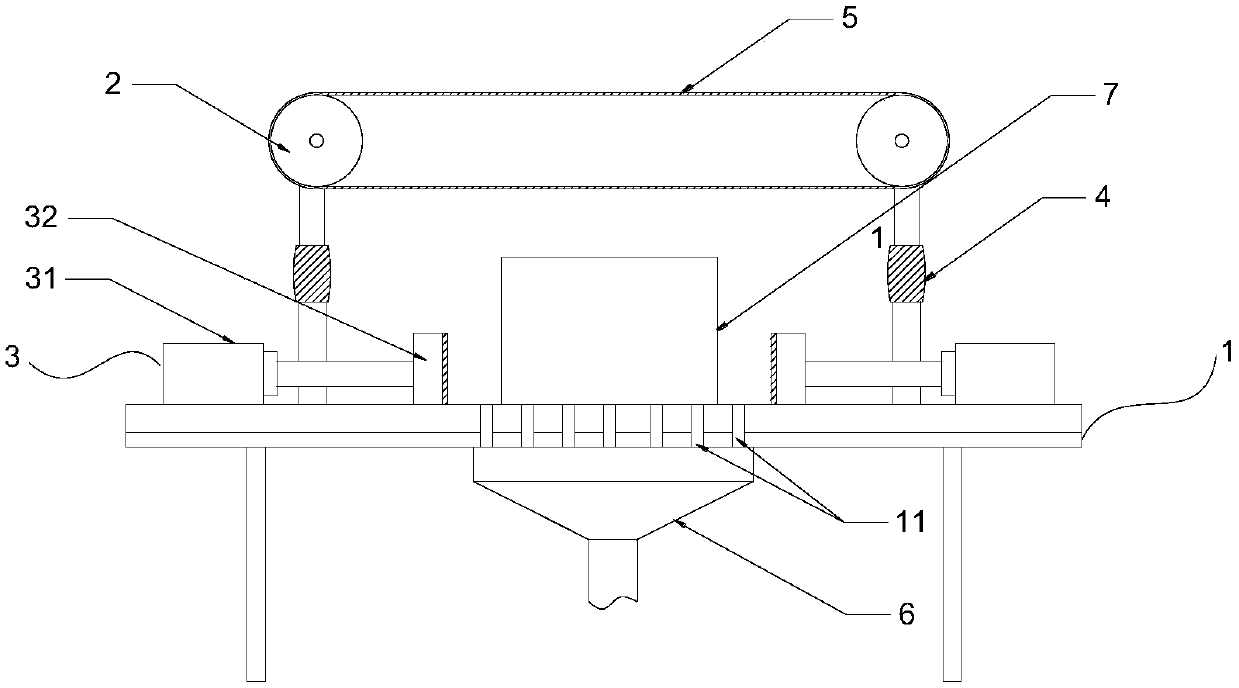

[0024] Such as figure 1 As shown, a wood product grinding device includes a base 1, a conveyor belt 2 and a clamping assembly 3 for clamping a plate 7 to be grinded, the conveyor belt 2 is installed on the base 1 through a support column 4, and the motor Driven, the outer side of the conveyor belt 2 is provided with coated abrasives 5, when working, the conveyor belt 2 abuts against the plate 7 to be ground, and the clamping components 3 are located on both sides of the base 1 and are oppositely arranged. The motor drives the conveyor belt 2 to rotate, thereby driving the coated abrasive tool 5 to rotate, and to perform surface treatment on the plate 7 to be ground between the conveyor belt 2 and the base 1; the plate 7 to be ground is clamped by the clamping assembly 3, and the conveyor belt 2 Press down on the plate 7 to be ground on the base 1, and fix it horizontally and vertically, effectively preventing the plate 7 to be ground from bouncing when grinding, stable work, h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com