Method for preparing high-manganese steel-ceramic-carbon steel composite wear-resistant lining board

A composite wear-resistant liner and high-manganese steel liner technology, which is applied in the field of wear-resistant materials, can solve problems such as shedding, cracks, and easy-aging wear-resistant ceramic blocks, and achieve the effect of preventing shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

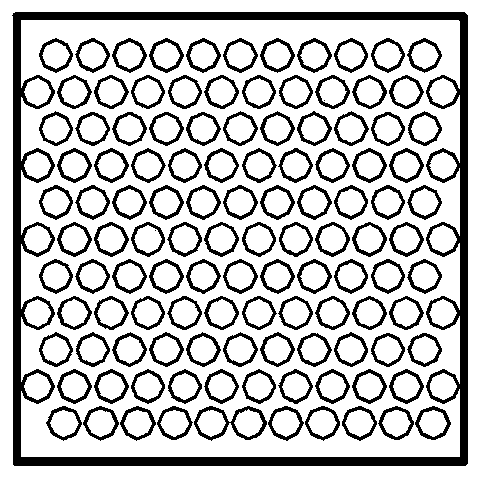

[0025] After smelting the high manganese steel with chemical composition weight percentage (wt%) as C 0.65, Mn 13.1, N 0.016, Mo 0.35, and the rest is Fe and impurities, it is cast as figure 1 The shown porous high manganese steel liner with a thickness of 20mm has a conical through hole shape, the upper diameter of the conical shape is 20mm, and the lower diameter is 25mm. 97% Al by weight 2 o 3 Mix well with 3% SiC powder and sinter to form a ceramic block with the same size as the conical through hole. After cleaning the surface of the ceramic block and the inner wall of the through hole of the high manganese steel liner, apply adhesive, and insert the ceramic block into the through hole. Cut the rubber pad with a thickness of 2mm and the Q235 steel plate with a thickness of 3mm to the same size as the high manganese steel liner. After pasting the rubber pad on the Q235 steel plate, use a welding machine to weld the surrounding edges of the Q235 steel plate to the high ma...

Embodiment 2

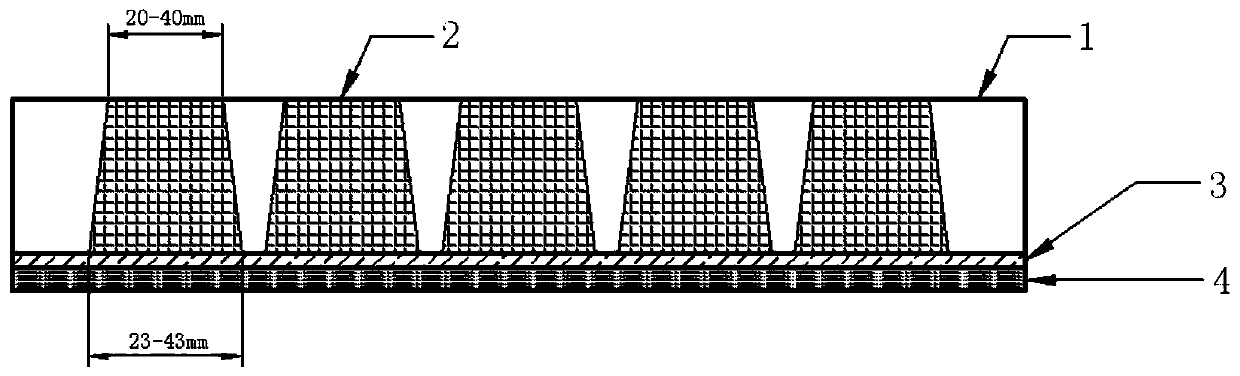

[0029] After the high manganese steel with chemical composition weight percentage (wt%) is C 0.70, Mn 12.9, N 0.021, Mo 0.42, and the rest is Fe and impurities is smelted in an electric arc furnace, it is cast as figure 2 The shown porous high manganese steel liner with a thickness of 15mm has a through hole in the shape of a square cone, the upper side of the square cone is 32mm long and the lower side is 40mm long. 95% Al by weight 2 o 3 Mix well with 5% SiC powder and sinter to form a ceramic block with the same size as the through hole of the square cone. After cleaning the surface of the ceramic block and the inner wall of the through hole of the high manganese steel liner, apply adhesive, and insert the ceramic block into the through hole. Cut the rubber pad with a thickness of 2mm and the Q235 steel plate with a thickness of 3mm to the same size as the high manganese steel liner. After pasting the rubber pad on the Q235 steel plate, use a welding machine to weld the ...

Embodiment 3

[0031] After the high manganese steel with chemical composition weight percentage (wt%) is C 0.55, Mn 12.3, N 0.018, Mo 0.32, and the rest is Fe and impurities is smelted in an electric arc furnace, it is cast as figure 2 The shown porous high manganese steel liner with a thickness of 16mm has a through hole in the shape of a square cone, the length of the upper side of the square cone is 28mm, and the length of the lower side is 35mm. 96% Al by weight 2 o 3 Mix well with 4% SiC powder and sinter to form a ceramic block with the same size as the through hole of the square cone. After cleaning the surface of the ceramic block and the inner wall of the through hole of the high manganese steel liner, apply adhesive, and insert the ceramic block into the through hole. Cut the rubber pad with a thickness of 2mm and the Q235 steel plate with a thickness of 3mm to the same size as the high manganese steel liner. After pasting the rubber pad on the Q235 steel plate, use a welding m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Lower diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com