Conductor paste and conductor material

A technology of conductive paste and organic carrier, applied in the direction of conductive materials dispersed in non-conductive inorganic materials, cable/conductor manufacturing, non-adjustable metal resistors, etc., can solve the problems of increasing production costs, achieve silver content reduction, Effect of improving electrical conductivity and solving production cost problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

[0028] The compositions of the conductor pastes of Examples 1 to 4 of the present invention are shown in Table 1 below.

[0029] Table 1

[0030]

[0031]

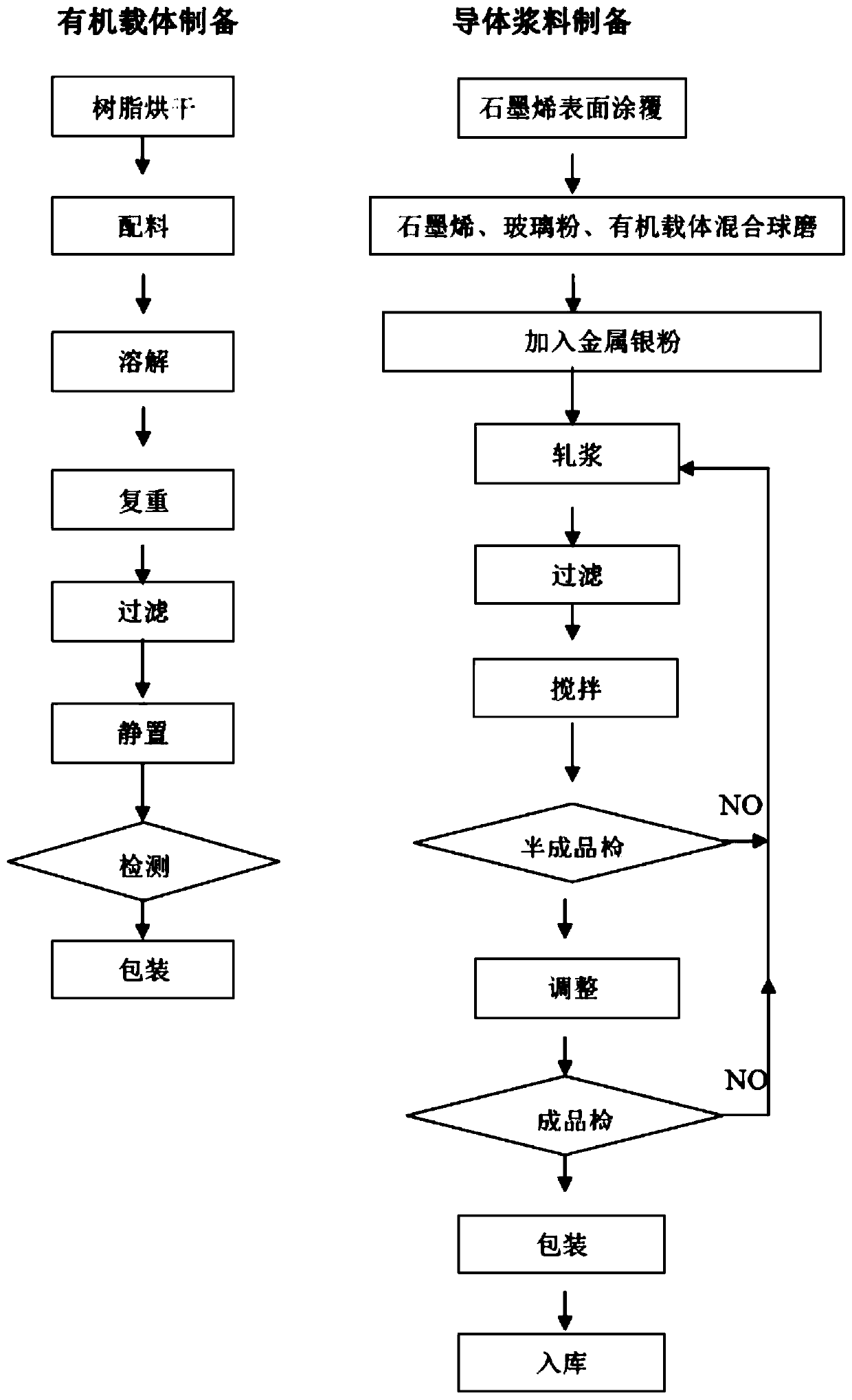

[0032] In above-mentioned embodiment, the preparation / processing method of graphene, glass powder, organic vehicle and embodiment 1~5 conductor slurry is as follows:

[0033] Graphene surface coating: add a surfactant to the graphene, soak and wet the graphene with the surfactant for 6 hours, and then dry it at 60°C for use. A layer of material is coated on the surface of graphene to protect it and facilitate the subsequent air environment operation process. The coated material will also make graphene evenly disperse into the carrier system.

[0034] The preparation method of the glass powder is as follows: use a planetary ball mill to grind glass (such as glass-ceramic) for 3 hours, and use it after detection.

[0035] The preparation method of the organic carrier is as follows: firstly dry the polymer resin, then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com