Aqueous solution developed dry film photoresist

A photoresist and aqueous solution technology, applied in the field of circuit board production, can solve problems such as poor sealing and affect the production quality of circuit boards, and achieve the effect of improving strength, helping production control, and reducing use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0066] Prepare dry film photoresists according to the formula in Table 1 below, wherein, Examples 1 to 5 are dry film photoresists according to the present invention, and the comparative example is an existing dry film photoresist, specifically as follows :

[0067] Table 1 Composition of various dry film photoresists

[0068]

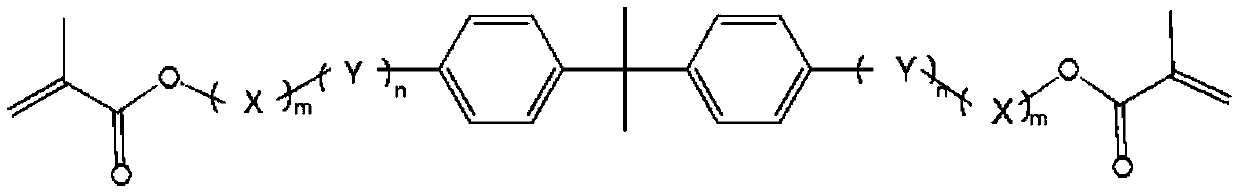

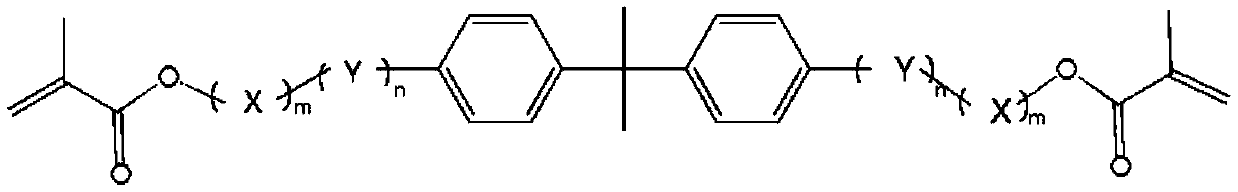

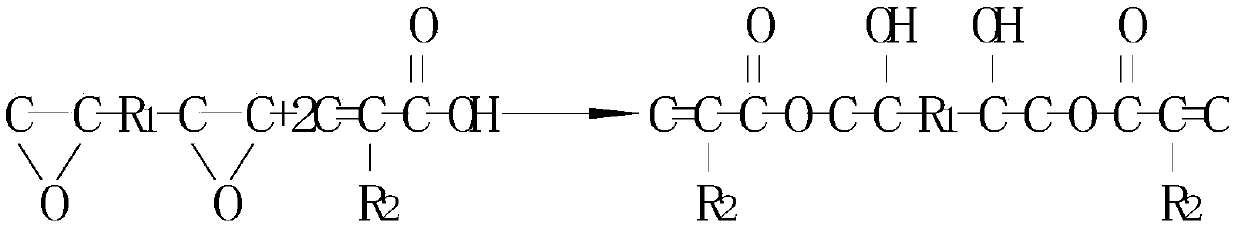

[0069] In the above table 1, acrylate adhesive A is polymerized by 60wt% methacrylate, 18wt% methacrylic acid and 22wt% n-butyl acrylate in butanone solvent; Acrylic acid modification), the double bond content is 5mol; in the B2 structure (using methacrylic acid modification), the double bond content is 5mol; what the photocuring monomer B3 uses is trimethylolpropane triacrylate (TMPTA); The active monomer D used was SR480, which was purchased from Sartomer Corporation of the United States; p-methoxyphenol was used as a thermal polymerization inhibitor; the plasticizer was tributyl citrate (TBC).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com