Composite nano-adsorption material, preparation method and application thereof

A nano-adsorption material and nano-particle technology, applied in the field of preparation and composite nano-adsorption materials, can solve the problems of easy hydrolysis and reduce the adsorption capacity of heavy metal ions, and achieve the effects of reducing the degree of hydrolysis, improving the hydrophobicity and improving the adsorption efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

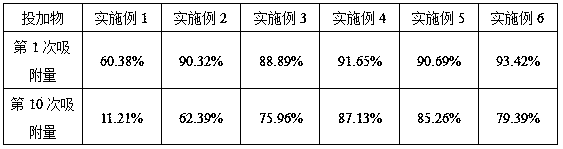

Examples

preparation example Construction

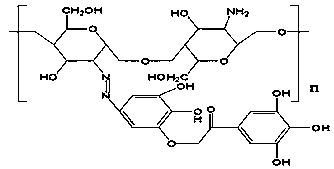

[0021] In order to solve the above problems, a preparation method of a composite nano-adsorbent material is designed, which includes the following steps:

[0022] S1, Preparation of nanoparticles: the and Mix according to the molar ratio of 1: (0.5-0.8), and dissolve in deionized water, then add ammonia water dropwise to the mixed solution, adjust the pH to 9-11, and stir vigorously under the protection of inert gas. After the mixed solution turns from orange red to black, continue to react for 15-30 minutes, centrifuge to obtain a black powder, wash it repeatedly with deionized water until neutral, and dry it in a vacuum environment at 70-90°C to obtain nanoparticles.

[0023] S2, Preparation of nanoparticles: the prepared as described in step S1 Add 0.1-0.5g of nanoparticles into 100-1000mL of 80% ethanol solution with a mass concentration of 80%, add 2-6mL tetraethyl orthosilicate, then add ammonia water dropwise to the mixed solution, adjust the pH to 10-11, St...

Embodiment 1

[0037] Preparation of nanoparticles: 3.5584 g of and 1.9476g of Mix and dissolve in 2500ml of deionized water, then add ammonia water dropwise to the mixed solution, adjust the pH to 10.0, and stir vigorously under the protection of an inert gas until the mixed solution turns from orange red to black, then continue the reaction for 30 minutes. Centrifuge to obtain a black powder, wash it repeatedly with deionized water until neutral, and dry it under a vacuum environment at 85°C to obtain nanoparticles;

[0038] Preparation of nanoparticles: the prepared Add 0.2 g of nanoparticles into 200 mL of 80% ethanol solution with a mass concentration of 80%, add 3 mL of tetraethyl orthosilicate, then add ammonia water to the mixed solution dropwise, adjust the pH to 10.0, stir at room temperature for 9 h, and then pass through the magnetic Separation and washing with deionized water Repeated washing with deionized water to neutrality, drying in a vacuum environment at 85°C, ...

Embodiment 2

[0040] This embodiment is carried out on the basis of embodiment 1.

[0041] Preparation of composite nano-adsorbent material: the prepared in Example 1 Add 0.2 g of nanoparticles into 200 mL of 80% ethanol solution, then add 3 mL of tetraethyl orthosilicate, 0.5 g of chitosan, and 0.1 g of sodium fluoride in batches as a catalyst, and stir at room temperature for 24 h. Then magnetically separate, wash with deionized water repeatedly until neutral, and dry under vacuum at 36°C to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com