Telmisartan capsule and preparation method thereof

A technology for telmisartan and capsules, applied in the field of telmisartan capsules and preparation thereof, can solve the problems of easy electrostatic adsorption, increased operation difficulty, and high equipment requirements, achieves improved dissolution rate and compressibility, and ensures rapid The effect of dissolution and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

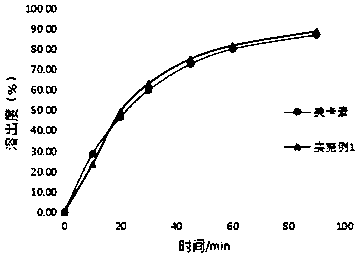

Embodiment 1

[0061] A kind of telmisartan capsule, by weight, raw material composition is as shown in table 1.

[0062] Table 1

[0063]

[0064]

[0065] The preparation process is:

[0066] (1) sodium hydroxide is dissolved in 48g aqueous solution, obtains sodium hydroxide solution;

[0067] (2) Weigh respectively Telmisartan, lactose, microcrystalline cellulose, poloxamer 188, sodium carboxymethyl starch, povidone K30, and magnesium stearate to pass through a 60-mesh sieve for subsequent use;

[0068] (3) Add telmisartan, lactose, microcrystalline cellulose, carboxymethyl starch sodium, and povidone K30 into the wet granulator in sequence, turn on the stirring blade, and pre-mix for 5 minutes; then turn on the cutter, and set the speed At 1850r / min, slowly add the solution described in step (1) for wet granulation, and granulate for 5min;

[0069] (4) The wet granules are sent to the fluidized bed for drying, the drying temperature is 55°C, the drying time is 35 minutes, and th...

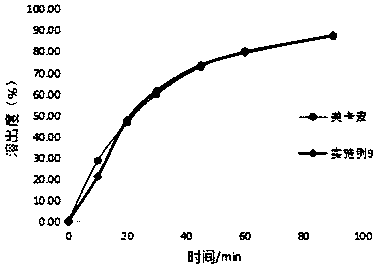

Embodiment 2

[0073] A kind of telmisartan capsule, by weight, raw material components are as shown in table 2.

[0074] Table 2

[0075]

[0076] The preparation process is:

[0077] (1) sodium hydroxide is dissolved in 58g aqueous solution, obtains sodium hydroxide solution;

[0078] (2) Take by weighing telmisartan, sodium lauryl sulfate, mannitol, corn starch, crospovidone, hypromellose, sodium stearyl fumarate and pass through an 80-mesh sieve for subsequent use;

[0079] (3) Add telmisartan, sodium lauryl sulfate, mannitol, corn starch, crospovidone, and hypromellose into the wet granulator in sequence, turn on the stirring blade, and pre-mix for 3 minutes; then Turn on the cutter, set the rotating speed to 1500r / min, slowly add the solution described in step (1) for wet granulation, and granulate for 3min;

[0080] (4) The wet granules are sent to the fluidized bed for drying, the drying temperature is 60°C, the drying time is 30 minutes, and the moisture content of the granule...

Embodiment 3

[0084] A kind of telmisartan capsule, by weight, raw material components are as shown in table 3.

[0085] table 3

[0086]

[0087] The preparation process is:

[0088] (1) sodium hydroxide is dissolved in 50g water, obtains sodium hydroxide solution;

[0089] (2) Weigh and weigh Telmisartan, mannitol, sodium lauryl sulfate, poloxamer 188, crospovidone, sodium carboxymethylcellulose, and magnesium stearate over 40 meshes respectively. sieve, spare;

[0090] (3) Add telmisartan, mannitol, sodium lauryl sulfate, poloxamer 188, crospovidone, and sodium carboxymethylcellulose into the wet granulator in sequence, turn on the stirring blade, and pre- Mix for 2 minutes; then turn on the cutter, set the speed to 2000r / min, slowly add the solution described in step (1) for wet granulation, and granulate for 6 minutes;

[0091] (4) The wet granules are sent to the fluidized bed for drying, the drying temperature is 70°C, the drying time is 20min, and the moisture content of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com