A method for optimizing the conditions of two-phase extraction and its application

An optimization method, a two-phase technology, which is applied in the preparation methods of peptides, chemical instruments and methods, biochemical equipment and methods, etc., can solve the problems of large experimental workload, inconsistency, and difficulty in quickly finding a two-phase system, etc., To achieve the effect of high economic efficiency, not easy to denature inactivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1: the optimization method summary of two-phase extraction condition

[0045] A method for optimizing the conditions of two-phase extraction, also known as "5 2 *3+1 aqueous two-phase experiment method”, taking PEG / salt two-phase aqueous phase as an example, includes the following steps:

[0046] 1) Determine the two-phase type used in two-phase extraction, which is the first phase and the second phase; among the present embodiment, the first phase is PEG, and the second phase is salt (such as sodium dihydrogen phosphate, ammonium sulfate, etc. );

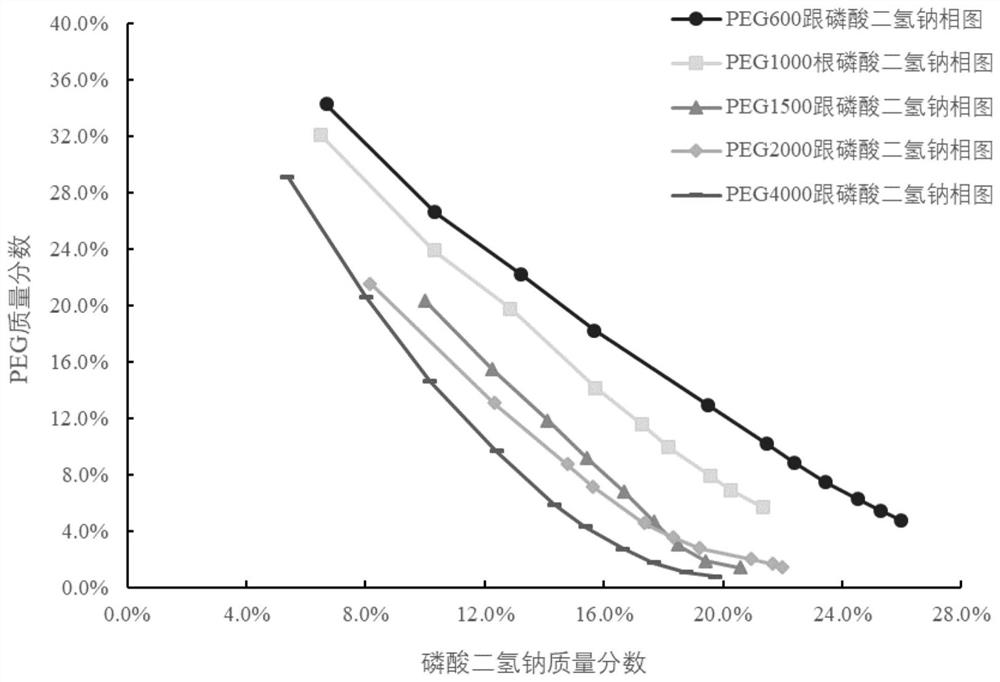

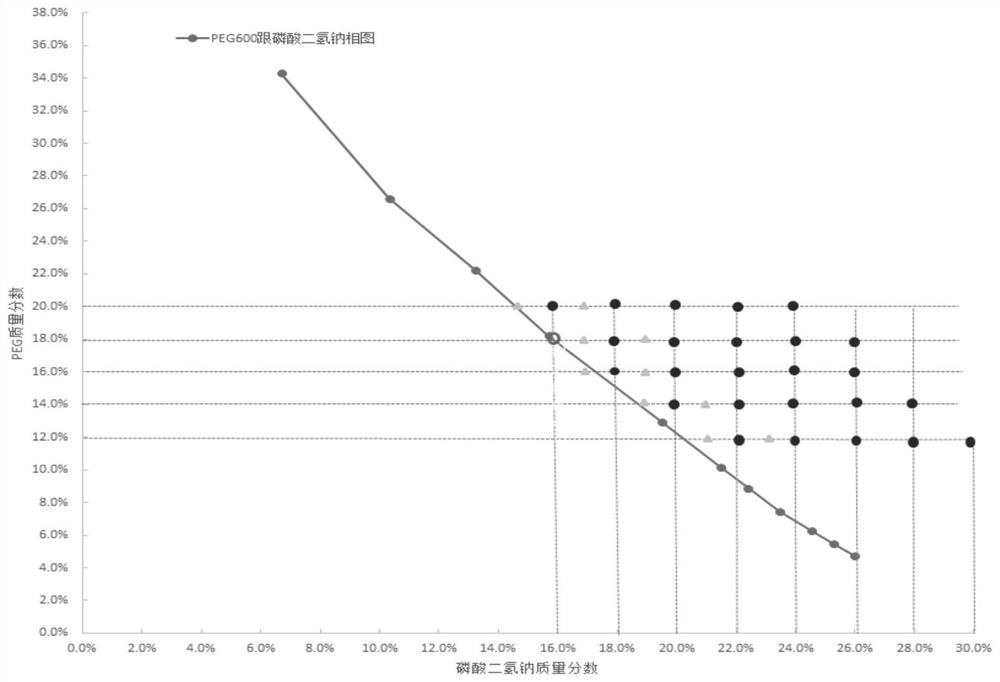

[0047]2) Take the mass fraction of the first phase PEG as the vertical axis and the mass fraction of the second phase salt as the horizontal axis to draw a phase diagram;

[0048] 3) Based on the two-node line of the phase diagram, select five critical phase-forming points located at the center of the two-node line, and the PEG mass fraction interval between two adjacent points among the five critical phase-form...

Embodiment 2

[0054] Example 2: Taking the separation and purification of β-glucosidase from abalone viscera as an example to illustrate the optimization method of two-phase extraction conditions

[0055] 1. Raw materials and reagents

[0056] The viscera of wrinkled abalone, provided by the School of Ocean and Earth Sciences, Xiamen University, was stored frozen at -20°C until use; p-nitrophenyl-β-D-glucopyranoside (p-NPG): Beijing Suolaibao Technology Co., Ltd.; p-nitrophenol, sodium carbonate, sodium dihydrogen phosphate (NaH 2 PO 4 ), citric acid, acetic acid, sodium acetate, sodium hydroxide (all of analytical grade), polyethylene glycol (Polyethylene glycol, PEG) 600, 1000, 1500, 2000, 4000: Sinopharm Chemical Reagent Co., Ltd.

[0057] 2. Instruments and equipment

[0058] High-speed tissue masher: A25 emulsifier, Shanghai Ouhe; ultrasonic cell crusher: Scientz-ⅡD, Ningbo Xinzhi Biotechnology Co., Ltd.; high-speed refrigerated centrifuge: sigma 3-18K, Germany; ice machine: AF100, ...

Embodiment 3

[0087] Example 3: Explore the optimal conditions and rules for the separation and purification of β-glucosidase from abalone viscera by optimizing the conditions of two-phase extraction

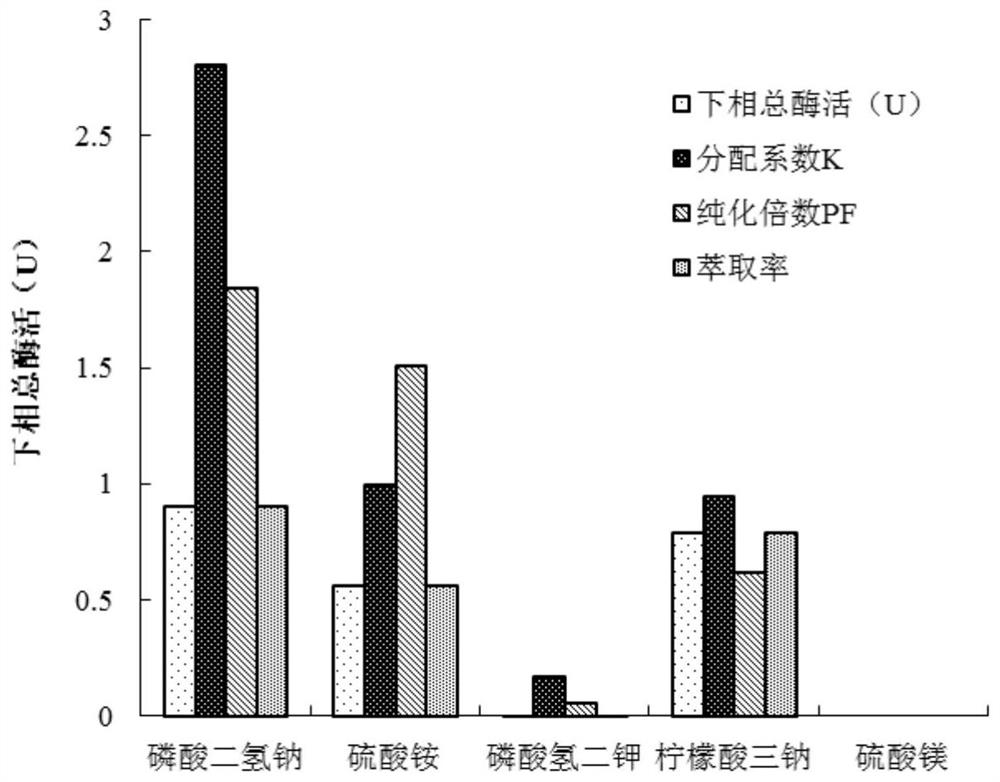

[0088] 1. The effect of the composition of the two-phase system on the extraction effect of β-glucosidase

[0089] Reference Example 2, using abalone viscera homogenate as raw material, using the optimization method of two-phase extraction conditions "5 2 *3+1 two-phase aqueous phase experiment method", using PEG / salt two-phase aqueous system to separate and purify β-glucosidase from abalone viscera, and explore PEG600 / 1000 / 1500 / 2000 / 4000 (PEG400 is too small due to molecular weight, The extraction effect is not good; PEG6000 has too large a molecular weight and is too viscous, and the measurement effect of the extraction effect is not good, so there is no comparison significance, so the experiment has been excluded) After the construction of the optimal two-phase system for extracting β-gluc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com