Adhesive for label clamping position of beer bottle labeling machine and preparation method

A labeling machine and label holder technology, applied in the direction of adhesive type, ester copolymer adhesive, non-polymer adhesive additives, etc., can solve the problems of label "label printing, bubbling and wrinkles, etc. Achieve the effect of improving stability, strong adhesion, and less dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

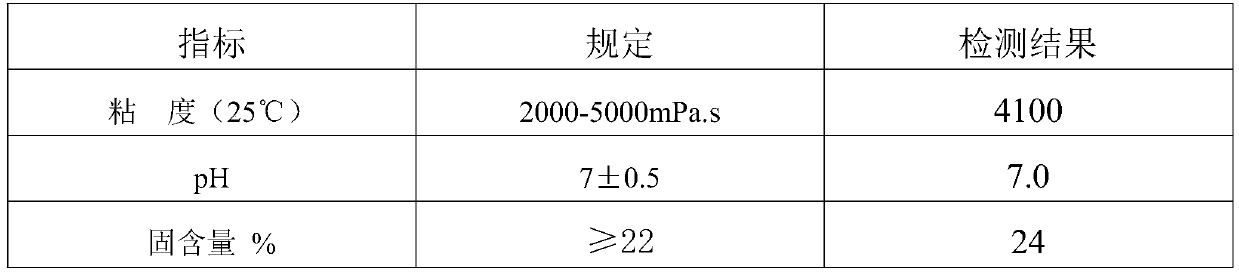

Image

Examples

Embodiment 1

[0023] This embodiment provides an adhesive for the position of the label clip of a beer bottle labeling machine, which is made of the following raw materials in parts by weight: 120 parts of polyvinyl alcohol with a degree of polymerization of 1700, 3 parts of emulsified silicone oil, and a molecular weight of 250 parts of 2000-5000 alkali-soluble acrylate emulsion, 35 parts of sodium abietate, 18 parts of zinc oxide, 15 parts of ammonium zirconium carbonate, 2 parts of Kathon, 12 parts of ammonia water, and 500 parts of water.

[0024] This embodiment is used for the preparation method of the adhesive in the label clip position of the beer bottle labeling machine, comprising the following steps:

[0025] (1) Add water to the reaction kettle, then polyvinyl alcohol and emulsified silicone oil, heat up to 85°C, and keep it warm for 1 hour;

[0026] (2) Add alkali-soluble acrylate emulsion and sodium rosinate in sequence, and then add 3 parts of ammonia water to adjust the pH v...

Embodiment 2

[0033] This embodiment provides a kind of adhesive for the position of the label clip of the beer bottle labeling machine, which is made of the following raw materials in parts by weight: 100 parts of polyvinyl alcohol with a degree of polymerization of 1700, 4 parts of emulsified silicone oil, and a molecular weight of 150 parts of alkali-soluble acrylate emulsion of 2000-5000, 50 parts of sodium abietate, 5 parts of zinc acetate, 25 parts of ammonium zirconium carbonate, 1 part of Kathon, 20 parts of ammonia water, and 450 parts of water.

[0034] This embodiment is used for the preparation method of the adhesive in the label clip position of the beer bottle labeling machine, comprising the following steps:

[0035] (1) Add water to the reaction kettle, then polyvinyl alcohol and emulsified silicone oil, heat up to 80°C, and keep it warm for 1 hour;

[0036] (2) Add alkali-soluble acrylate emulsion and sodium rosinate in sequence, and then add 15 parts of ammonia water to ad...

Embodiment 3

[0043] This embodiment provides an adhesive for the position of the label clip of a beer bottle labeling machine, which is made of the following raw materials in parts by weight: 150 parts of polyvinyl alcohol with a degree of polymerization of 1700, 2 parts of emulsified silicone oil, and a molecular weight of 300 parts of 2000-5000 alkali-soluble acrylate emulsion, 20 parts of sodium abietate, 30 parts of zinc acetate, 5 parts of potassium zirconium carbonate, 3 parts of Kathon, 5 parts of ammonia water, and 550 parts of water.

[0044] This embodiment is used for the preparation method of the adhesive in the label clip position of the beer bottle labeling machine, comprising the following steps:

[0045] (1) Add water into the reaction kettle, then polyvinyl alcohol and emulsified silicone oil, heat up to 90°C, and keep it warm for 1 hour;

[0046] (2) Add alkali-soluble acrylate emulsion and sodium rosinate in sequence, and then add 2 parts of ammonia water to adjust the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com