ABS/NPG-PET alloy material and preparation method thereof

An alloy material and weight technology, applied in the field of ABS/NPG-PET alloy material and its preparation, can solve the problems such as strength and weather resistance limit ABS application, poor toughness, etc., and achieve good thermal oxidation resistance and anti-UV performance, The effect of reducing flow difference and slowing down flow marks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

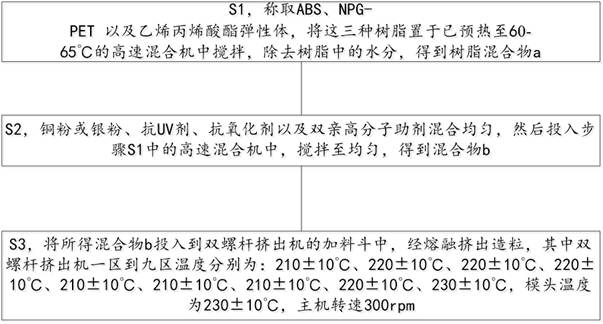

[0038] Please refer to figure 1 , the present invention further provides a kind of preparation method of above-mentioned ABS / NPG-PET alloy material, comprises the following steps:

[0039] S1, weigh ABS, NPG-PET and ethylene acrylate elastomer, place these three resins in a high-speed mixer preheated to 60-65°C and stir, remove the moisture in the resin, and obtain resin mixture a;

[0040] S2, copper powder or silver powder, anti-UV agent, antioxidant and amphiphilic polymer additives are mixed evenly, and then put into the high-speed mixer in step S1, stirred until uniform, and mixture b is obtained;

[0041] S3, put the obtained mixture b into the hopper of the twin-screw extruder, and granulate through melt extrusion, wherein the temperatures in the first zone to the ninth zone of the twin-screw extruder are: 210±10°C, 220±10°C, 220±10℃, 220±10℃, 210±10℃, 210±10℃, 210±10℃, 220±10℃, 230±10℃, the die head temperature is 230±10℃, the host speed is 300rpm.

Embodiment 1

[0043] Weigh 70 parts by weight of ABS, 30 parts by weight of NPG-PET, and 5 parts by weight of ethylene acrylate elastomer, and stir these three resins in a high-speed mixer that has been preheated to 65°C to remove the moisture to obtain resin mixture a; 0.6 parts by weight of copper powder, 0.4 parts by weight of anti-UV agent, 0.3 parts by weight of antioxidant and 0.3 parts by weight of amphiphilic polymer additives are mixed evenly, and then put into the high-speed mixing in step S1 Put the obtained mixture b into the hopper of the twin-screw extruder, and granulate through melt extrusion, wherein the temperature of the first zone to the ninth zone of the twin-screw extruder is respectively: 210 ±10℃, 220±10℃, 220±10℃, 220±10℃, 210±10℃, 210±10℃, 210±10℃, 220±10℃, 230±10℃, the die temperature is 230± 10°C, host speed 300rpm.

Embodiment 2

[0045] It is basically the same as Example 1, except that 7 parts by weight of ethylene acrylate elastomer is added.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com