Macromolecular photoinitiator, preparation method and applications thereof

A photoinitiator and macromolecular technology, applied in the field of photocuring, can solve the problems of easy yellowing, difficult to dissolve, low solubility, etc., and achieve the effects of good solubility and stability, reduced thermal shrinkage, and high polymerization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

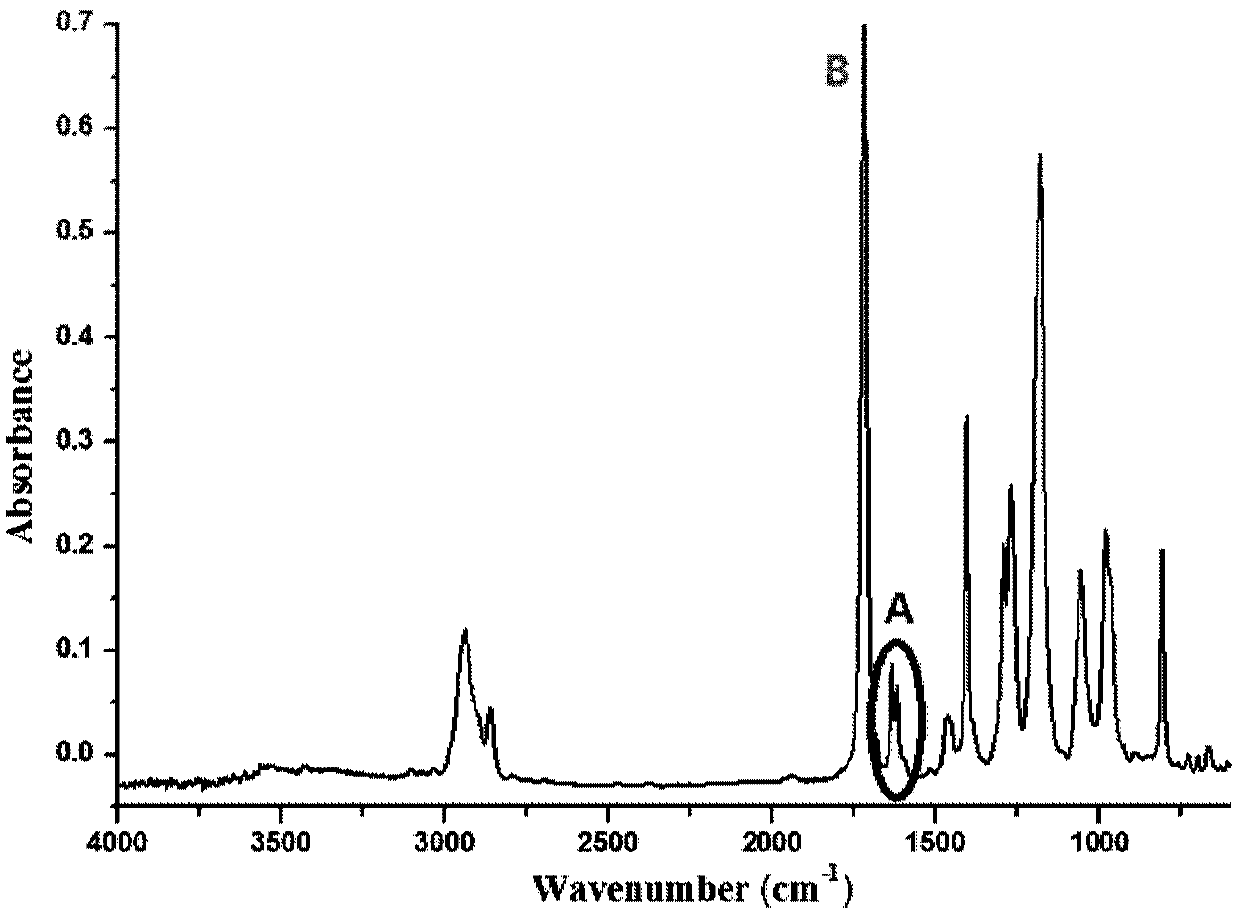

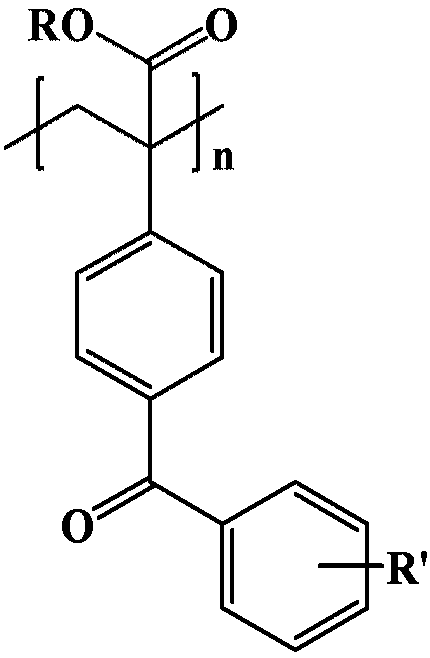

[0049] Example 1. Poly 4-(2-methylacrylate)benzophenone Synthesis

[0050]

[0051] Add 48g of methanol (1.5mol) into a 250mL three-necked flask and stir, raise the temperature to reflux, slowly add 42g of diketene (0.5mol), continue to react at reflux temperature for 5h, and distill under reduced pressure to obtain 89.4g (0.77mol) of methyl acetoacetate .

[0052] Add 200mL THF and 15.6g stirred and dispersed NaH (60% dispersed in mineral oil, 0.39mol) to a 500mL three-necked flask protected by argon, and 34.8g methyl acetoacetate (0.3mol) is added dropwise to the flask at room temperature in and stir well. When the liquid in the flask became clear, 46.8 g of iodomethane (0.33 mmol) was added dropwise, the mixture was stirred at 40° C. for 10 h, the reaction solution was quenched with saturated aqueous ammonium chloride and extracted 3 times with ethyl acetate. The combined organic layers were dried with anhydrous sodium sulfate and spin-dried to dry the solvent, and s...

Embodiment 2

[0069] Example 2. Poly 4-(2-ethyl acrylate) benzophenone F-2 Synthesis

[0070]

[0071] The synthesis process of F-2 refers to the synthesis of F-1, the difference is that the methanol used in A-1 is replaced with ethanol.

[0072] NMR data of E-2: 1 HNMR (300Hz) in DMSO: δ 1.07ppm (t, 3H), 4.00ppm (q, 2H), 6.19, 6.37ppm (d, J=58.3, 2H), 7.41-7.84ppm (m, 9H).

[0073] F-2 Molecular weight data: M w = 8500, PDI = 1.49.

Embodiment 3

[0074] Example 3. Poly 4'-methoxy, 4-(2-acrylate ethyl) benzophenone F-3 Synthesis

[0075] The synthesis process of F-3 refers to the synthesis of F-1, the difference is that the raw material E-3 for the synthesis of F-3 is the 4-bromobenzophenone used in E-1 with 4-bromo, 4'-methoxy Base benzophenone C-1 instead, the synthetic method of C-1 is as follows:

[0076]

[0077] Add 21.95g of 4-bromobenzoyl chloride (0.1mol) and 17.3g of anhydrous aluminum trichloride (0.13mol) to a 500mL three-necked flask, and add 100mL of CH 2 Cl 2 The solid was dissolved, placed in a low-temperature reaction bath at 10°C, and stirred. 140.6g anisole (0.13mol) and 50ml CH 2 Cl 2 Mix well, add to constant pressure dropping funnel and start dropping. After the dropwise addition, add 20mL CH2 Cl 2 Rinse the constant-pressure dropping funnel, slowly raise the temperature of the cooling bath to 20°C, and continue stirring. At the end of the reaction, the reactants were slowly poured into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com