Application of Modified Mussel Shell Packing Biological Aerated Filter for Sewage Treatment

A mussel shell modification technology, applied in sustainable biological treatment, biological water/sewage treatment, aerobic process treatment, etc., to achieve strong operability, convenient operation, and good environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

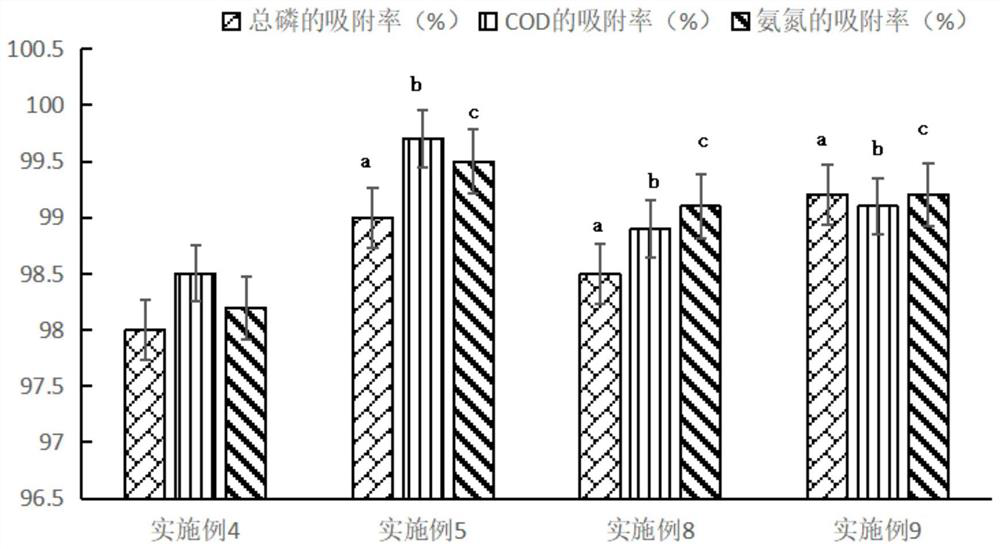

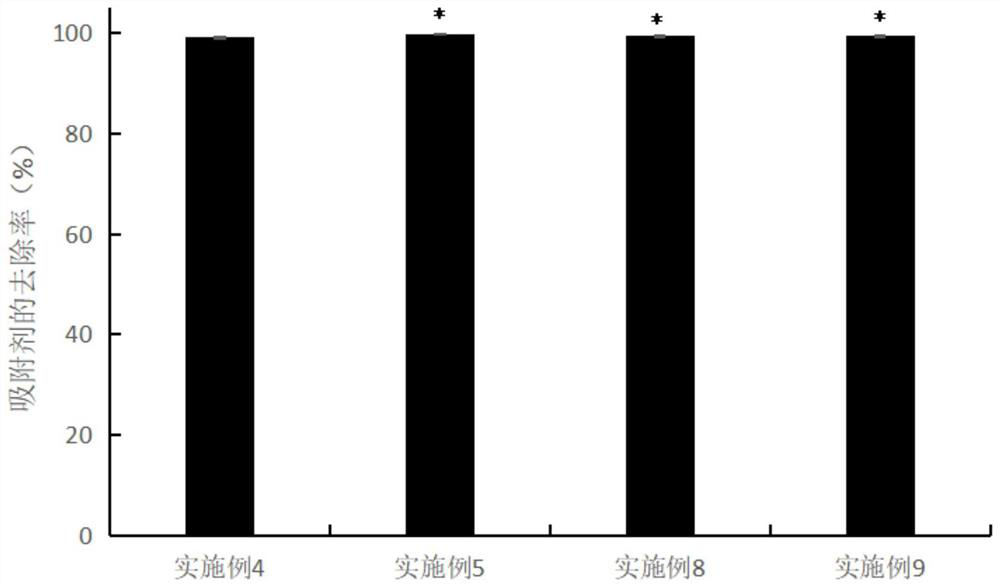

Examples

Embodiment 1

[0031] A preparation method of modified mussel shell filler, comprising the following steps:

[0032] S1. Preparation of magnetic nanoparticles: In a nitrogen atmosphere, 1g of ferric chloride hexahydrate and 2g of ferrous chloride tetrahydrate were heated up to a reaction temperature of 50°C, and then 10mL of 20wt% ammonia water was added dropwise, and reacted at a constant temperature under nitrogen protection for 2h. to room temperature, the synthesized magnetic nanoparticles were washed three times with deionized water, separated by a magnet, and set aside;

[0033] S2. Pre-treatment of mussel shells: clean the mussel shells brought back from the farm, remove the remaining shell meat, silk, and moss on the surface, dry them at 100°C, and put them into a high-temperature resistance furnace for high-temperature carbonization under nitrogen protection. Raise the temperature by 50°C every 10 minutes, up to 800°C, cool down after carbonization for 30 minutes, grind finely, and ...

Embodiment 2

[0037] A preparation method of modified mussel shell filler, comprising the following steps:

[0038] S1. Preparation of magnetic nanoparticles: In a nitrogen atmosphere, 1g of ferric chloride hexahydrate and 3g of ferrous chloride tetrahydrate are heated to a reaction temperature of 60°C, and then 30mL of 24wt% ammonia water is added dropwise. to room temperature, the synthesized magnetic nanoparticles were washed three times with deionized water, separated by a magnet, and set aside;

[0039] S2. Pre-treatment of mussel shells: clean the mussel shells brought back from the farm, remove the remaining shell meat, silk, and moss on the surface, dry them at 100°C, and put them into a high-temperature resistance furnace for high-temperature carbonization under nitrogen protection. Raise the temperature by 50°C every 10 minutes, up to 800°C, cool down after carbonization for 30 minutes, grind finely, and set aside;

[0040] S3. Preparation of magnetic mussel shells: Add 2g of mag...

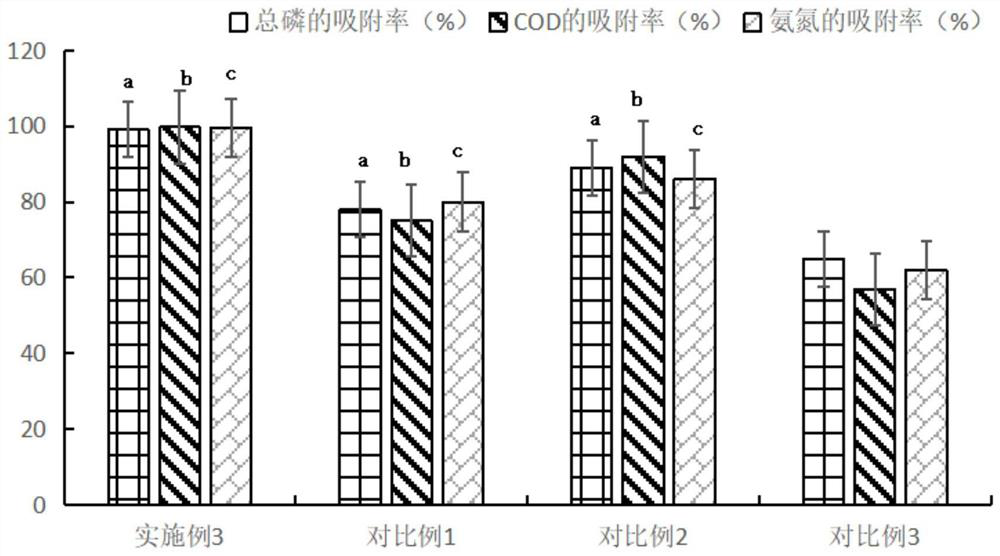

Embodiment 3

[0043] A preparation method of modified mussel shell filler, comprising the following steps:

[0044] S1. Preparation of magnetic nanoparticles: 1g of ferric chloride hexahydrate and 2.5g of ferrous chloride tetrahydrate were heated to a reaction temperature of 55°C in a nitrogen atmosphere, then 20mL of 22wt% ammonia water was added dropwise, and reacted at constant temperature for 3.5h under nitrogen protection , down to room temperature, the synthesized magnetic nanoparticles were washed three times with deionized water, separated by a magnet, and set aside;

[0045] S2. Pre-treatment of mussel shells: clean the mussel shells brought back from the farm, remove the remaining shell meat, silk, and moss on the surface, dry them at 100°C, and put them into a high-temperature resistance furnace for high-temperature carbonization under nitrogen protection. Raise the temperature by 50°C every 10 minutes, up to 800°C, cool down after carbonization for 30 minutes, grind finely, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com