Bamboo wood reinforcing and synergistic treatment method

A treatment method and enhanced treatment technology, applied in wood treatment, wood treatment details, wood impregnation and other directions, can solve the problems of poor anti-mold and anti-corrosion performance, insufficient strength and hardness, and achieve improved anti-mold and anti-corrosion performance, enhanced dimensional stability, The effect of improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1: early rotted masson pine enhanced treatment

[0049] Test material: early rotten masson pine (50×50×20mm length×width×thickness)

[0050] Put the enhanced synergistic treatment solution 1 in a vacuum reactor, completely immerse the sample, evacuate to 20mbar, keep the vacuum for 3-6h, dry at 103°C to constant weight, impregnate again, and impregnate-dry for 4 cycles. Then the enhanced synergistic treatment solution 3 is soaked and dried for 3 cycles as above.

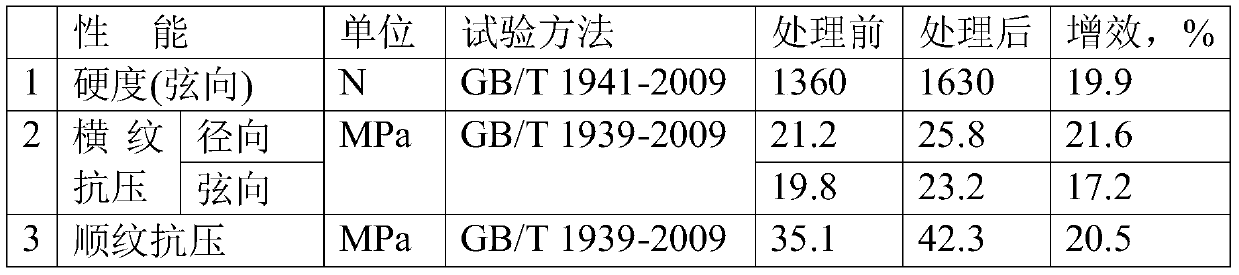

[0051] The performance test results before and after the initial rotten masson pine treatment are shown in Table 1:

[0052] Table 1

[0053]

[0054]

[0055] It can be seen that the hardness and compressive strength are enhanced after treatment, and the volume shrinkage rate is reduced.

Embodiment 2

[0056] Embodiment 2: Phyllostachys synergistic treatment

[0057] Test material: moso bamboo (50×50×20mm length×width×thickness)

[0058] Put the enhanced and synergistic treatment solution 2 in a vacuum reactor, completely immerse the sample, vacuumize to 20mbar, keep the vacuum for 3-6h, dry to constant weight at 103°C, and impregnate again for 8 cycles.

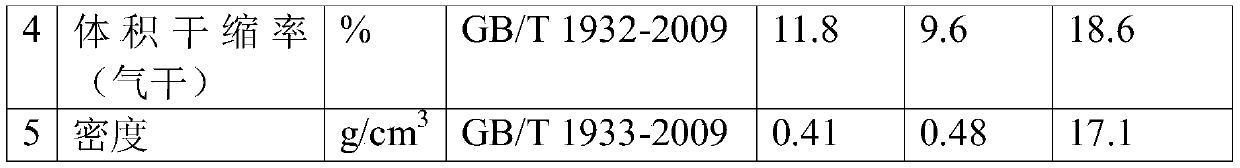

[0059] The performance test results before and after the treatment of moso bamboo are shown in Table 2:

[0060] Table 2

[0061]

[0062] It can be seen that the volume shrinkage rate after treatment is reduced, and its anti-mildew performance is also significantly improved.

Embodiment 3

[0063] Embodiment 3: fast-growing poplar enhanced synergistic treatment

[0064] Test material: Poplar fast-growing wood (500×50×20mm length×width×thickness)

[0065] Put the enhanced and synergistic treatment solution 5 in a thick plastic bag, put the poplar fast-growing wood sample until submerged, vacuumize the plastic seal, and then place it in an ultra-high pressure equipment, soak it for 30min under the condition of 100-200MPa, and dry it to constant temperature at 103°C. Heavy, soak for 40min under the condition of 100-200MPa, take it out and put it in an oven for 1 hour to cure at high temperature.

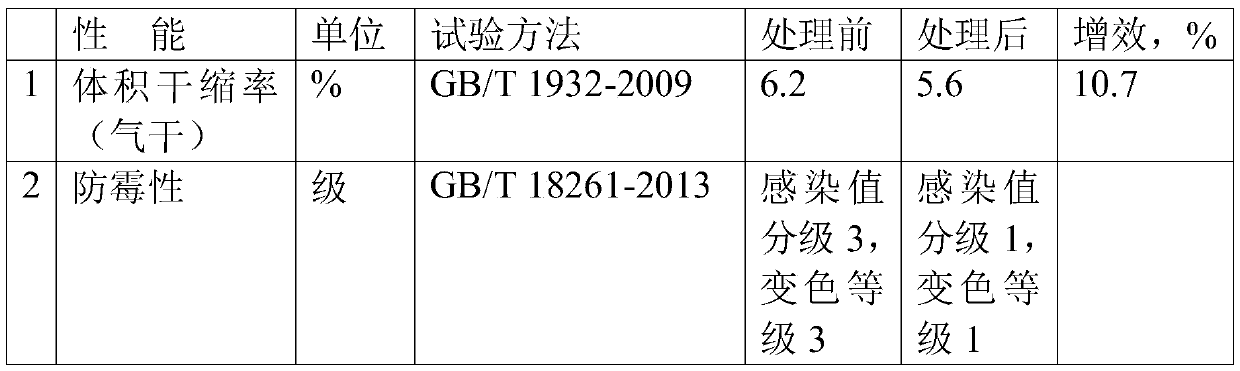

[0066] The performance test results of poplar fast-growing wood before and after treatment are shown in Table 3:

[0067] table 3

[0068]

[0069] It can be seen that after treatment, the hardness and compressive strength are enhanced, the volume shrinkage rate is reduced and increased, and the anti-corrosion performance is obviously improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com