Lock type self-repairing polymer, preparation method and application thereof

A self-healing, polymer technology, which is applied in the field of lock-type self-healing polymers and its preparation, can solve the problems of cumbersome synthesis methods, and achieve the effects of simple repair methods, increased polymerization flexibility, and high repair efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

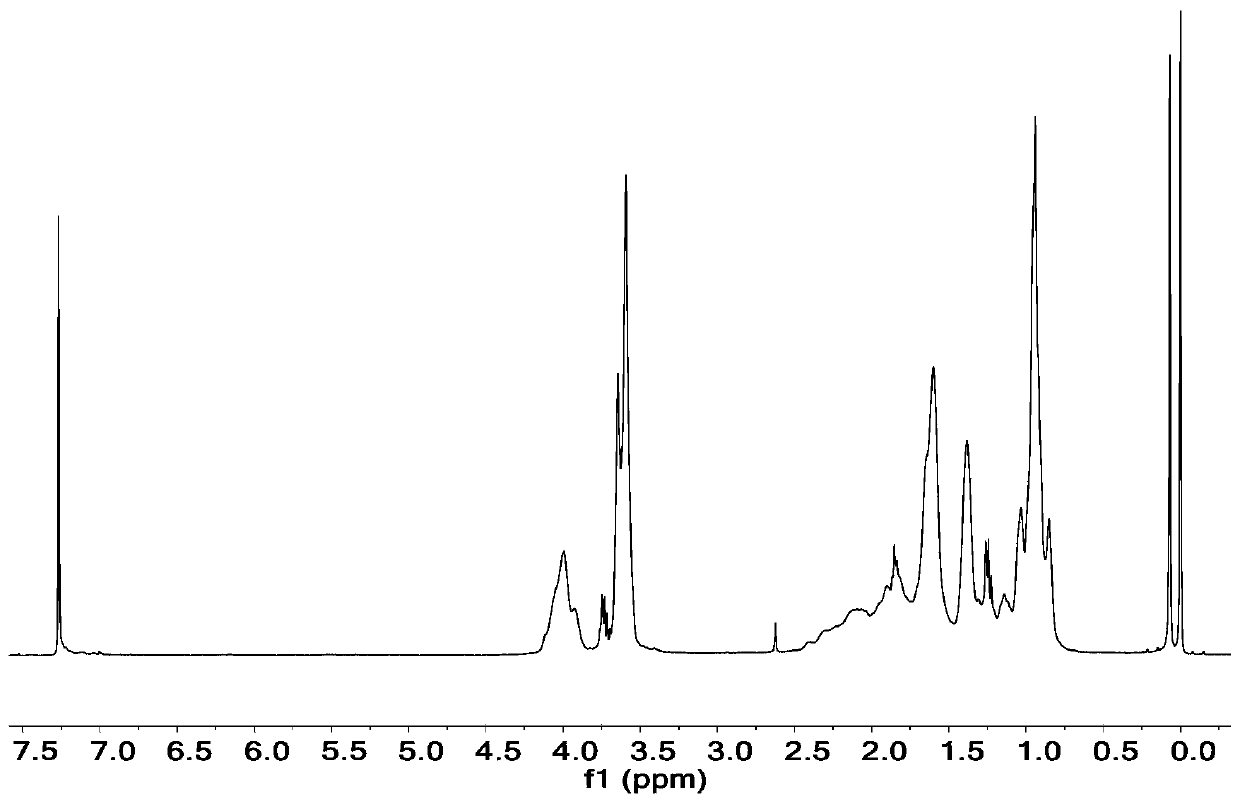

Image

Examples

Embodiment 1

[0038] A lock-type self-healing polymer obtained by polymerization of methyl methacrylate (PMMA) and butyl acrylate (BA). The name of the polymer is PMMA-co-PBA.

[0039] The preparation method of PMMA-co-PBA comprises the following steps:

[0040] Dissolve 5.05g MMA, 4.30g BA (molar mass ratio is 6:4) and 0.0936g BPO in 5mL toluene and react in an oil bath at 120°C for 12h. After the reaction is completed, add a certain amount of 5mL toluene, and then add a large amount of The product was precipitated by isopropanol, then filtered with suction, washed with isopropanol, and dried in an oven at 60°C to obtain PMMA-co-PBA.

Embodiment 2

[0042] A lock-type self-healing polymer obtained by polymerization of methyl methacrylate (PMMA) and butyl acrylate (BA). The name of the polymer is PMMA-co-PBA.

[0043] The preparation method of PMMA-co-PBA comprises the following steps:

[0044] Dissolve 5.05g MMA, 4.30g BA (molar mass ratio is 6:4) and 0.0936g BPO in 5mL toluene and react in an oil bath at 100°C for 12h. After the reaction is completed, add a certain amount of 5mL toluene, and then add a large amount of The product was precipitated by isopropanol, then filtered with suction, washed with isopropanol, and dried in an oven at 60°C to obtain PMMA-co-PBA.

Embodiment 3

[0046] A lock-type self-healing polymer obtained by polymerization of methyl methacrylate (PMMA) and butyl acrylate (BA). The name of the polymer is PMMA-co-PBA.

[0047] The preparation method of PMMA-co-PBA comprises the following steps:

[0048] Dissolve 5.05g MMA, 4.30g BA (molar mass ratio is 6:4) and 0.0936g BPO in 5mL toluene and react in an oil bath at 120°C for 8h. After the reaction is completed, add a certain amount of 5mL toluene, and then add a large amount of The product was precipitated by isopropanol, then filtered with suction, washed with isopropanol, and dried in an oven at 60°C to obtain PMMA-co-PBA.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com