High-barrier corrosion-resistant lithium battery packaging film and preparation method thereof

A packaging film and corrosion-resistant technology, which is applied in packaging, packaging paper, transportation and packaging, etc., can solve the problems of lithium battery corrosion and poor corrosion resistance, so as to improve corrosion resistance, improve electrochemical performance, and improve self-efficacy. The effect of discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to understand the technical scheme of the present invention more intuitively and completely, the non-restrictive feature descriptions are now carried out in conjunction with the accompanying drawings of the present invention as follows:

[0032] Such as figure 1 As shown, the barrier and corrosion-resistant lithium battery packaging film includes nylon layer 1, aluminum foil layer 3 and heat seal layer 6, and it also includes outer graphene layer 2, inner graphene layer 4 and silicone rubber layer 5, nylon layer 1, The outer graphene layer 2, the aluminum foil layer 3, the inner graphene layer 4, the silicone rubber layer 5 and the heat-sealing layer 6 are distributed sequentially from outside to inside.

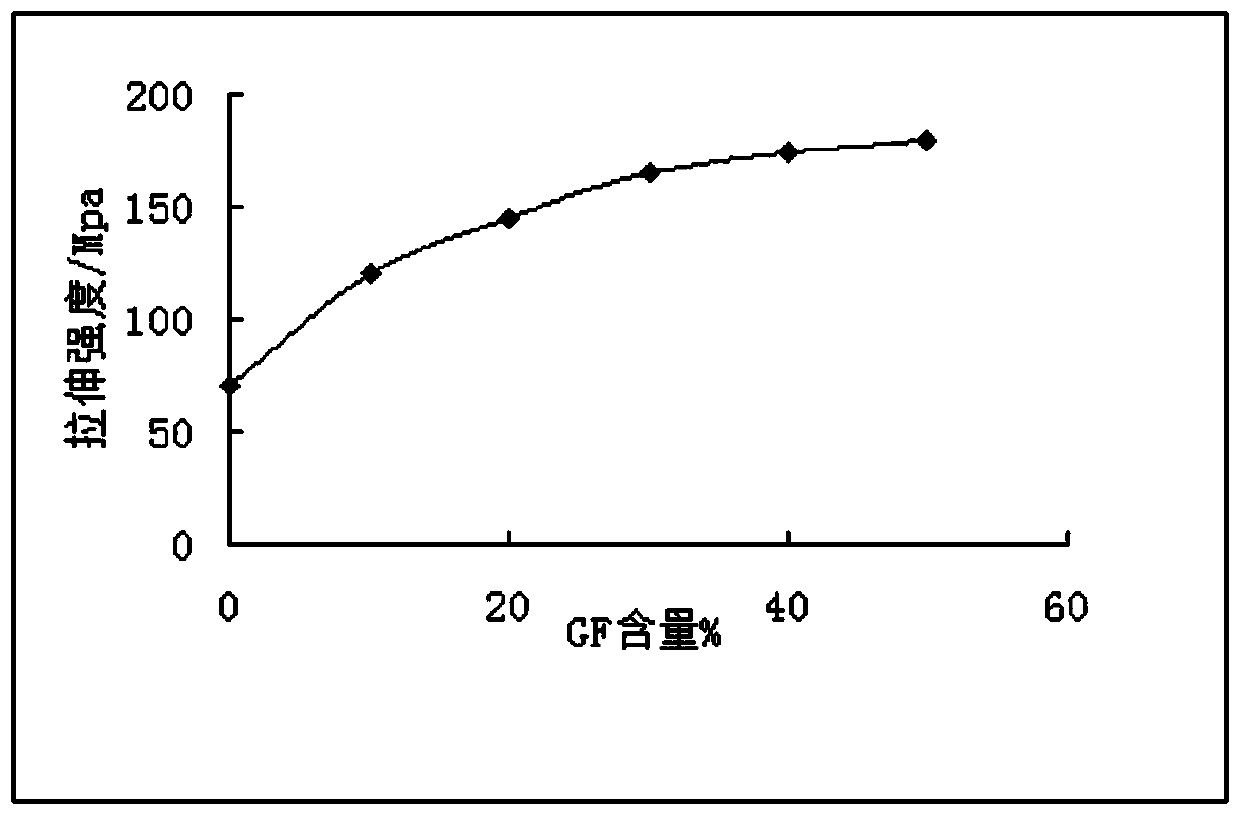

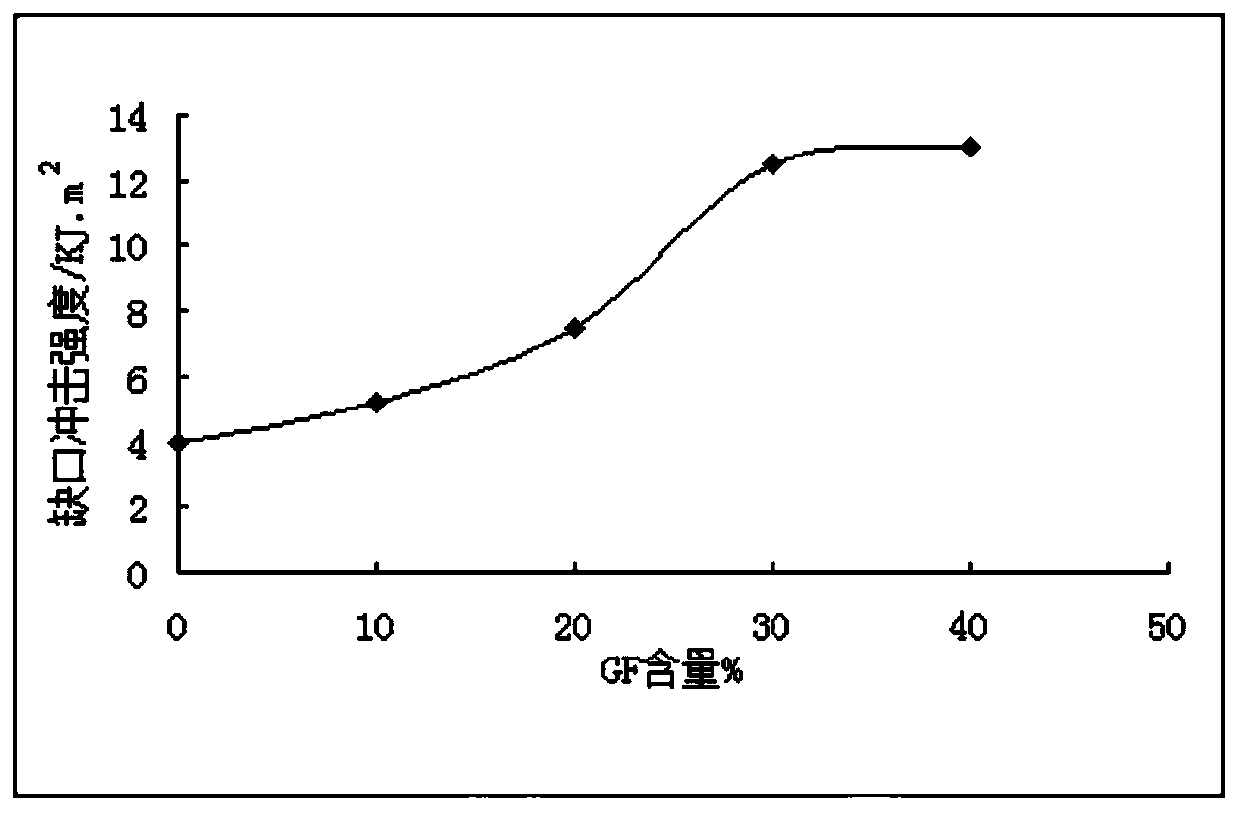

[0033] Nylon layer 1 is composed of the following raw materials in mass percentage: MXD6 57%, glass fiber 30%, LLD PE-g-MAH 9.5%, nano silicon dioxide 3%, silane coupling agent 0.3%, hydroquinone 0.2% ;

[0034] The heat-sealing layer 6 is made up of the fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com