A kind of ablation-resistant wave-absorbing anti-slip and wear-resistant composite coating and preparation method thereof

A composite coating, ablation-resistant technology, used in coatings, anti-corrosion coatings, fire-retardant coatings, etc., can solve the problems of lack of high-temperature ablation resistance and radar stealth performance, to improve anti-yellowing and degradation, The effect of improving service life and bonding strength between layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] A method for preparing an ablation-resistant wave-absorbing anti-slip and wear-resistant composite coating, comprising an anti-corrosion bottom layer, an ablation-resistant wave-absorbing sandwich layer, an anti-slip and wear-resistant layer, and an aging-resistant surface layer, specifically comprising the following steps:

[0052] (1) Preparation of anti-corrosion bottom layer: polish the base material or sandblast it to Sa2.5 level and above, clean it until the surface is free of oil, clean and dry it for use, and apply anti-corrosion evenly by spraying or brushing Primer 2-4 times, dry film thickness 50-150μm;

[0053] (2) Preparation of ablation-resistant wave-absorbing sandwich layer:

[0054] ①Preparation of the first layer of ablation-resistant layer: in parts by mass, weigh 40-60 parts of high-temperature resistant resin, 35-70 parts of ablation-resistant filler, 5-15 parts of flame-retardant filler and 4-40 parts of solvent in the ingredients In the vat, stir...

Embodiment 1

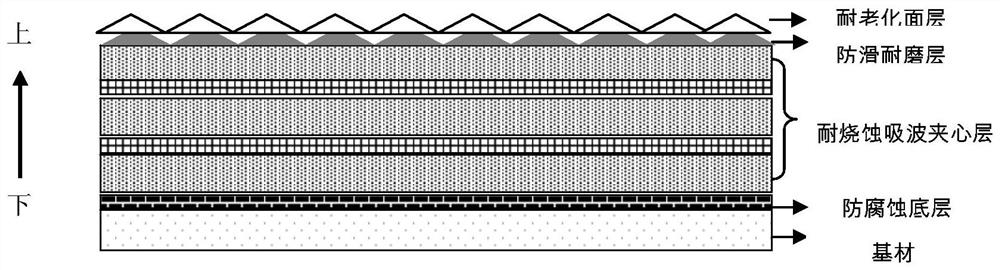

[0075] An ablation-resistant wave-absorbing anti-slip and wear-resistant composite coating, the composite coating includes an anti-corrosion bottom layer, an ablation-resistant wave-absorbing sandwich layer, an anti-slip wear-resistant layer, and an aging-resistant surface layer arranged sequentially from bottom to top; wherein, The anti-corrosion bottom layer is coated on the surface of the substrate. The ablation-resistant and wave-absorbing sandwich layer is a five-layer sandwich structure composed of three layers of ablation-resistant layers and two layers of wave-absorbing stealth layers. The intermediate surface is coated with a wave-absorbing stealth layer, and the lowest layer of ablation-resistant layer is coated on the surface of the anti-corrosion bottom layer. The structure of the composite coating is shown in figure 1 .

[0076] A method for preparing an ablation-resistant wave-absorbing anti-slip and wear-resistant composite coating, comprising an anti-corrosion ...

Embodiment 2

[0089] An ablation-resistant wave-absorbing anti-slip and wear-resistant composite coating, the composite coating includes an anti-corrosion bottom layer, an ablation-resistant wave-absorbing sandwich layer, an anti-slip wear-resistant layer, and an aging-resistant surface layer arranged sequentially from bottom to top; wherein, The anti-corrosion bottom layer is coated on the surface of the substrate. The ablation-resistant and wave-absorbing sandwich layer is a five-layer sandwich structure composed of three layers of ablation-resistant layers and two layers of wave-absorbing stealth layers. The intermediate surface is coated with a wave-absorbing stealth layer, and the lowest layer of ablation-resistant layer is coated on the surface of the anti-corrosion bottom layer. The structure of the composite coating is shown in figure 1 .

[0090] A method for preparing an ablation-resistant wave-absorbing anti-slip and wear-resistant composite coating, comprising an anti-corrosion ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com