Pretreatment method of 2-alkylanthraquinone working solution and production method of hydrogen peroxide

A technology of alkyl anthraquinone and pretreatment, applied in chemical instruments and methods, peroxide/peroxyhydrate/peroxyacid/superoxide/ozonide, inorganic chemistry, etc., can solve 2-alkyl Anthraquinone working solution contains impurities, which affect process operation and product indicators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

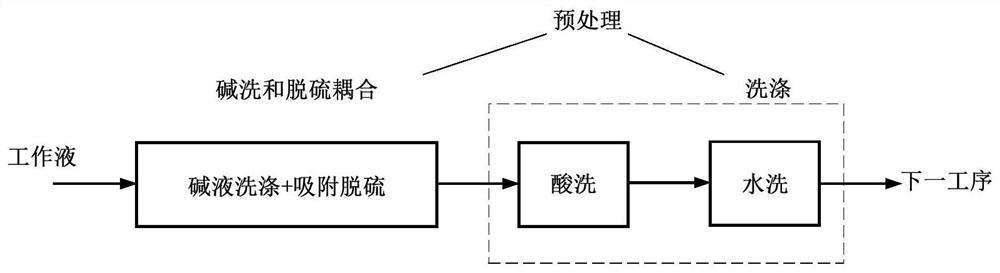

Method used

Image

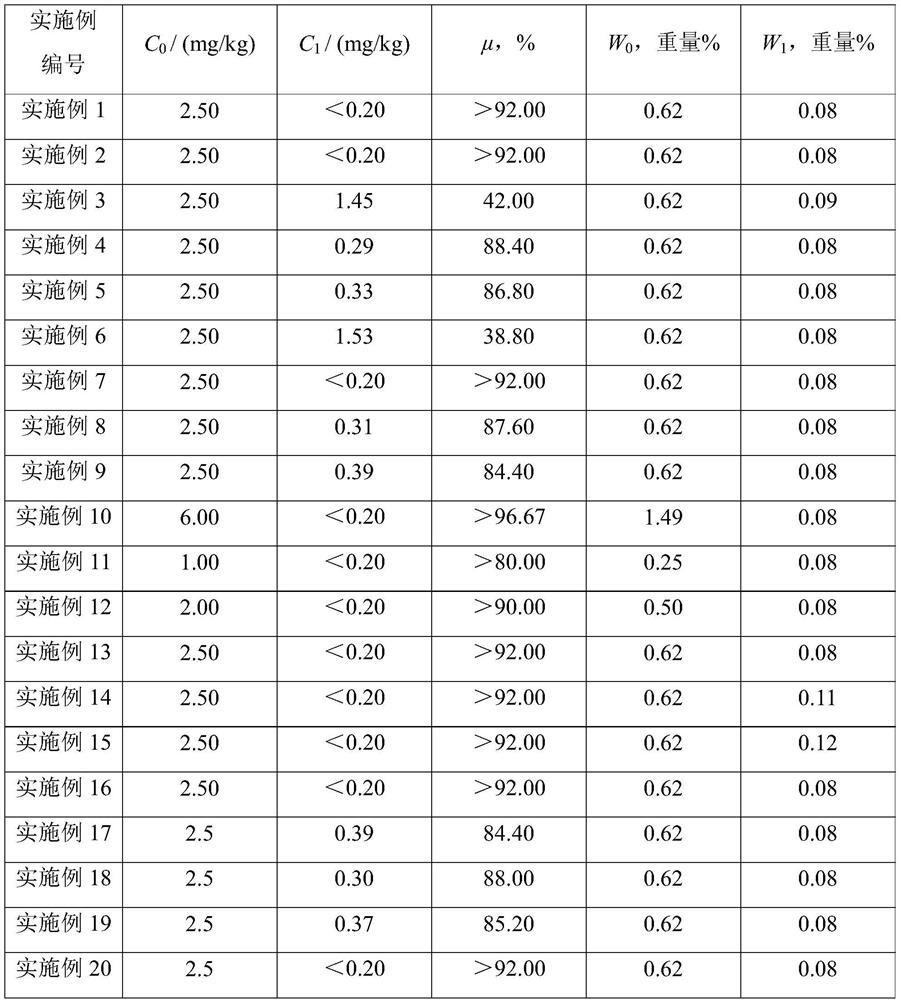

Examples

preparation example Construction

[0021] According to the present invention, except that the composition of the amorphous alloy is selected according to the present invention, the preparation method of the amorphous alloy can refer to conventional methods in the art. Preferably, the preparation method of the amorphous alloy comprises: mixing nickel in the above content range and one or more other metals selected from the group consisting of aluminum, iron, chromium, copper, zinc, molybdenum and cobalt, preferably The mixture of nickel, aluminum and one or more other metals selected from iron, chromium, copper, zinc, molybdenum and cobalt in the above content range is alloyed in vacuum and at a temperature higher than their melting point, and then used This alloy is quickly quenched by the vacuum quenching method, and the rapid quenching condition is that the copper roll rotating speed is 600-1000 rpm (the specific embodiment is preferably 800 rpm), and the injection pressure is 0.05-0.1MPa to form a scaly strip...

preparation example 1

[0053] This preparation example is used to illustrate the preparation of the amorphous alloy Ni-Fe-Al adsorbent.

[0054] Add 25 grams of nickel, 50 grams of aluminum, and 15 grams of iron into the quartz tube, heat it in a high-frequency furnace to above 1300 ° C to melt it, and make it alloyed, and then the alloy liquid is sprayed from the nozzle under the quartz tube to On the copper roller with a rotating speed of 800 rpm (spray pressure 0.08MPa), cooling water is passed into the copper roller, and the alloy liquid is thrown out along the tangent of the copper roller after rapid cooling to form scale-like strips, which are ground Until the particle diameter is 60-80 microns, a master alloy is obtained. Adopt X-ray powder diffractometer (Japanese science D / MAX-2500 type X-ray diffractometer, Cu Kα ray, electric current is 100mA, the same below) carries out XRD analysis to obtained master alloy, and the obtained XRD pattern shows that in 2θ angle A diffuse peak appears at 4...

preparation example 2-6

[0057] The amorphous alloy adsorbent was prepared according to the method of Preparation Example 1, the difference was the amount and composition of the metal, and the composition of the prepared adsorbent was shown in Table 1.

[0058] Table 1

[0059]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com