Analysis and monitoring method for large-range non-stationary transient continuous process

A non-stationary, large-scale technology, applied in the direction of program control, total factory control, total factory control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

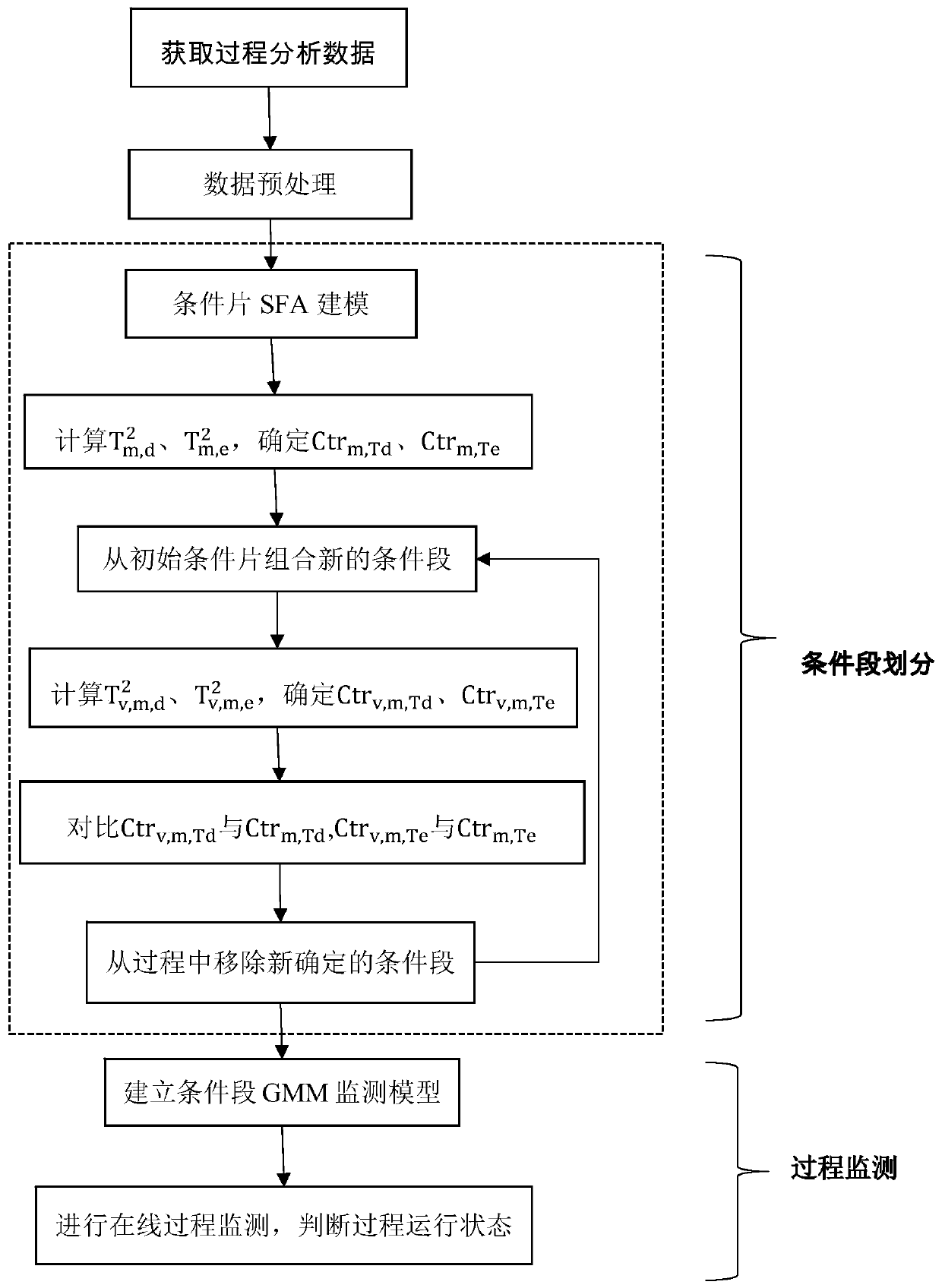

Method used

Image

Examples

Embodiment Construction

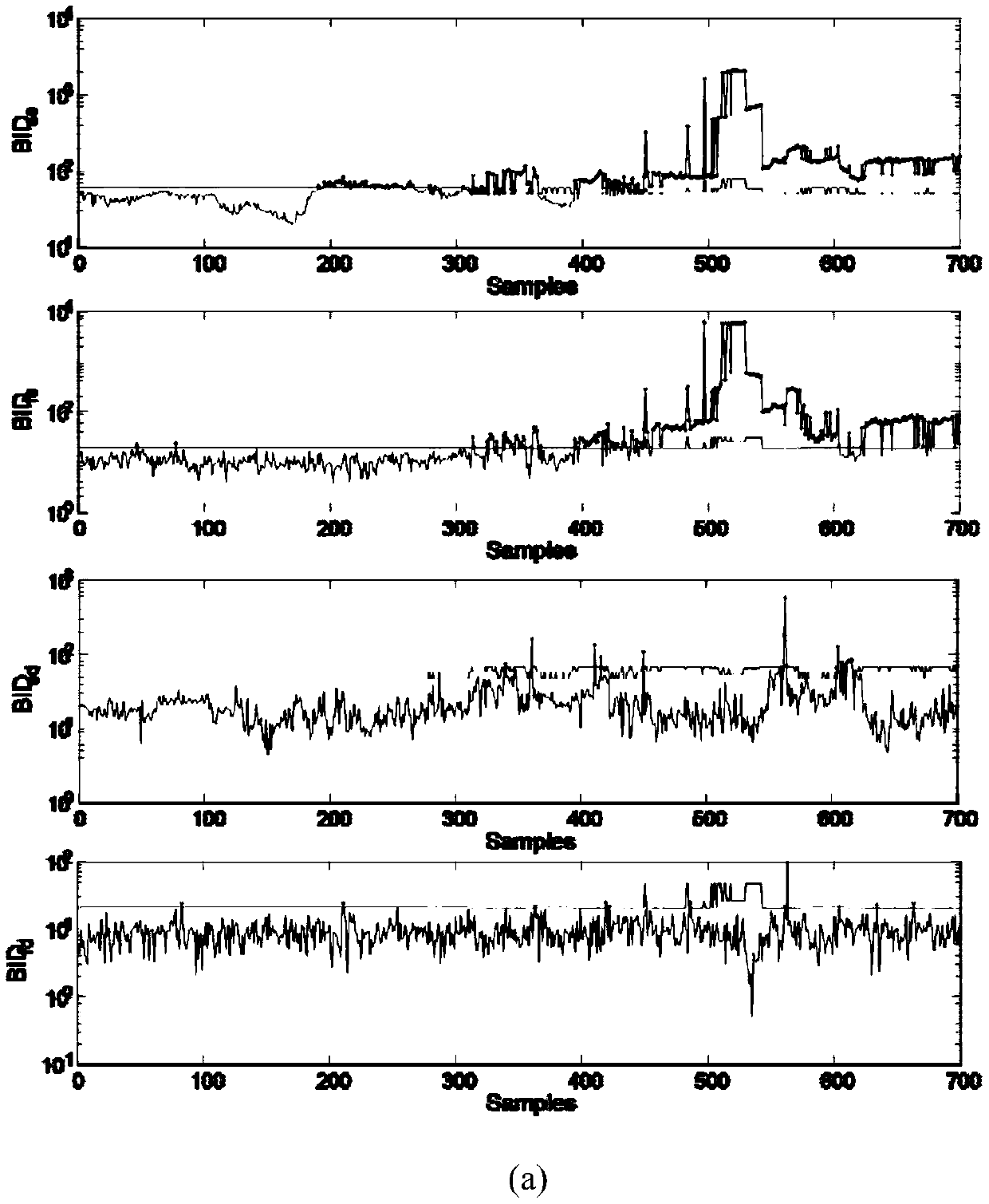

[0091] The present invention will be further described below in conjunction with the accompanying drawings and specific examples.

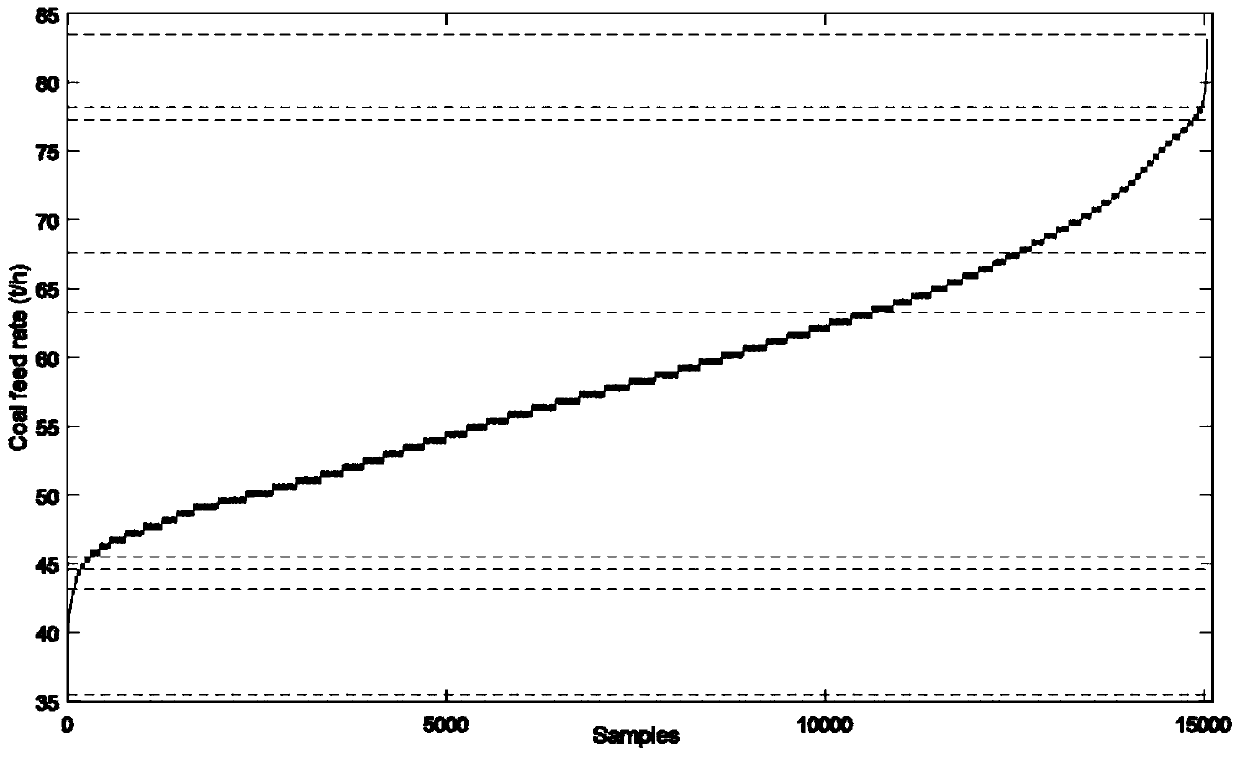

[0092] The 1000MW ultra-supercritical unit is a highly complex industrial process with time-varying, dynamic characteristics and non-stationarity. The coal mill is one of the important auxiliary machines of the ultra-supercritical unit of the thermal power plant. Its working principle is: the raw coal enters the rotating grinding bowl through the central coal drop pipe connected to the coal feeder. After the raw coal falls into the grinding bowl, it moves radially outward to the grinding bowl ring under the action of centrifugal force. A bed of coal is formed on the mill bowl. The coal passes under the grinding roller device that can rotate around the shaft. At this time, the grinding force generated by the spring-loaded device is applied to the coal through the rotating grinding roller, and the coal is ground into powder between the grinding bow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com