A kind of low temperature production liquid epoxy resin method

A technology of liquid epoxy resin and low temperature, applied in the field of production of liquid epoxy resin, can solve the problems of increased degree of polymerization of epoxy resin resin, severe local reaction, increase of aging resin, etc., to achieve less generation of aging resin, low total chlorine, The effect of less side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

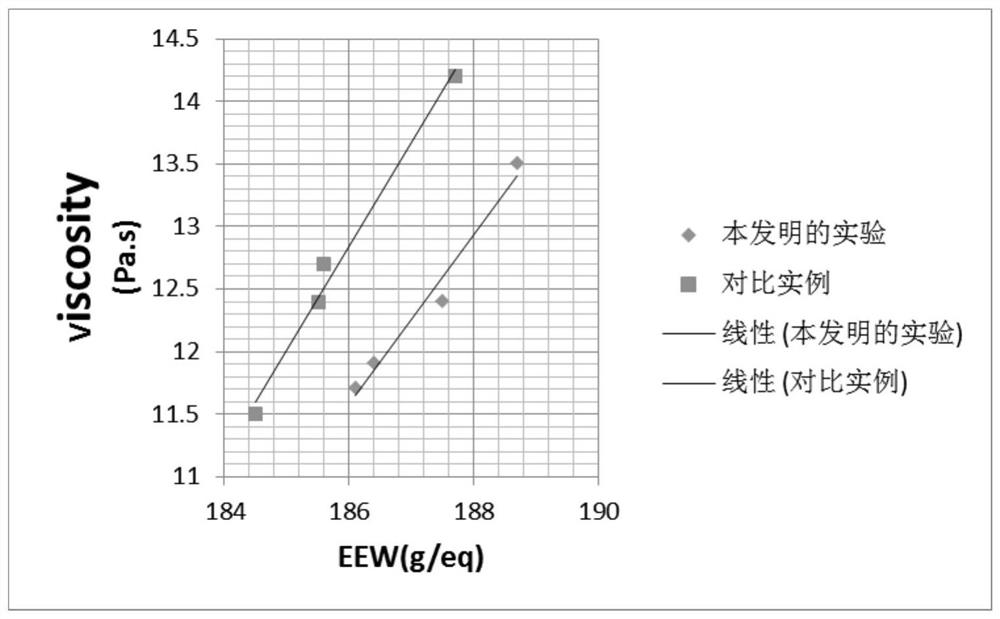

Image

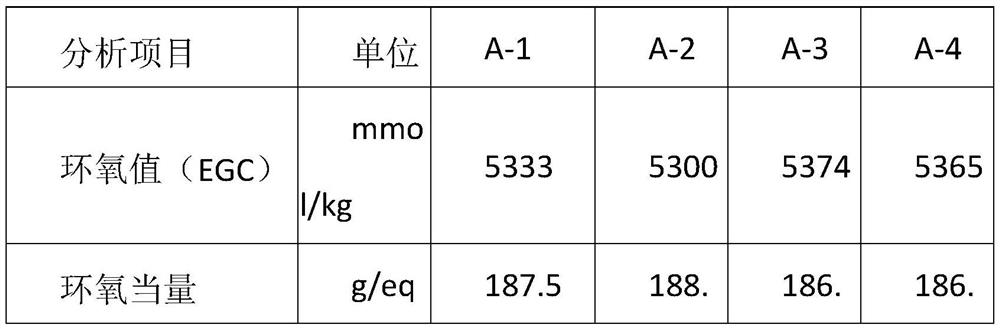

Examples

Embodiment 1

[0028]

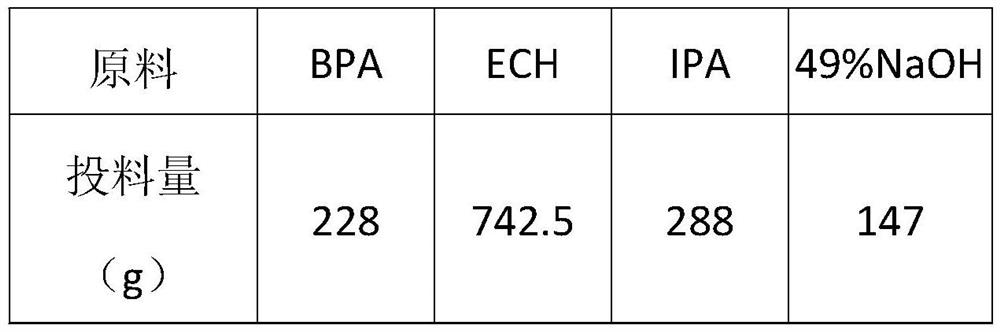

[0029] Table 1

[0030] Feeding: feed according to the raw materials shown in Table 1 and the feeding amount, drop into ECH, BPA, IPA and be warmed to a temperature of 30°C,

[0031] Reaction: 49% NaOH is added with water to make 24% NaOH, and it is dropped into the reaction kettle at 30°C for 90 minutes. The whole process is exothermic. When 24% NaOH is added dropwise, the temperature of the system gradually rises. When the alkali is added, the temperature of the system rises to about 60-70°C. After standing for 30 minutes, the system is layered, and the upper layer is the crude resin, ECH, IPA. ; The lower layer is water, salt, and a small amount of IPA. The brine is separated and removed, and the ECH / IPA in the upper oil phase enters the desolvation recovery unit,

[0032] Precipitation, purification and purification: the material containing ECH / solvent crude resin is subjected to negative pressure removal after ECH / solvent precipitation is completed, the crud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com