A kind of high-performance copper alloy and its powder preparation method

A technology for powder preparation and copper alloys, applied in the field of copper alloys and powder metallurgy materials, can solve the problem that the alloy cannot meet high strength and high electrical conductivity at the same time, the coarse primary second phase has no obvious improvement effect, and it is difficult to refine the primary phase, etc. problems, to achieve uniform composition and microstructure, to achieve effective regulation, and the effect of inhibiting the formation of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Embodiment 1: Alloy A and powder preparation thereof

[0054] According to the nominal composition of alloy A in Table 1, alloy raw materials are prepared, and pure metals Cu, Cr, Zr and M (M is RE (La: Ce: Yb (mass ratio) = 1:3:1) are prepared in a water-cooled copper crucible magnetic levitation melting furnace ), Mg, Ag, B mixture, its specific ratio is: RE:Mg:Ag:B (mass ratio) = 3:1:2:1) and other alloy raw materials for vacuum melting, the vacuum degree is 5.0×10 -1 Pa, using argon protection; after the raw materials are melted and completely alloyed, adjust the melt temperature to about 1600°C, and then use argon to atomize to prepare powder, the atomization pressure is 3.5MPa~3.6MPa; The copper alloy powders were sieved in a vacuum glove box and stored in vacuum packaging. The powder extraction rate of fine powder is 90%.

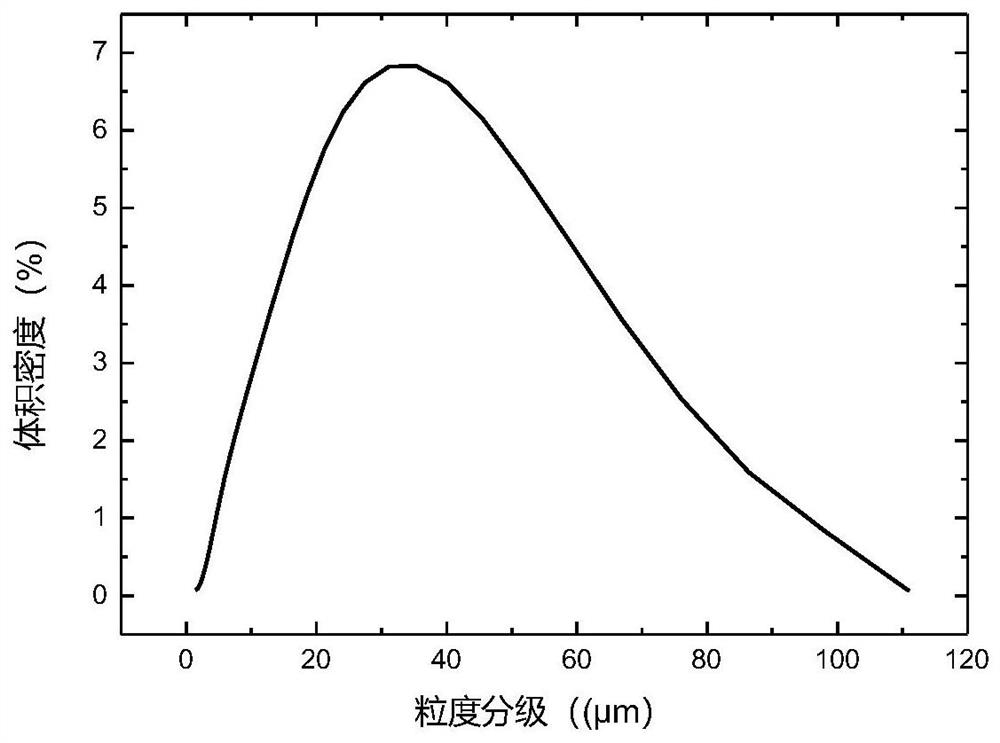

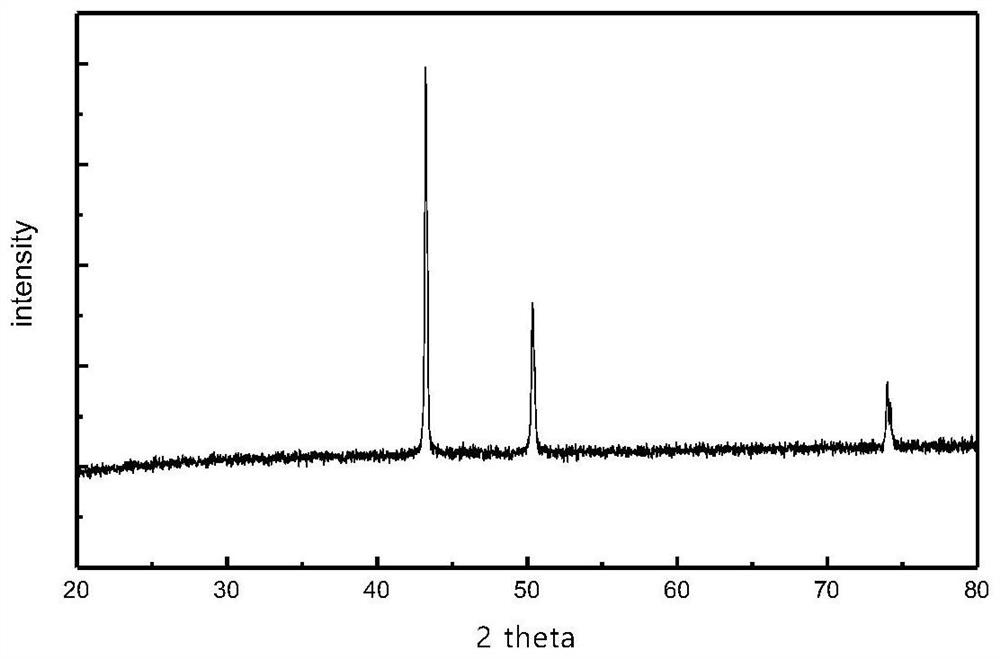

[0055] The prepared powder chemical composition analysis results are shown in Table 1, and its particle size distribution is shown in Table...

Embodiment 2

[0056] Embodiment 2: Alloy B and its powder preparation

[0057] According to the nominal composition of alloy B in Table 1, pure metals are taken, and raw materials Cu, Cr, Zr and M (M is a mixture of RE (La:Ce:Yb (mass ratio)=1:3:1), Mg, Ag, Si , and its specific ratio is: RE:Mg:Ag:Si (mass ratio) = 3:1:2:1) is melted in a vacuum induction melting furnace with a vacuum degree of 4.0×10 -1 Pa, protected by argon; after the raw materials are melted and completely alloyed, the melt temperature is adjusted to 1400°C, and then argon is used for atomization to prepare powder. The atomization pressure is 3.5MPa-3.6MPa; the copper alloy powder prepared by atomization is screened in a vacuum glove box and stored in vacuum packaging. The powder yield of fine powder is 84%.

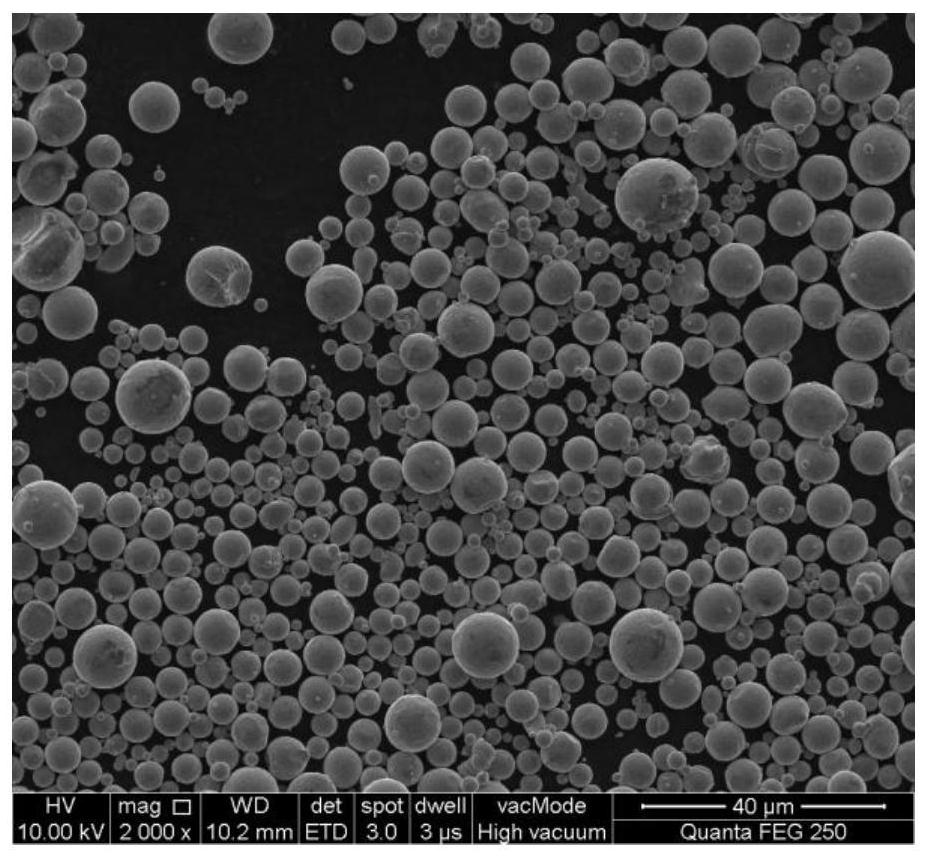

[0058] The prepared powder chemical composition analysis results are shown in Table 1, and the powder morphology is shown in Table 1. Figure 5 , good sphericity and uniform particle size distribution. Powder ...

Embodiment 3

[0059] Embodiment 3: Alloy C and its powder preparation

[0060] According to the nominal composition of alloy C in Table 1, pure metal is taken, and the raw materials Cu, Cr, Zr and M, M is a mixture of (La:Ce:Yb=1:3:1), Mg, Ag, Ga, and its specific ratio For RE:Mg:Ag:Ga (mass ratio) = 3:1:2:1), it is melted in the water-cooled copper crucible of the magnetic levitation atomization equipment, and the vacuum degree is 5×10 -1 Pa, protected by argon gas; after the raw materials are melted and completely alloyed, the melt temperature is adjusted to about 1500°C, and then argon gas is used for atomization to prepare powder. The atomization pressure is 3.5MPa-3.6MPa; the copper alloy powder prepared by atomization is screened in a vacuum glove box and stored in vacuum packaging. The powder yield of fine powder is 86%.

[0061] The prepared powder chemical composition analysis results are shown in Table 1, and the powder morphology is shown in Table 1. Figure 7 , good sphericit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com