Near-infrared fluorescent powder and luminescent device containing near-infrared fluorescent powder

A technology for light-emitting devices and phosphors, which can be applied to light-emitting materials, semiconductor devices, chemical instruments and methods, etc., can solve the problems of poor stability and low light-emitting efficiency, and achieve the effects of avoiding high cost, improving light-emitting intensity and expanding the scope of application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The near-infrared fluorescent powder described in this embodiment, the compound composition formula that it comprises is Sc 0.98 GaO 3 :Cr 0.02 .

[0037] According to chemical formula Sc 0.98 GaO 3 :Cr 0.02 The stoichiometric ratio, accurately weighed Sc 2 o 3 , Ga 2 o 3 and Cr 2 o 3Mix evenly to obtain a mixture; calcinate the obtained mixture at 1400°C for 8 hours in a reducing atmosphere, and obtain a roasted product after cooling down; carry out post-treatments such as crushing, grinding, grading, and sieve washing on the obtained roasted product to obtain a near-infrared phosphor sample .

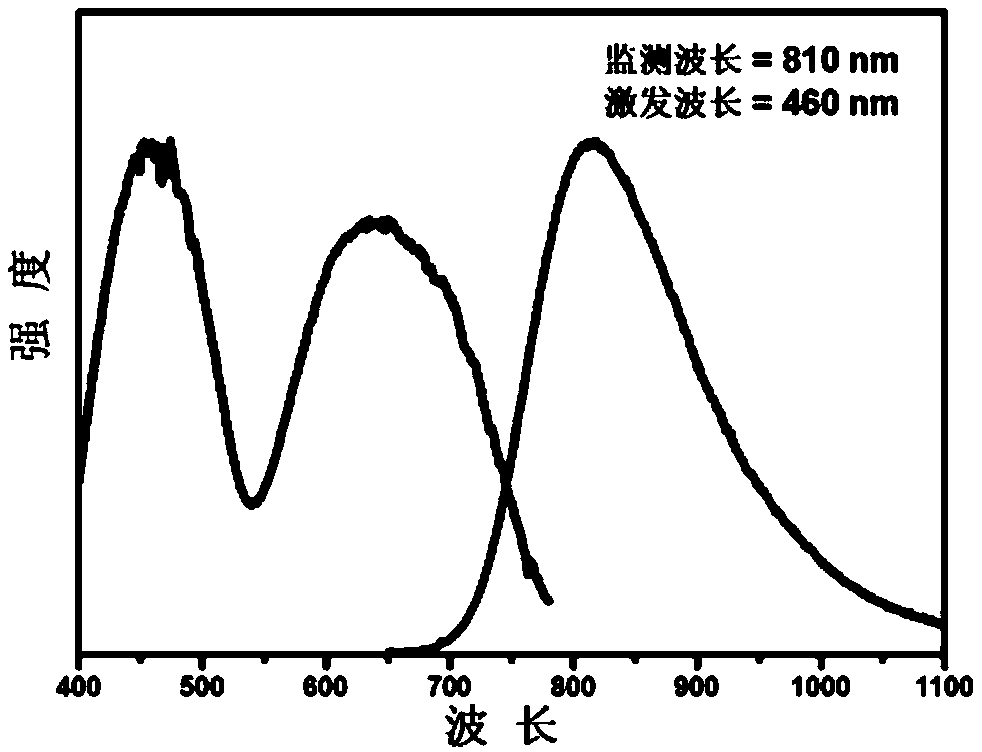

[0038] The resulting near-infrared luminescent material sample was subjected to an excitation test, and the excitation and emission spectra of the sample were obtained as shown in the attached figure 2 shown. It can be seen that the emission peak of the phosphor is located at 835nm, and the relative luminous intensity is 130.

Embodiment 2

[0040] The near-infrared fluorescent powder described in this embodiment, the compound composition formula that it comprises is Sc 0.98 Ga 0.3 B 0.7 o 3 :Cr 0.02 .

[0041] According to chemical formula Sc 0.98 Ga 0.3 B 0.7 o 3 :Cr 0.02 The stoichiometric ratio, accurately weighed Sc 2 o 3 , Ga 2 o 3 and Cr 2 o 3 Mix evenly; calcinate the obtained mixture at 1400°C for 8 hours in a reducing atmosphere, and obtain a roasted product after cooling down; carry out post-processing such as crushing, grinding, grading, and sieve washing on the obtained roasted product to obtain a near-infrared phosphor sample. It is determined that the emission peak of the phosphor is located at 826nm, and the relative luminous intensity is 150.

Embodiment 3-26

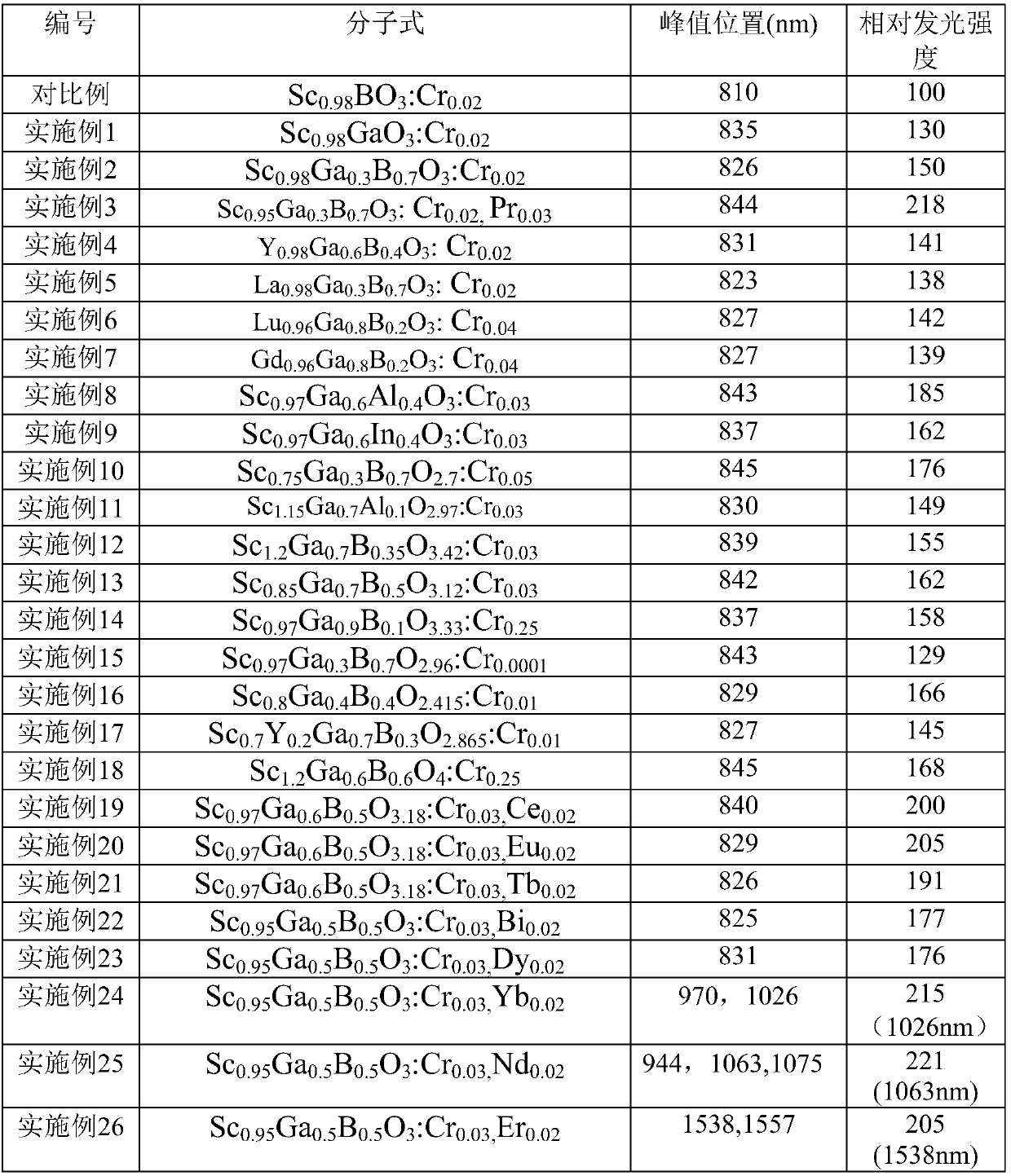

[0043] For the near-infrared phosphors described in Examples 3-26 and the light-emitting device containing the phosphors, their compound composition formulas are listed in Table 1 below, and the preparation method of the materials in each example is the same as that of Example 1. According to the chemical formula composition of the target compound in each embodiment, an appropriate amount of compound is selected for mixing, grinding, and roasting to obtain the desired near-infrared luminescent substance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Emission peak | aaaaa | aaaaa |

| Emission peak | aaaaa | aaaaa |

| Emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com