Etching solution composition and method for forming metal circuit

A composition and etching solution technology, applied in the field of display panels, can solve problems such as difficult etching, affecting the back-end process, and unfriendly environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

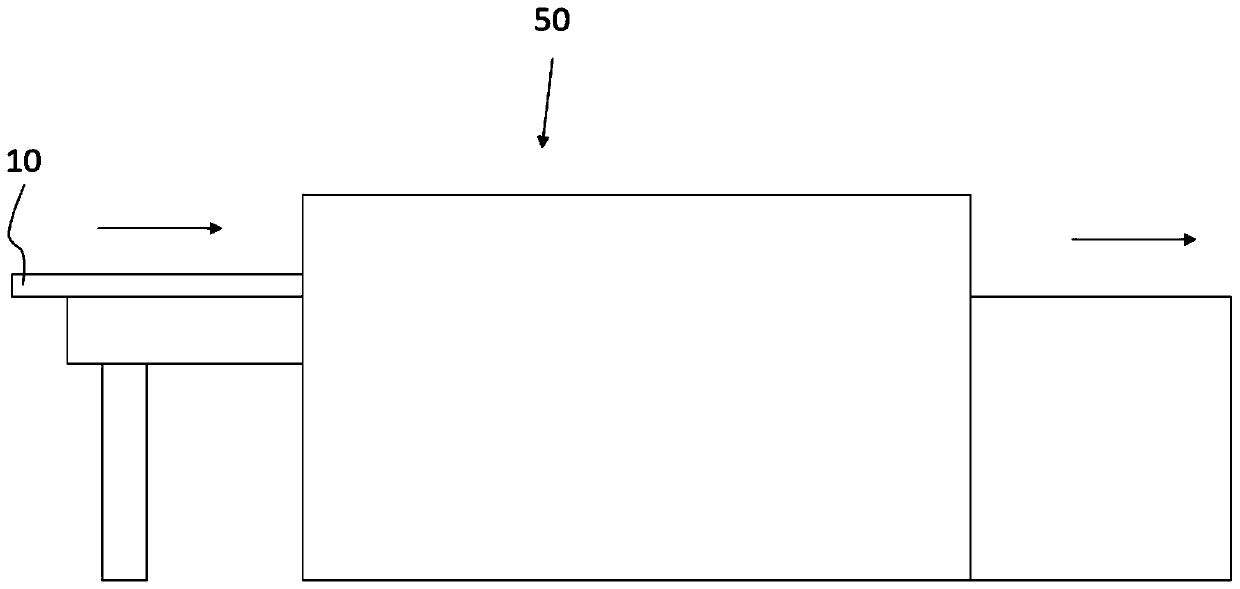

[0031] figure 1 Shown is a schematic diagram of the display panel 10 entering the etching machine 50 in this embodiment, the etching temperature of the etching machine 50 is set to 32°C, and the plate speed is 2m / min;

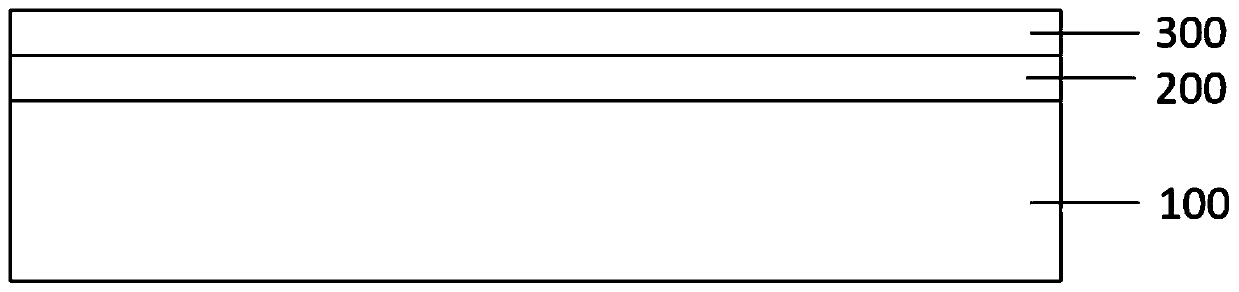

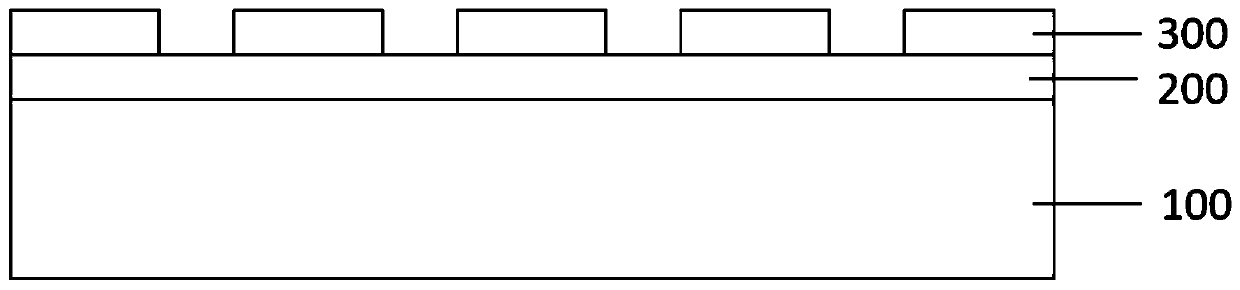

[0032] Figure 2a Shown is a schematic cross-sectional view of the display panel 10 of this embodiment, including a glass substrate 100, a copper / molybdenum-titanium (Cu / MoTi) alloy film layer 200 covering the glass substrate 100, and a copper / molybdenum-titanium (Cu / MoTi) alloy film layer 200, and a copper / molybdenum-titanium (Cu / MoTi) ) the photoresist layer 300 coated on the alloy film layer 200, after being exposed through a photomask and developed by a developer, as Figure 2b As shown, the area not covered by the photoresist layer 300 is the area to be etched.

[0033] The pH value of the etching solution composition used is 4.7, and the content is as shown in Table 1 below:

[0034]

[0035] Table I

[0036] image 3 Shown is a schematic diagram ...

Embodiment 2

[0039] figure 1 Shown is a schematic diagram of the display panel 10 entering the etching machine 50 in this embodiment, the etching temperature of the etching machine 50 is set at 34°C, and the plate speed is 1.8m / min;

[0040] Figure 2a Shown is a schematic cross-sectional view of the display panel 10 of this embodiment, including a glass substrate 100, a molybdenum-titanium / copper / molybdenum-titanium (MoTi / Cu / MoTi) alloy film layer 200 covering the glass substrate 100, and a molybdenum-titanium / molybdenum-titanium (MoTi / Cu / MoTi) alloy film layer 200, and The photoresist layer 300 coated on the copper / molybdenum-titanium (MoTi / Cu / MoTi) alloy film layer 200, after being exposed through a photomask and developed by a developer, as Figure 2b As shown, the area not covered by the photoresist layer 300 is the area to be etched.

[0041] The pH value of the used etching solution composition is 5.8, and the content is as shown in Table 2 below:

[0042]

[0043]

[0044]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com