Roller carrier shaft end sealing ring good in weather ability

A roller shaft and end sealing technology, which is applied in the direction of engine seals, rollers, engine components, etc., can solve the problems of poor sealing stability and unsatisfactory waterproof performance of sealing sleeves, and achieve improved heat resistance, good waterproof effect, The effect of improving weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

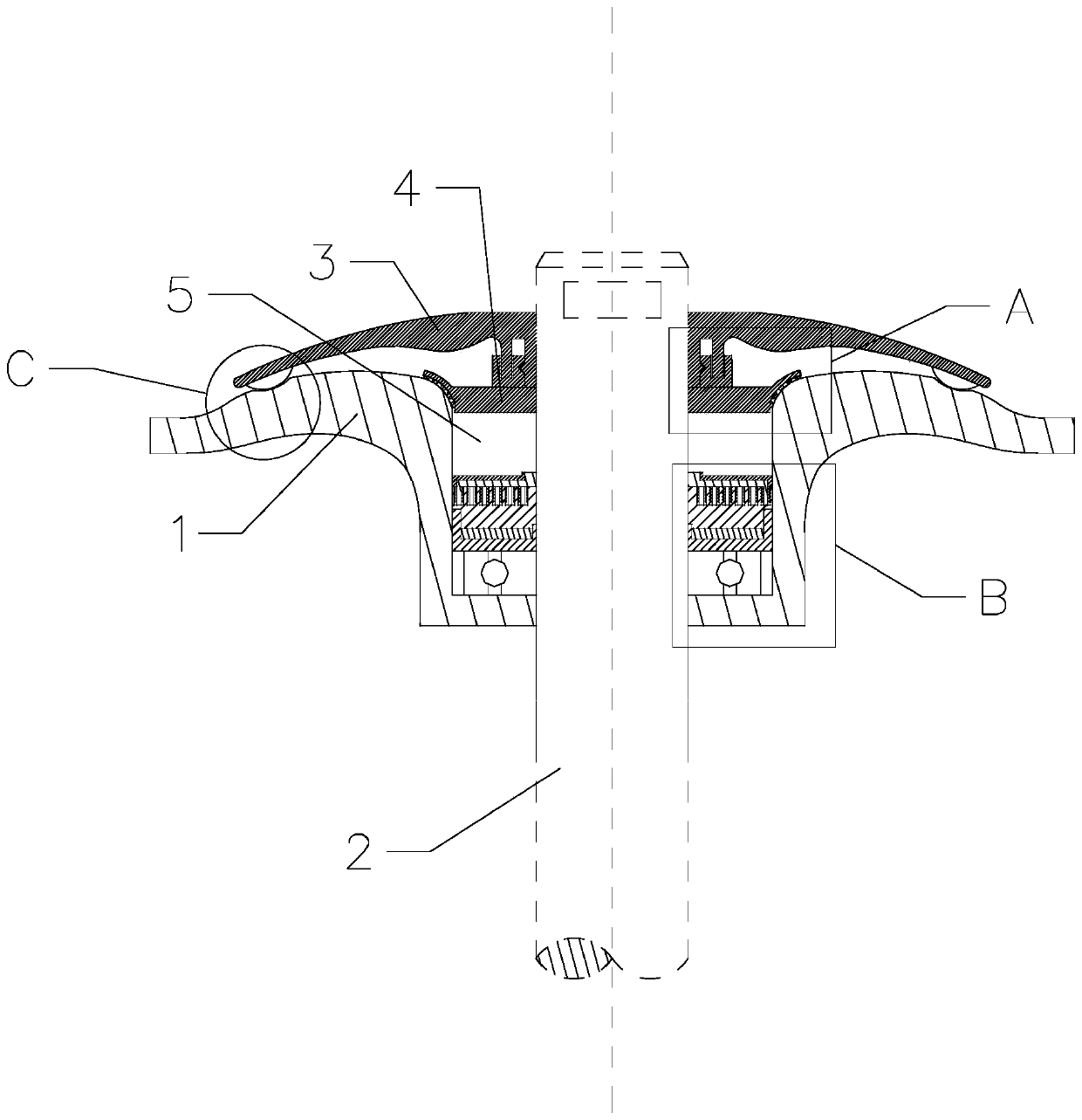

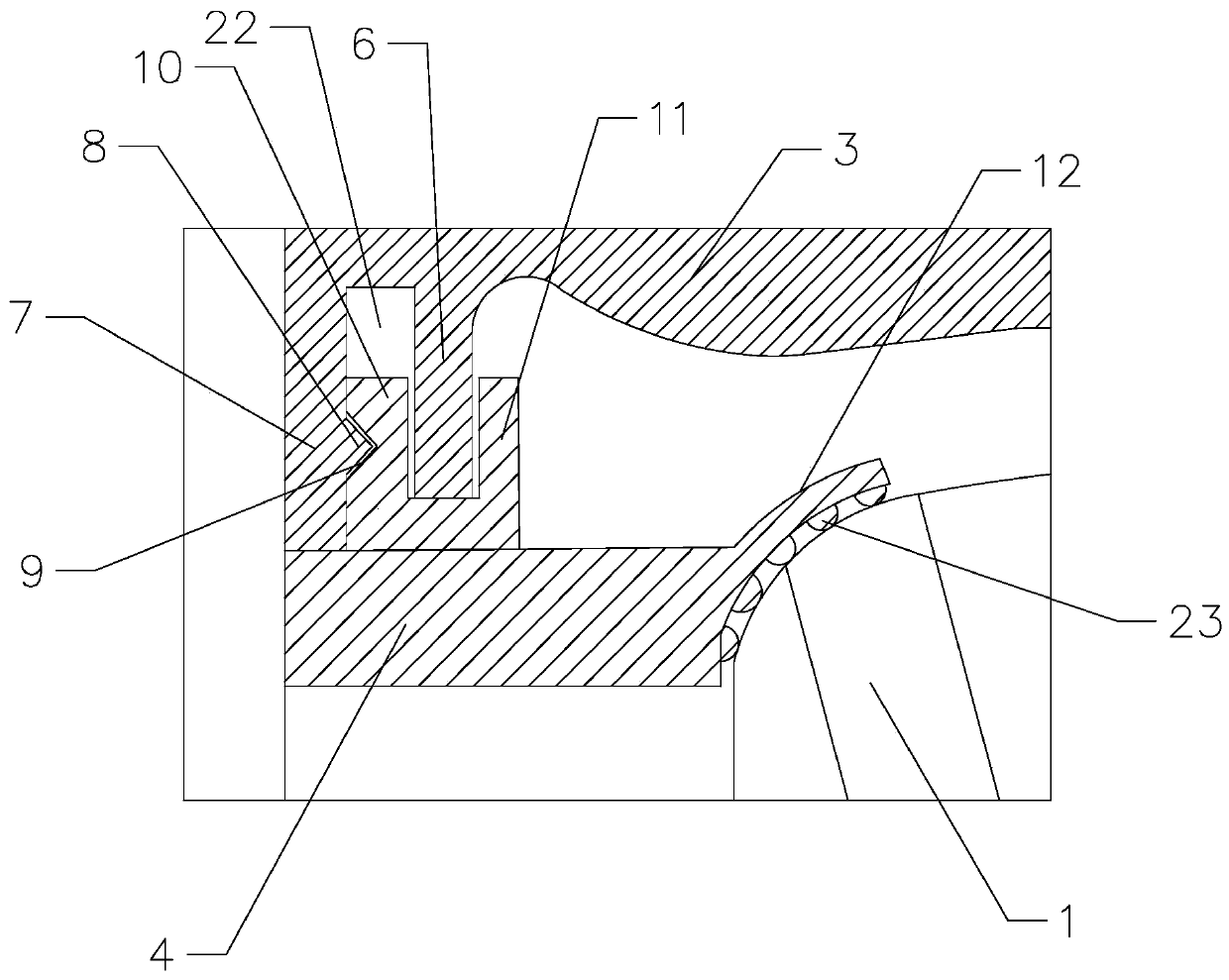

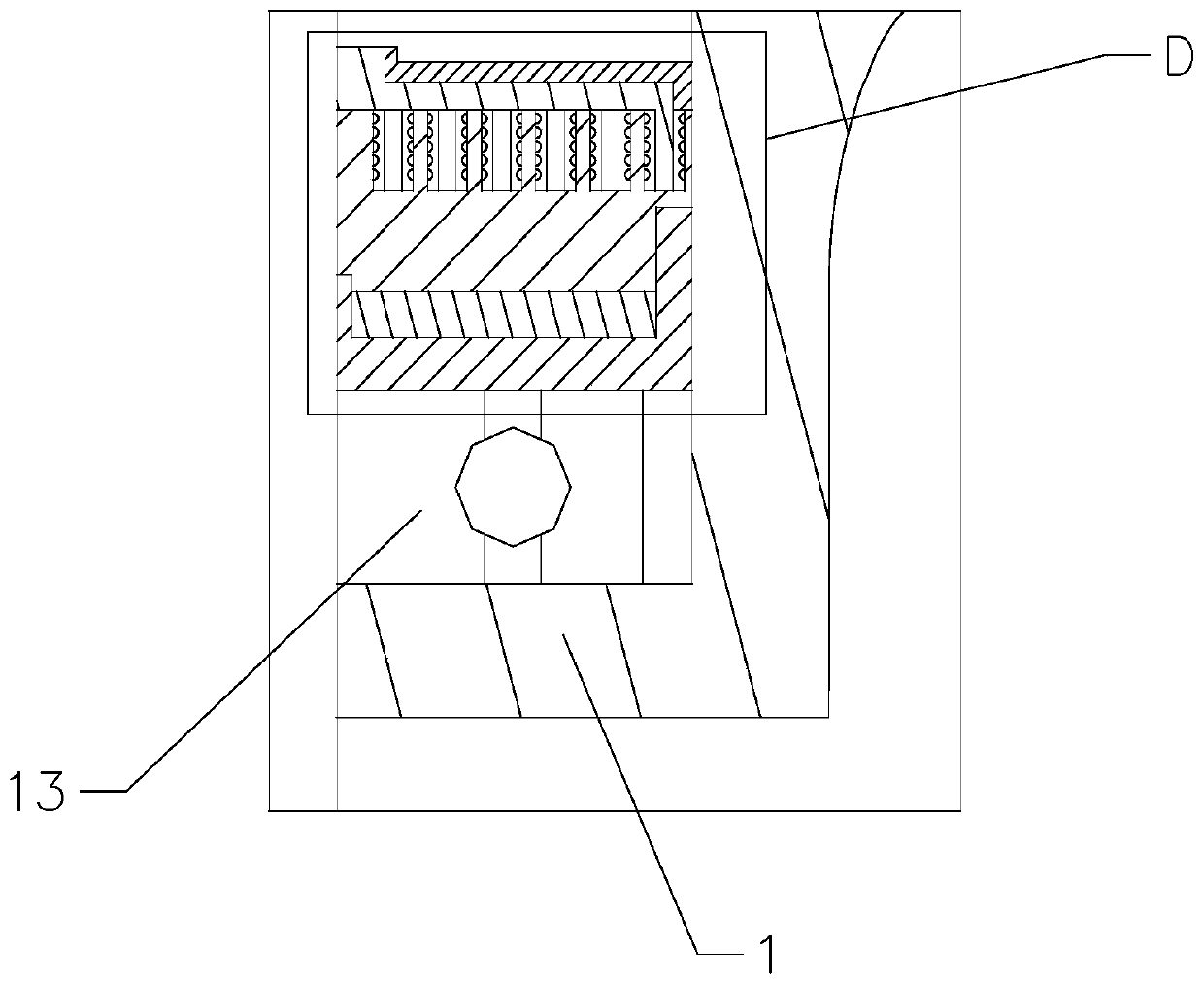

[0032] like Figure 1-5As shown, a sealing ring at the end of the idler shaft 2 with good weather resistance proposed by the embodiment of the present invention includes a bearing seat 1 and a sealing shaft that are sequentially sleeved on the shaft 2 from the inside to the outside with respect to the center point of the shaft 2. 2 bearings, mounting seat 14, gasket 15, inner cylinder 16, outer cylinder 18, inner sealing cover 4 and outer sealing cover 3, the bearing seat 1 is provided with a sealing cavity 5, and the mounting seat 14 is located in the sealing cavity 5, A gasket 15 is installed on the side of the mounting seat 14 away from the bearing seat 1, and a plurality of annular second slots 19 are provided on the side of the inner cylinder 16 close to the outer cylinder 18, and the outer cylinder 18 is close to the inner cylinder 16. One side is provided with a plurality of annular fourth pins 17, the fourth pins 17 are located in the second slot 19, the inner wall of ...

Embodiment 2

[0044] The difference between this embodiment and embodiment 1 is:

[0045] The raw materials of the outer cylinder 18 all include by weight: 80 parts of POM, 8 parts of styrene-butadiene rubber, 3 parts of carbon black N330, 5 parts of white carbon black, 1 part of nano-titanium dioxide, 25 parts of heat-resistant modifier, silane 4 parts of coupling agent KH-550, 9 parts of accelerator TMDT, 2 parts of zinc oxide, 5 parts of stearic acid, 4 parts of antioxidant RD, 9 parts of EPDM rubber, 4 parts of polyester fiber, heavy calcium carbonate 8 parts, graphite powder 3 parts, silicon carbide 9 parts.

[0046] In this embodiment, the heat-resistant modifier includes the following raw materials in parts by weight: 8 parts of carbamate, 5 parts of butyl acrylate, 2 parts of benzoyl peroxide, 6 parts of polypropylene, 4 parts of silane coupling agent KH-570, 9 parts of aluminum diethylphosphinate, 2 parts of aluminum polyphosphate, 8 parts of porcelain powder, 3 parts of nano alum...

Embodiment 3

[0052] The difference between this embodiment and embodiment 1 is:

[0053] The raw materials of the outer cylinder 18 all include by weight: 120 parts of POM, 4 parts of styrene-butadiene rubber, 9 parts of carbon black N330, 2 parts of white carbon black, 5 parts of nano titanium dioxide, 15 parts of heat-resistant modifier, silane 8 parts of coupling agent KH-550, 3 parts of accelerator TMDT, 6 parts of zinc oxide, 1 part of stearic acid, 8 parts of anti-aging agent RD, 4 parts of EPDM rubber, 8 parts of polyester fiber, 2 parts of heavy calcium carbonate parts, graphite powder 9 parts, silicon carbide 5 parts.

[0054] In this embodiment, the heat-resistant modifier includes the following raw materials in parts by weight: 12 parts of carbamate, 1 part of butyl acrylate, 5 parts of benzoyl peroxide, 3 parts of polypropylene, 8 parts of silane coupling agent KH-570, 3 parts of aluminum diethylphosphinate, 6 parts of aluminum polyphosphate, 4 parts of porcelain powder, 9 par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com