Switching control valve for state of aircraft cargo compartment fire extinguishing system

A fire-extinguishing system and conversion control technology, applied in multi-port valves, valve devices, mechanical equipment, etc., can solve the problems of lengthening fire-extinguishing pipelines, scrapping of flow control devices, and poor recycling capacity, etc. The effect of recycling rate and fire extinguishing safety guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Preferred embodiments of the present invention will be described in detail below. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention.

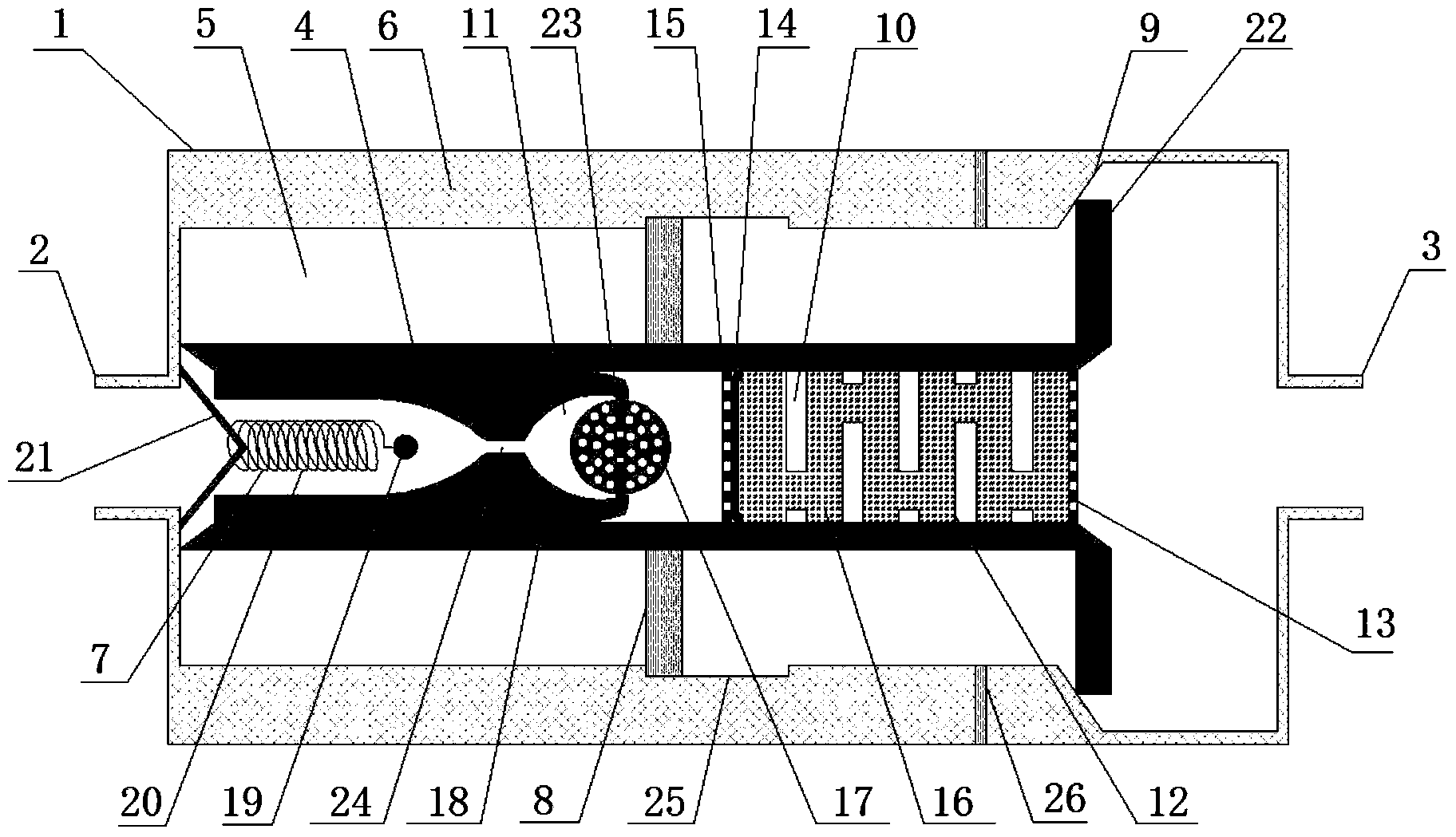

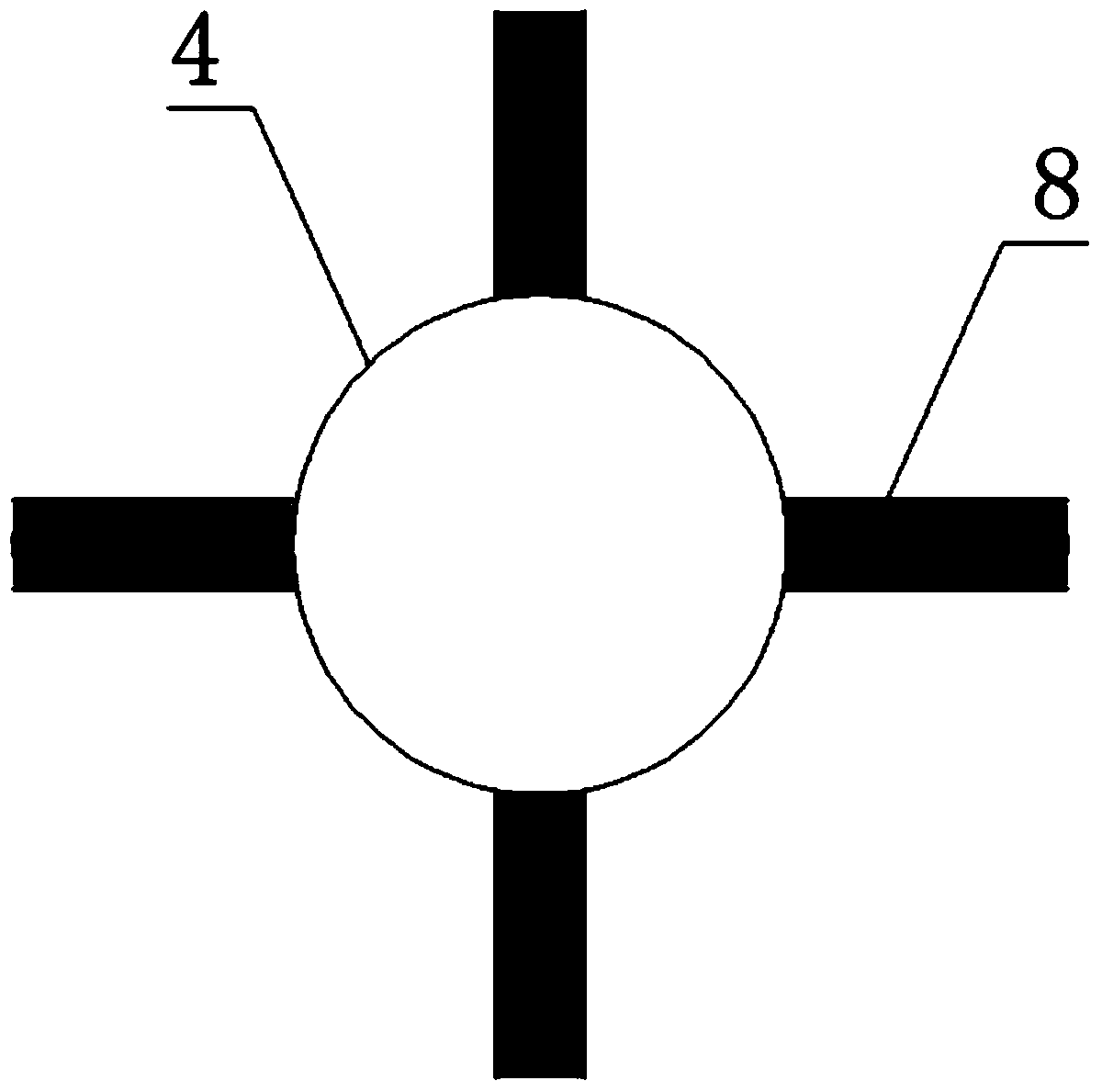

[0033] like figure 1 , 2 As shown, a switch control valve for the state of an aircraft cargo compartment fire extinguishing system includes a valve body 1, a high-speed inlet 2, and a low-speed inlet 3. The valve body is provided with a sliding valve core 4, a valve cavity 5, a valve seat 6, and an elastic control valve. The switch 7, the sliding valve core 4 is provided with a slider 8 on the outer periphery, and the end of the valve seat 6 close to the low-speed inlet 3 is a conical angled surface 9, and the valve chamber 5 is provided with a dry filter chamber 10 and a throttle chamber 11.

[0034]One end of the high-speed inlet 2 is connected with the release port of the fire extinguisher bottle 31 through the hi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com