Shielding plate for enhancing flow field uniformity

A shielding plate and uniformity technology, which is applied in the field of microelectronics, can solve problems such as uneven etching rate, and achieve the effects of improving distribution uniformity, improving flow field uniformity, and reducing pressure difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation of the shielding plate for improving flow field uniformity of the present invention will be described in further detail below in conjunction with the accompanying drawings, but it is not used to limit the scope of protection of the present invention.

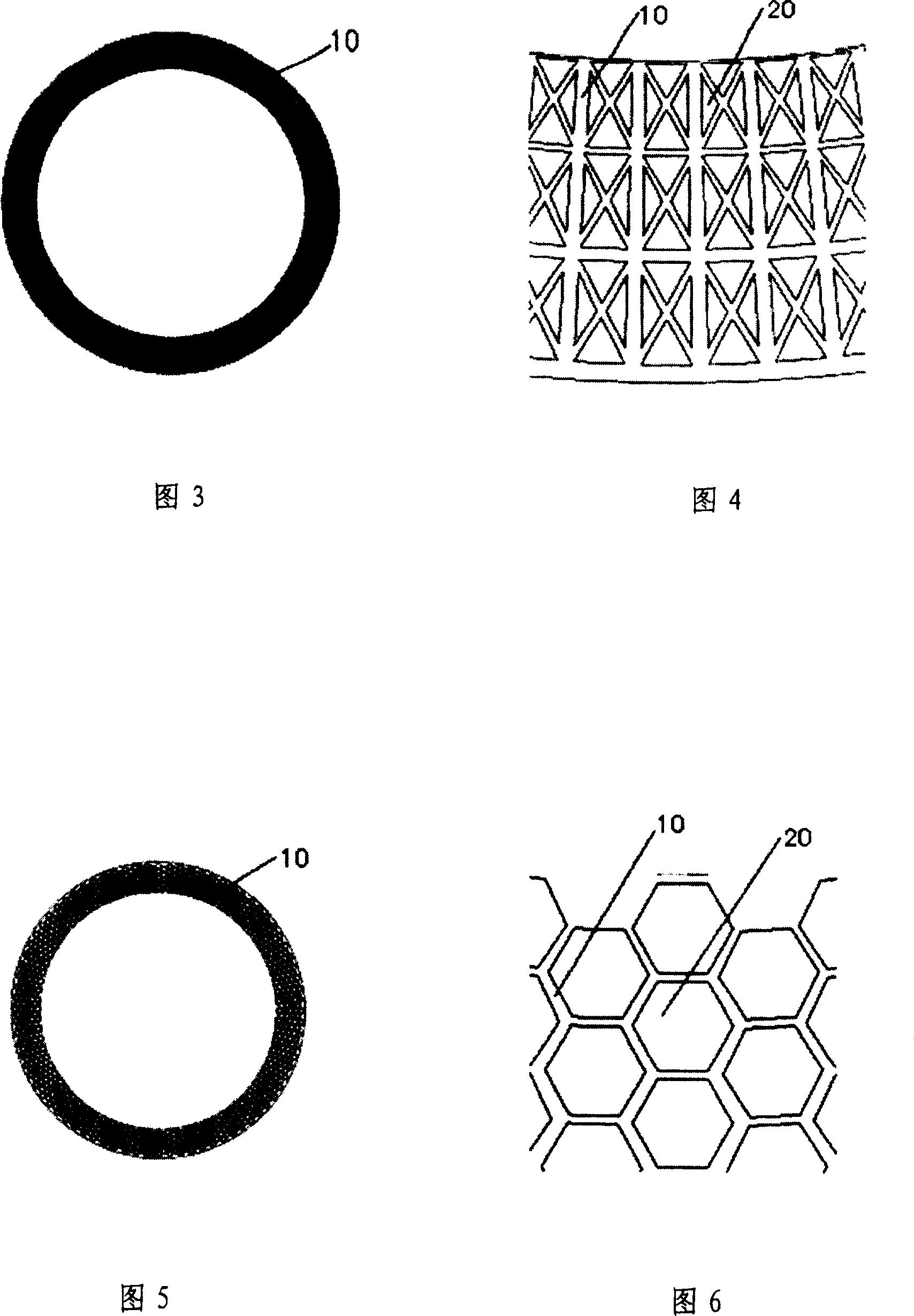

[0029] See Figures 3 and 4. The structure of the first embodiment of the shielding plate for improving the uniformity of the flow field of the present invention includes an annular plate body 1, on which a number of air holes are radially distributed from the center to the circumferential direction, and some air holes are formed from the plate body. 1 The center gradually becomes larger toward the circumference. The cross-sectional shape of the air hole is quadrilateral, and in each quadrilateral hole, a partition is respectively arranged along the two diagonals of the quadrilateral, and the quadrilateral air hole is divided into four triangular air holes, and the longitudinal section of each t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com