A kind of adsorption type bone apatite and its preparation method and application

A bone apatite, adsorption-type technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, phosphorus compounds, etc., can solve the problem of insufficient adsorption capacity of bone apatite, achieve low cost, improve adsorption rate, The effect of the preparation process is simple and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The process of the preparation method of the adsorption type bone apatite in this embodiment is as follows:

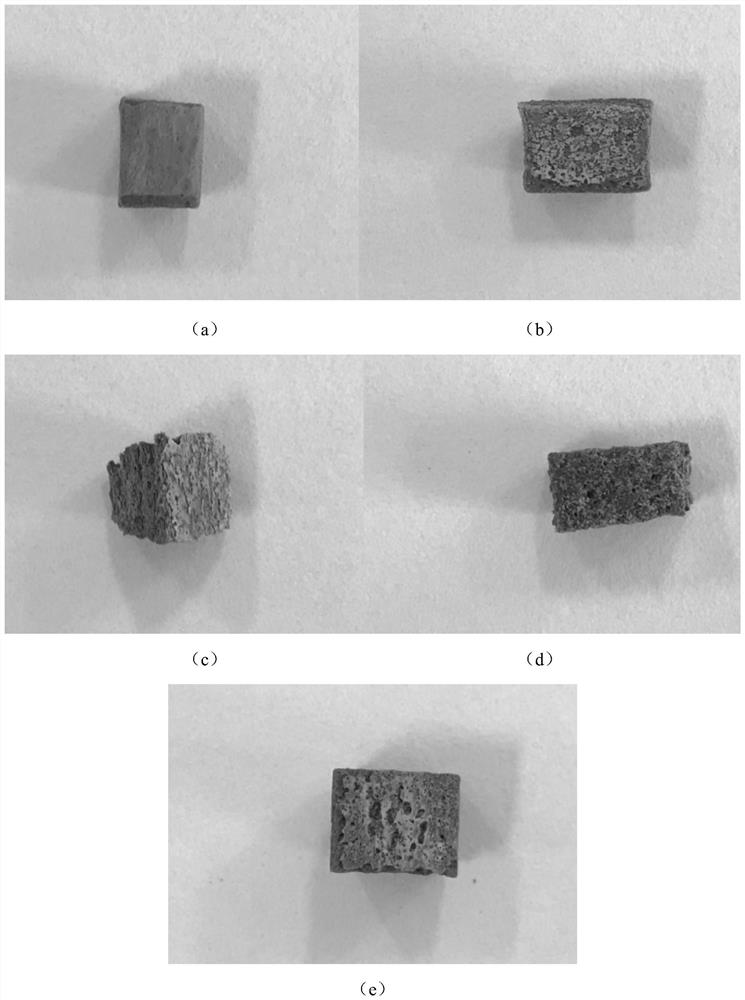

[0049] Cut the animal bone into block animal bones with a size of 1cm×1cm×1cm, soak the block animal bones in 30vol.% hydrogen peroxide for 24h, then boil in boiling water at a temperature of 100°C for 2h, repeat the boiling operation 3 times, each time Change the water again.

[0050] Then put the massive animal bone into a TC-12X2 muffle furnace for high-temperature calcination. The calcination temperature is 550°C, the heating rate is 5°C / min, the holding time is 5h, and the bone apatite is obtained by air cooling.

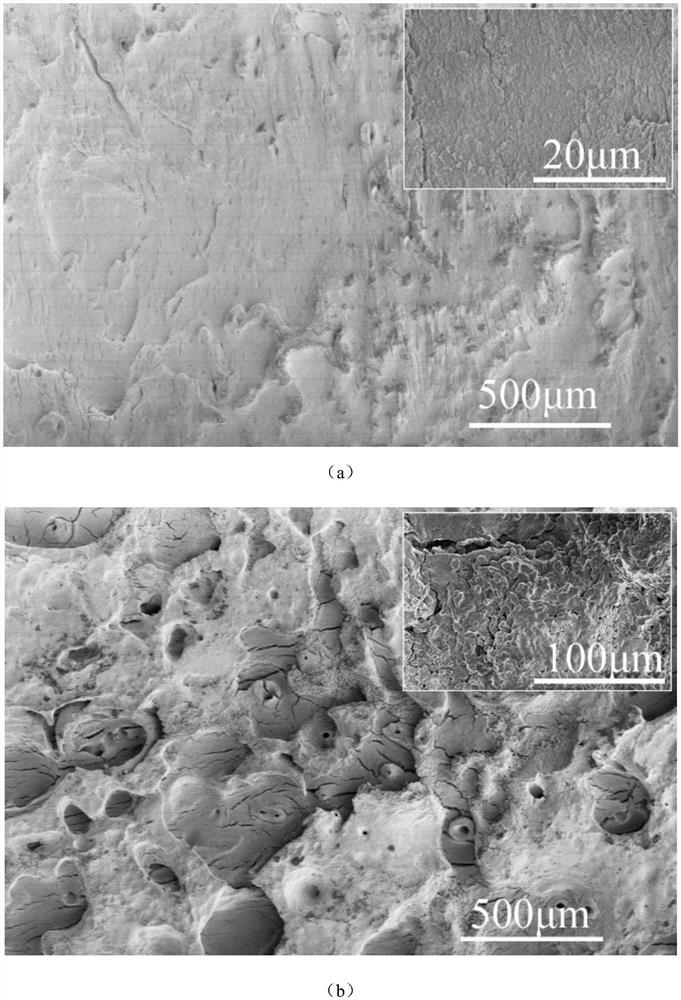

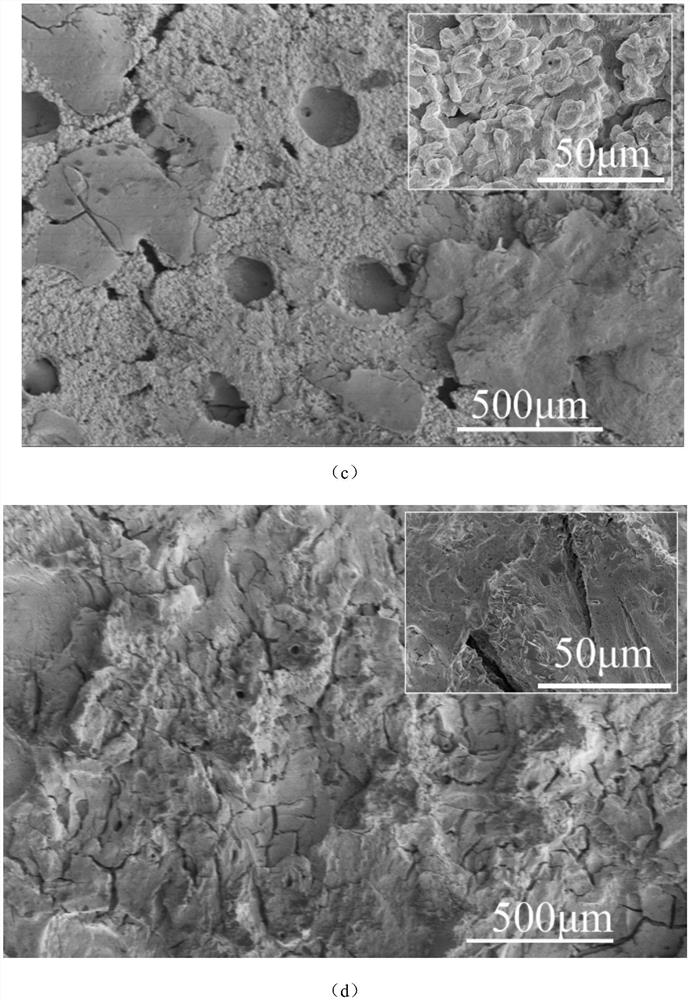

[0051] Bone apatite was modified by stationary phosphoric acid etching, and the surface of bone apatite (BHAP) was chemically modified. Eight blocks of bone apatite with a mass of 0.9 g were soaked in phosphoric acid solution. The phosphoric acid concentration in the phosphoric acid solution is 10vol.%, the acid etching time is 10min, and the ad...

Embodiment 2

[0055] The process of the preparation method of the adsorption type bone apatite in this embodiment is as follows:

[0056] Cut the animal bone into block animal bones with a size of 1cm×1cm×1cm, soak the block animal bones in 30vol.% hydrogen peroxide for 24h, then boil in boiling water at a temperature of 100°C for 2h, repeat the boiling operation 3 times, each time Change the water again.

[0057] Then put the massive animal bone into a TC-12X2 muffle furnace for high-temperature calcination. The calcination temperature is 600°C, the heating rate is 5°C / min, the holding time is 4h, and the bone apatite is obtained by air cooling.

[0058] Bone apatite was modified by stationary phosphoric acid etching, and the surface of bone apatite (BHAP) was chemically modified. Eight blocks of bone apatite with a mass of 0.9 g were soaked in phosphoric acid solution. The concentration of phosphoric acid in the phosphoric acid solution was 10vol.%, and the acid etching time was 40 minut...

Embodiment 3

[0062] The process of the preparation method of the adsorption type bone apatite in this embodiment is as follows:

[0063] Cut the animal bone into block animal bones with a size of 1cm×1cm×1cm, soak the block animal bones in 30vol.% hydrogen peroxide for 24h, then boil in boiling water at a temperature of 100°C for 2h, repeat the boiling operation 3 times, each time Change the water again.

[0064] Next, put the massive animal bone into a TC-12X2 muffle furnace for high-temperature calcination at a temperature of 600°C, a heating rate of 5°C / min, and a holding time of 4 hours to obtain bone apatite.

[0065] Bone apatite was modified by stationary phosphoric acid etching, and the surface of bone apatite (BHAP) was chemically modified. Eight blocks of bone apatite with a mass of 0.9 g were soaked in phosphoric acid solution. The concentration of phosphoric acid in the phosphoric acid solution was 10vol.%, and the acid etching time was 30 minutes to obtain adsorbed bone apati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com