Lightweight thermal insulation daub for coreless induction furnace, and preparation method thereof

An induction electric furnace, lightweight technology, applied in the field of casting and smelting, can solve the problems of large temperature difference between the hot surface and the cold surface of the working lining material, increase the electricity cost of the electric furnace manufacturer, and damage the working lining material, etc., so as to reduce penetration and improve use. Longevity, the effect of reducing the loss of induced heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

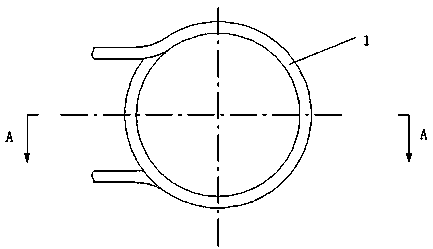

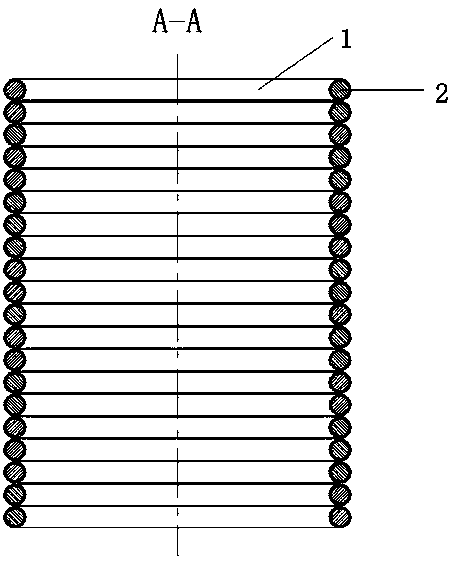

[0019] see Figure 1-2 , the present invention provides a technical solution: comprising lightweight thermal insulation mortar 1, said lightweight thermal insulation mortar 1 uniformly covers the outer layer of coreless induction furnace coil 2, and the main chemical component of said lightweight thermal insulation mortar 1 is Al2O3 : 65%-75%, SiO2: 17%-25%, CaO: 4%-6%, the preparation method of described lightweight thermal insulation mortar 1 comprises five steps altogether, and it is respectively: one, prepare raw material; Two, raw material Mixing; 3. Material testing; 4. Finished product packaging; 5. Application.

[0020] Step 1 in the preparation method of lightweight thermal insulation mortar 1: preparing raw materials. Its raw material and the ratio of each raw material component are:

[0021] Bauxite clinker 45%-55% (alumina content > 80%, particle size 0.045mm-3mm). Bauxite clinker is a common refractory raw material in industry, and its maximum service temperatu...

Embodiment 1

[0029]Example 1: Pour the finished lightweight thermal insulation cement 1 into a mixer and add water to mix. The amount of water added is 15% of the weight ratio of the material, and the mixer is started to mix for 10 minutes. Spread the uniformly mixed material on the coil 2 of the coreless induction furnace with a thickness of 30 mm. After 24 hours of natural curing (the curing temperature is 25°C), the working lining of the electric furnace is made. The results of use confirm that the temperature gradient of the cold and hot surface of the working lining of the electric furnace can be reduced by 180-200 ℃ compared with the traditional coil cement used before, which greatly improves the damage to the working lining material caused by the cold and heat shock, and prolongs the final service life of the working lining of the electric furnace. The original 105 heats have been increased to 132 heats. According to on-site feedback, the temperature of the outer steel shell of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com