Preparation method of SE-PERC solar cell with high conversion efficiency

A solar cell, high-conversion technology, applied in the field of solar cells, can solve the problems of easy exposure of PN junction, decreased cell conversion efficiency, and easy damage to the oxide layer, and achieves good passivation effect, conversion efficiency improvement, and cost reduction treatment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

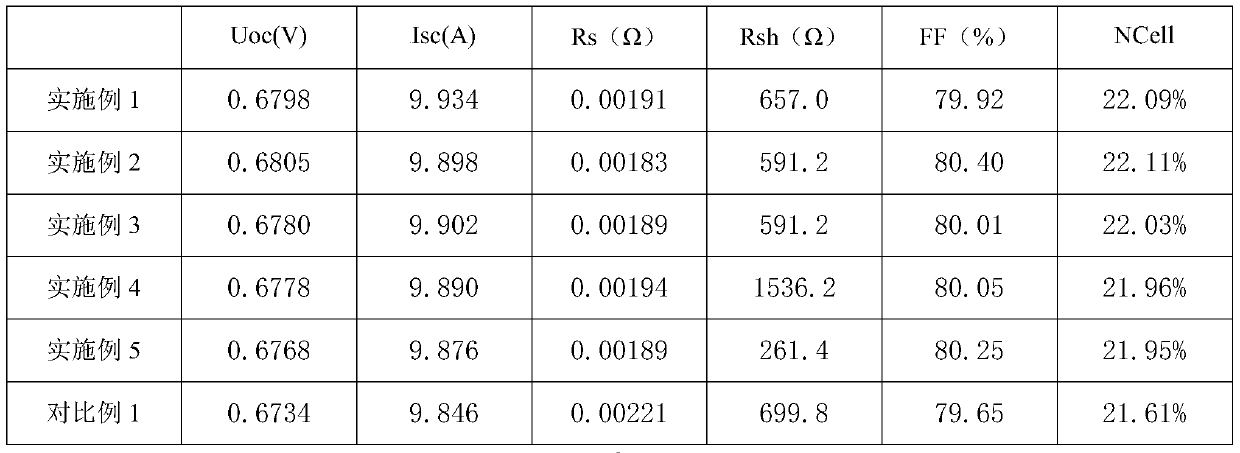

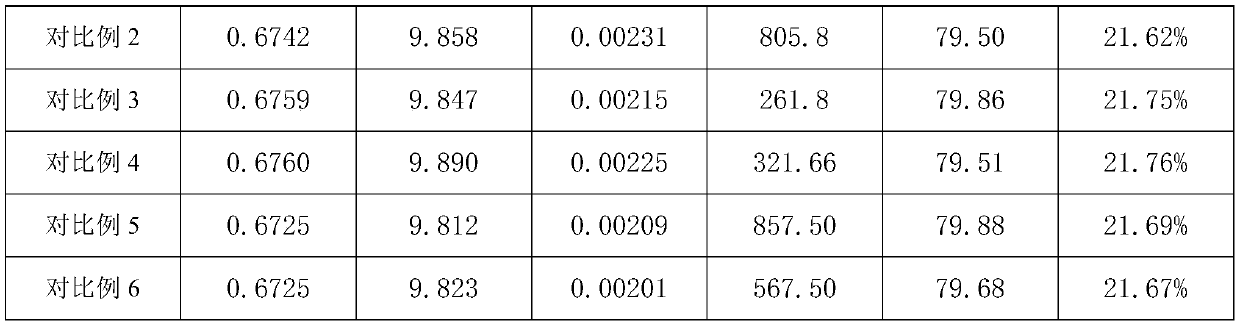

Examples

Embodiment 1

[0042] Embodiment 1: A kind of preparation method of high conversion efficiency SE-PERC solar cell, comprises the following preparation steps:

[0043] 1) Texture making: select 1000 P-type 1-3Ω·cm silicon wafers and use 7wt% hydrogen peroxide to remove oil and other impurities, and then use 3wt% sodium hydroxide solution and 1wt% sodium silicate solution to make texture. Form a textured surface on the surface of the silicon wafer; then use 7% HF solution and 10% HCL solution to remove impurities such as metal ions, wash and dry; the weight loss of the silicon wafer after texturing is 0.5g, and the reflectivity of the silicon wafer is 11%. ;

[0044] 2) Phosphorus diffusion: Phosphorus diffusion treatment is performed on the textured silicon wafer. The square resistance of the treated silicon wafer is 110Ω / □, and the junction depth is 50nm;

[0045] 3) Heavy laser doping: use DR laser machine to carry out laser heavy doping on the diffused silicon wafer, and the square resistan...

Embodiment 2

[0060] Embodiment 2: A kind of preparation method of high conversion efficiency SE-PERC solar cell, comprises the following preparation steps:

[0061] 1) Texture making: select 1000 P-type 1-3Ω·cm silicon wafers and use 15wt% hydrogen peroxide to remove oil and other impurities, and then use 1wt% sodium hydroxide solution and 2wt% sodium silicate solution to make texture. Form a textured surface on the surface of the silicon wafer; then use 9% HF solution and 13% HCL solution to remove impurities such as metal ions, wash and dry; the weight loss of the silicon wafer after texturing is 0.7g, and the reflectivity of the silicon wafer is 9%. ;

[0062] 2) Phosphorus diffusion: Phosphorus diffusion treatment is performed on the textured silicon wafer. The square resistance of the treated silicon wafer is 90Ω / □, and the junction depth is 10nm;

[0063] 3) Heavy laser doping: use Dill laser machine to carry out laser heavy doping on the diffused silicon wafer, and the square resis...

Embodiment 3

[0078] Embodiment 3: A kind of preparation method of high conversion efficiency SE-PERC solar cell, comprises the following preparation steps:

[0079] 1) Texture making: select 1000 P-type 1-3Ω·cm silicon wafers and use 5wt% hydrogen peroxide to remove impurities such as oil stains, and then use 5wt% sodium hydroxide solution and 3wt% sodium benzoate solution to make texture. Texture is formed on the surface of the silicon wafer; then 5% HF solution and 20% HCL solution are used to remove impurities such as metal ions, cleaned and dried; the weight loss of the silicon wafer after texturing is 0.4g, and the reflectivity of the silicon wafer is 12%;

[0080] 2) Phosphorus diffusion: Phosphorus diffusion treatment is performed on the textured silicon wafer. The square resistance of the treated silicon wafer is 130Ω / □, and the junction depth is 30nm;

[0081] 3) Heavy laser doping: use Dill laser machine to carry out laser heavy doping on the diffused silicon wafer, and the squar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Square resistance | aaaaa | aaaaa |

| Knot deep | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com