Phase change temperature control type high-voltage cable

A high-voltage cable, phase change temperature control technology, applied in the direction of insulated cables, power cables, cables, etc., can solve the problems of insulation drop, cable fire, uneven distribution, etc., to reduce transient temperature rise, improve service life, and increase heat dissipation effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

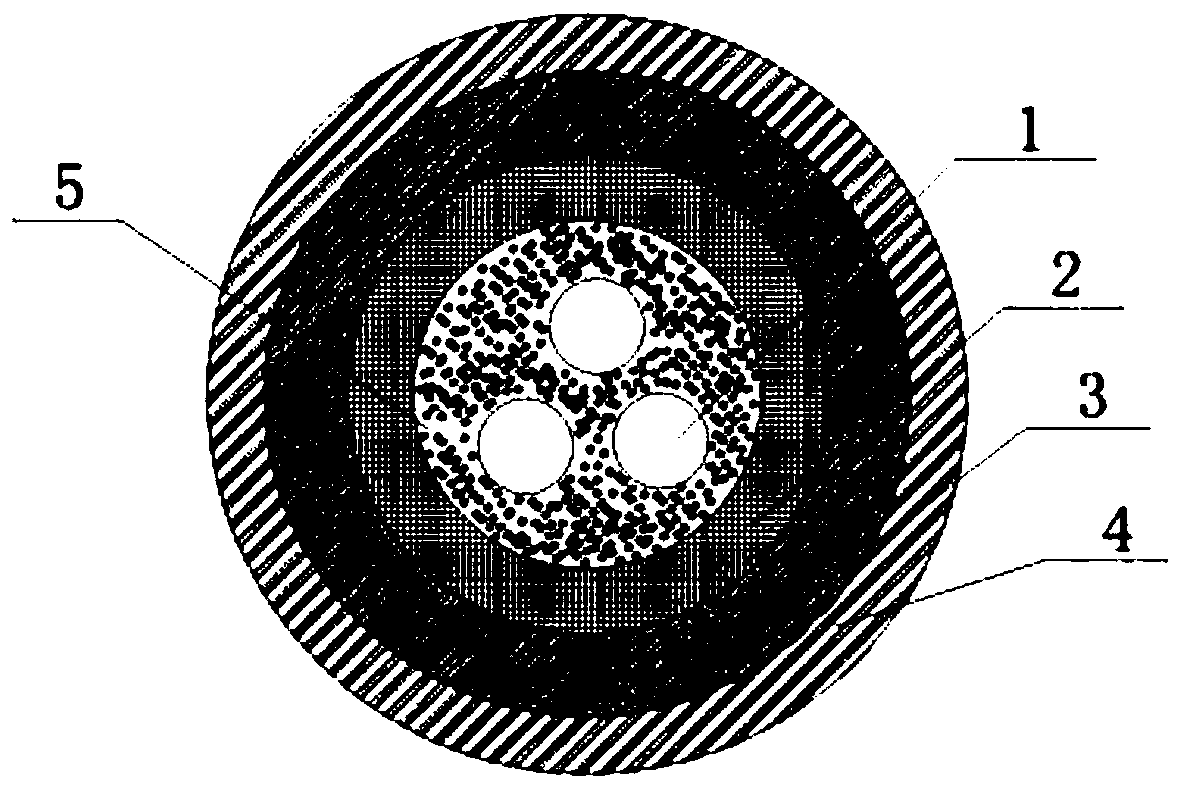

[0016] see figure 1 , a phase-change temperature-controlled high-voltage cable, including a cable core wire 1, a low-smoke halogen-free polyethylene inner sheath 2 coated on the outside of the cable core wire 1, and a braid layer 3 formed by interweaving superconducting carbon fiber filaments And the outer sheath 4 composed of interwoven carbon fiber wire and copper fiber wire, a filling layer 5 is provided between the cable core wire 1 and the inner sheath 2, and the filling layer 5 is expanded graphite-high Density polyethylene-paraffin composite phase change microcapsules. Described expanded graphite-high-density polyethylene-paraffin wax composite phase-change microcapsule mass ratio is: expanded graphite: high-density polyethylene: paraffin=1:3:6, described expanded graphite-high-density polyethylene-paraffin wax composite The shell of the phase change microcapsule is polyurea resin.

Embodiment 2

[0018] see figure 1 , a phase-change temperature-controlled high-voltage cable, including a cable core wire 1, a low-smoke halogen-free polyethylene inner sheath 2 coated on the outside of the cable core wire 1, and a braid layer 3 formed by interweaving superconducting carbon fiber filaments And the outer sheath 4 composed of interwoven carbon fiber wire and copper fiber wire, a filling layer 5 is provided between the cable core wire 1 and the inner sheath 2, and the filling layer 5 is expanded graphite-high Density polyethylene-paraffin wax composite phase-change microcapsules, the mass ratio of the expanded graphite-high-density polyethylene-paraffin wax composite phase-change microcapsules is: expanded graphite: high-density polyethylene: paraffin wax=2:1:7, the described The shell of the expanded graphite-high-density polyethylene-paraffin composite phase change microcapsule is polyurea resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com