A kind of composite coating steel and preparation method thereof

A technology of composite coating and coated steel, applied in chemical instruments and methods, coatings, layered products, etc., can solve problems such as insufficient anti-corrosion performance, difficulty in meeting the requirements of high corrosion-resistant steel, and damage to the steel plate substrate. The effects of high coating resistance to peeling strength, low coating surface defect rate, and excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] Based on the same inventive concept, the application also provides a preparation method of composite coated steel, said method comprising:

[0040] surface-treating the steel substrate;

[0041] Coating an intermediate layer containing the components on the upper surface of the surface-treated steel substrate to obtain steel containing the intermediate layer;

[0042] coating the upper surface of the intermediate layer containing the intermediate layer steel to obtain composite coated steel.

[0043] In the present application, the coating method is hot-dip coating, and the hot-dip coating temperature is 400-700°C.

[0044] In the present application, the surface treatment includes at least one of the following: removing iron from the surface and removing scale from the surface.

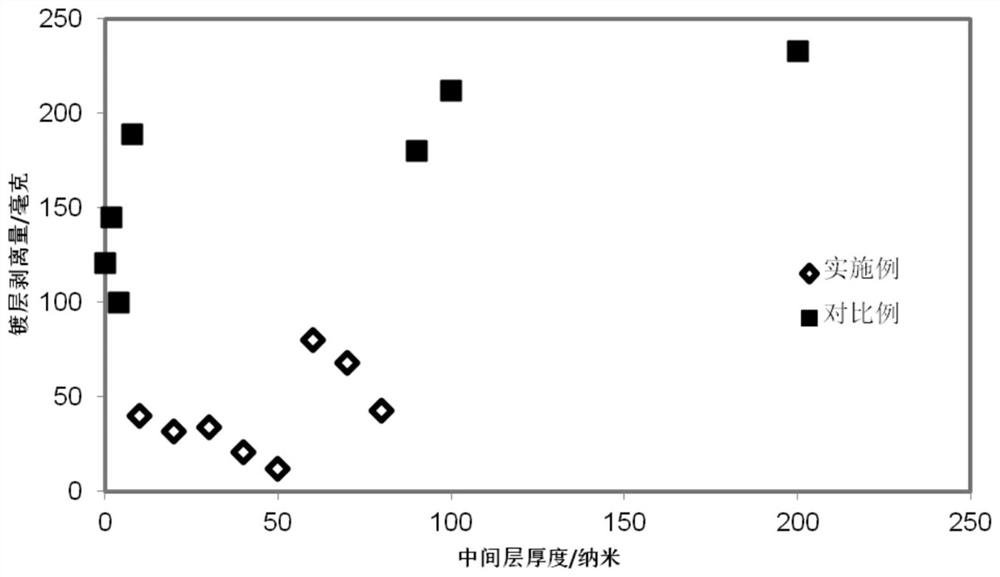

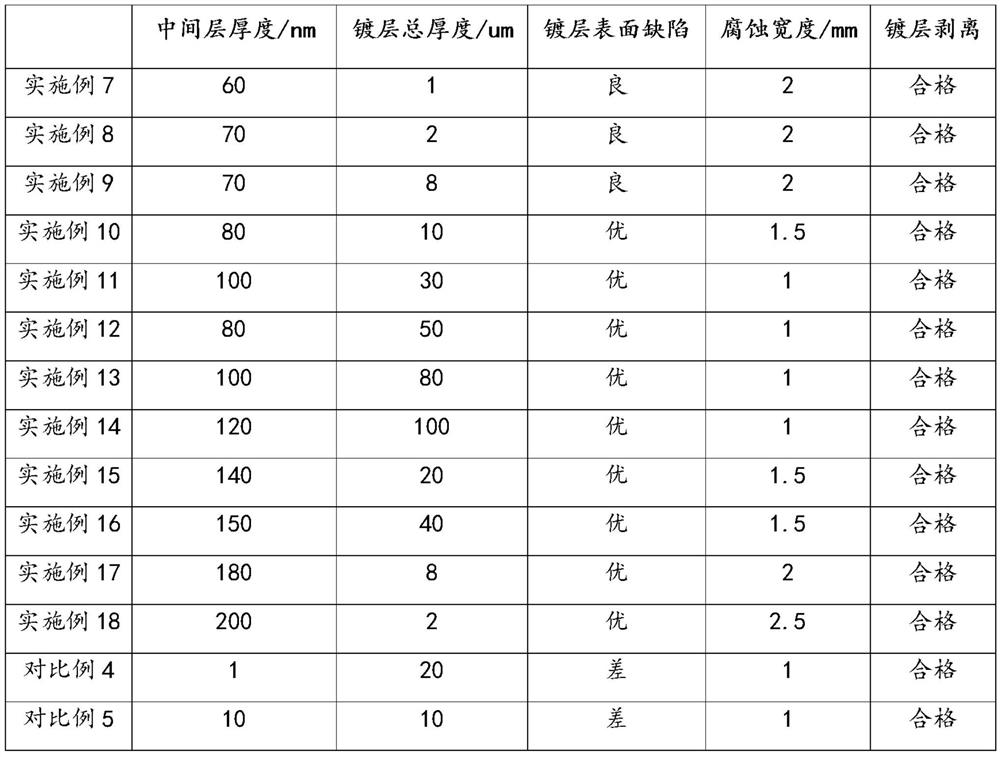

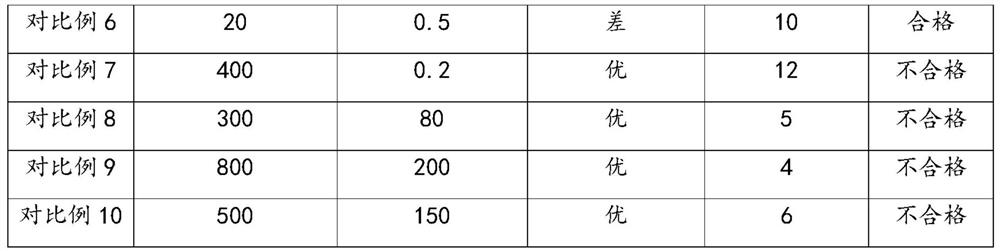

[0045] The thickness of the intermediate layer of the composite coated steel provided in the embodiment of the present invention is 10-200 nanometers. The role of the intermediate layer is ...

Embodiment 1

[0051] This embodiment provides a composite coated steel, the coated steel includes a steel base, an intermediate layer and a coating, the intermediate layer is located between the steel base and the coating.

[0052] Specifically, the intermediate layer is nickel.

[0053] Specifically, the number of layers of the middle layer is 1.

[0054] Specifically, the thickness of the intermediate layer is 200nm

[0055] Specifically, the coating is a galvanized layer.

[0056] Specifically, the total thickness of the coating is 10um.

[0057] Specifically, the steel matrix is hot-rolled pickled steel.

[0058] Specifically, by weight percentage, the chemical composition of the steel matrix is as follows: 0.2% C, 0.2% Si, 1.2% Mn, 0.01% S, 0.01% P, 0.08% Al, and the rest are Fe and unavoidable impurity elements .

[0059] Specifically, the steel matrix has a thickness of 1.50mm and a width of 1200mm.

[0060] Based on the same inventive concept, embodiments of the present in...

Embodiment 2

[0065] This embodiment provides a composite coated steel, the coated steel includes a steel base, an intermediate layer and a coating, the intermediate layer is located between the steel base and the coating.

[0066] Specifically, the material of the intermediate layer is nickel-cobalt and nickel-copper alloy, the weight percentage of nickel in the nickel-cobalt alloy is 50%, and the weight percentage of nickel in the nickel-copper alloy is 20%.

[0067] Specifically, the number of layers of the middle layer is 2.

[0068] Specifically, the thickness of the intermediate layer is 10nm

[0069] Specifically, the coating is a galvanized aluminum layer.

[0070] Specifically, the total thickness of the coating is 100um.

[0071] Specifically, the steel matrix is cold-rolled steel.

[0072] Specifically, by weight percentage, the chemical composition of the steel matrix is as follows: 0.02% C, 0.05% Si, 2% Mn, 0.05% S, 0.02% P, 0.6% Al, and the rest are Fe and unavoidable i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com